Timing Belt Pulley

A timing belt pulley is part of the timing belt system for an automobile. A timing belt is one way to control the opening and closing of engine valves by connecting the crankshaft to the camshaft of the vehicle. Generally, the timing belt does this by having teeth that lock into the teeth of the two gears for the crankshaft and camshaft.

A timing belt is one of several belts used in conventional cars and other vehicles. A serpentine belt is a belt that drives various other engine accessories off of the crankshaft. The serpentine belt can run an alternator, power steering pump, and air conditioning compressor. In some vehicles, these jobs are split between multiple belts, where a vehicle usually has only one timing belt pulley.

Each belt in a vehicle may have additional pulleys to route it around the engine compartment. An idler pulley is a pulley that provides movement for the belt but does not run an accessory or engine component. A timing belt idler pulley may help provide additional track routing for the belt. The idler timing belt pulley may also be called a tensioner pulley if it helps to provide tension on the belt. A tensioner pulley is one that a vehicle owner or mechanic can adjust to change the amount of tension on the belt when needed.

A timing belt is a very crucial part of engine operation. Damage or malfunctioning of the timing belt will be a serious impediment to driving the vehicle. Those who experience problems with the timing belt of a vehicle should consult a professional mechanic who can calibrate and fix the timing belt properly for regular operation of the vehicle.

Though most drivers prefer to let experienced mechanics work on any idler or tensioner timing belt pulleys when belts are having problems, others can learn how to do basic work on their vehicles including how to change tension on a belt by moving the pulley. Most tensioner pulley setups will include several bolts that hold the pulley in place. The person working on the vehicle can loosen the bolts, then adjust tension by either moving the pulley along a threaded bolt, or prying it toward or away from the engine block.

Individual vehicle owners often look at how to replace a serpentine belt or a timing belt pulley for their specific car, truck or other vehicle. Each model of car or vehicle has its own specific setup for serpentine and timing belts and the pulleys involved. Lots of vehicles have routing diagrams for belts, either on decals under the hood or in the owner’s manual.

There are several advantages for selection of TIMER BELT PULLEY DRIVES :

- Timer belt drives are positive grip devices. There is no chordal rise or fall of pitch line, no slippage and no belt creeps. This belt require no lubrication because there is no metal to metal contact and the noise level is low in normal speed range.

- Cost is always and important advantage and the initial cost is usually the only expense involved. Thus, Timer belt drives are an economical means of power transmission.

- Timer belts have a speed range from inches per hour to approximately 16.000 fpm. Small pitch belt can transmit positive motion while operating at high speed. Speed in excess of 8000 fpm are generally impractical for large pitch belts.

- Power capacity of Timer belt drive ranges from subfractional to approximately 800 hp. The drive must be belted to transmit the power required by the highest load encountered.

- Special functions, Many Timer belts drives are used for functional rather than power transmission application. Because they travel with predictable positive, nonslip, precision, designers have created a variety of devices. As example, anguler drive, triangular drive, squre drive, deflection drives, multi shaft drive, reversing drive, conveyor belt drive etc. Also tubing cut-off system, fabricating cartons, elevator conveyor for ball bearing, drive track for snow mobile etc.

|

|

Our Products

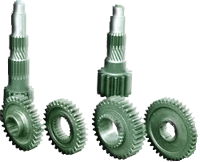

Spur Gears Spur Gears

Helical Gear Helical Gear

Sprocket Sprocket

Worm and worm wheel Worm and worm wheel

Racks and Pinion Racks and Pinion

Bevel Gears Bevel Gears

Timing Belt Pulley Timing Belt Pulley

|