POWDER SPRAY BOOTH

The powder spray booth basic I, is ideally suited for coating individual parts of small production runs and also works extremely economically in spray to waste mode. The work pieces are hung at front and coated manually. The powder spray stand comes into its own when normal and large items have to be coated in connection with conveyor systems.

SPRAY GUN

MEGASTATIC manual powder coating equipment is designed for optimum efficiency with minimum maintenance. The electrostatic spray gun is designed light weight and easy in operation having maximum flexibility. A specially designed electrode & nozzle ensures maximum charging of powder particles so as to have maximum transfer efficiency of powder.

OVEN

MEGASTATIC Oven specially designed for less heat energy consumption and uniform temperature. The dynamically and statically balanced blower provided at the top of oven for effective and uniform heat circulation resulting in better finish of the job. A suitably designed control panel with digital temperature control. The ovens are available with

Liquid Spray

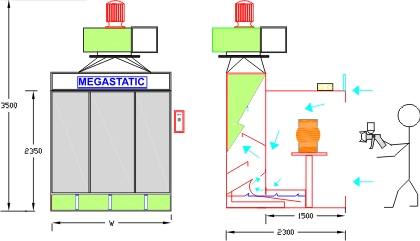

The main function of liquid paint spray booth is to keep the environment free from vapors to exhaust the solvent vapors to atmosphere, to direct the spray towards the job and to kill the overspread paint and to convert it in easily disposable form. The Spray booth is basically in two parts spray zone and eliminator section.

Recent News

Liquid Spray Painting Booth

The main function of liquid paint spray booth is to keep the environment free from vapors to exhaust the solvent vapors to atmosphere, to direct the spray towards the job and to kill the overspread paint and to convert it in easily disposable form.

CONSTRUCTION

The Spray booth is basically in two parts spray zone and eliminator section. The panels of Paint booth are made out of 14 gauge preformed sheet steel. The main water tank made out of 10 gauge. thick steel sheets duly cleaned and treated and primered. For easy assembly these panels are connected with each other with the help of nut bolts. Suitable illumination is provided in the spray area.

The elimination section comprises of Bottom water Tank, "C" plate, Baffle plates, Exhaust blower & Motor, Bottom water tank in which specially designed "C" Plate is fitted, is filled with water and booth chemical. While working, due to suction caused by air-blower, a whirl is formed on the "C" plate and due to this whirl booth chemicals start their action. At first solvent is separated form the paint, which is exhausted to atmosphere and the resin particles of the paint are then encapsulated with mineral oil and after reaction with booth chemicals get sopeni fide and ultimately settles down in the form like sponge. The over sprayed water particles get caught in baffle plates, specially designed for this purpose. Thus we achieved the requirements of safer atmosphere, eliminate the fire hazard, and make the residue easily

A thick paper is pasted with the help of grease is applied to prevent paint deposition on the screen and easy cleaning. The air velocity of 1 mt/sec. around the job gives the best result in paint consumption and quality. The airflow is so adjusted in the spray zone that all the overspread paint is directed towards the elimination chamber only. This results in comfort of the painter.

Technical Specification

| Sr. No. | W mm | Air Exhaust cu.m./hr. | Motor H.P. |

| 1 | 2400 | 21600 | 7.5 |

| 2 | 3600 | 32400 | 10 |

| 3 | 4800 | 43200 | 2 x 10 |

| 4 | 6000 | 54000 | 4 x 7.5 |