Milling

Milling is one of the important processes in industry. It is commonly used to reduce the size of solid and Active Ingredients in pharmaceuticals. The primary benefit of milling and reduction of particle size is better absorption of the drugs in the Human System due to increase in surface area.

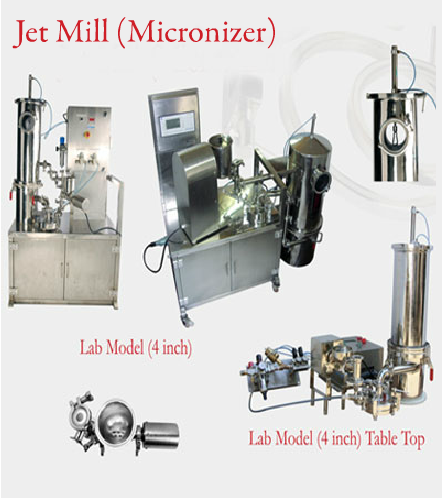

Jet Mill (Micronizer)

Air Jet Mill Micronizer is machine that effectively reduces particle size by particle to particle collusions with limited metal to product contact and no generation of heat.

| APPLICATIONS | SALENT FEATURES |

| • Particle size reduction from 100 micron to less than5 micron • Used for crystalline, amorphous, or agglomerated products, colour pigments, heat sensitive products etc. • Also used for hard meterial milling such as ceramic and glass etc. |

• Compliane to Indian FDA and USFDA rules and in accordance with cGMP specification • Flameproof and Non Flameproof Construction. • Fully Automatic • Single Unit Compact Design • Short path for product conveyance • Portable Unit |

Multi Mill

Multi Mill is a mechanical impact machine that effectively reduces particle size with the help of rotating blades.

APPLICATIONS

• Particle size reduction from lump of 50mm to 100micron

• Used for crystalline, amorphous or agglomerated products

• Widely used in the pharmaceutical, chemical, food, ceramic, colours and cosmetic industries

SALENT FEATURES.

• Portable Unit

• Easy to Operate and Clean

• GMP Mode in Pharma and Food Industries

• FLP Model for hazardous application

• Speed Variation by VFD