Our Products

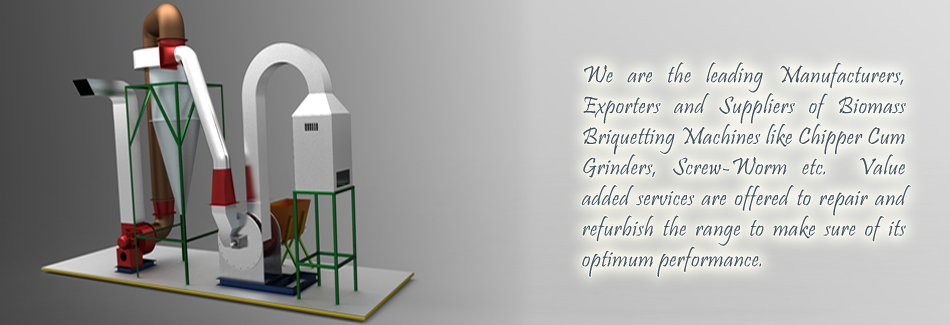

- - Biomass Briquetting Machines

- + Agriculture Machinery

>Chipper Cum Grinders

>Hammer Mill Grinder

>Briquetting Press

>Screw-Worm

>Vibrating Screen

>Flash Dryer & Material Handling

>Rotary Drum Dryers

Contact Us

Guru Nanak Agro IndustriesMr. Hardeep Singh

V. P. O. Lehra, Near Dehlon

Ludhiana, Punjab - 141 118, India

Telephone: +(91)-(161)-2885232

Biomass Briquetting Machines

Briquettes are normally produced in machines with a Briquettes diameter between 40MM to 100 MM in round. Briquetting Press is Piston type mechanical press with two fly wheels. One fly wheel is driven by V belts with motor. Filtered & cooled lubrication oil is supplied by oil pump through p. pipes. The central lubrication system gives long life buses and crank, piston and other inner parts. Material is pushed in feeding chamber by vertical screw with own geared motor from feeding chamber material is compressed by ram through taper bore die. Briquettes are formed in the shape of logs and it is automatically pushed through cooling line to the storage point.

We are making press different production range

1. 40 mm 250-350 kg/hr.

2. 50mm 400-600 kg/hr.

3. 60mm 600-900 kg/hr.

4. 70mm 800-1350 kg/hr.

5. 90mm 1600-2300 kg/hr.

6. 100mm 2000-2800 kg/hr.

All machines production capacities depend on raw material

Chipper Cum Grinders

Chipper cum Grinder which chips & Grinds the long material(Dry & Wet) into required size for briquetting in single action

Hammer Mill Grinder

Hammer Mill Grinder has large diameter dynamically balanced rotor. its body is made from tested plate. alloy steel shaft. For long life bearings are width, dust protected and fitted away from grinding body.Grinding blades are fitted with rotor at bottom screen is fitted for particular size of ground material. ite able to run machine conutinully.

Electricity:

- 40 HP

- 2 HP

- CAPACITY

- 1

- 1

- 1600 Kg/Hour

Briquetting Press

Briquetting Press:- Press is Piston type mechanical press with two fly wheels. One fly wheel is driven by V belts with moter.filtered & cooled lubrication oil is supplied by oil pump through p. pipes. Material is pushed in feeding chamber by vertical screw with own geared motor from feeding chamber material is compressed by ram through taper bore die by compression temperature rises and lignin come to the surface and binds the material by its natural binder. Briquettes are formed in the shape of logs and it is automatically pushed through cooling line to the storage point.

Screw-Worm

We are engaged in offering a vast range of screw worms, which is compact highly durable. Distribute, Collect, Mix and Control material flow in processing operations as per required machine Capcity.

Vibrating Screen

Flash Dryer & Material Handling

Flash Dryer is designed to reduce moisture from 50%to 10% which is suitable for briquetting. Material after vibrating screening put in flash drier through screw conyver and heavy duty blower pick up the material with hot air which produce from hot air generator. Material comes in pneumatic cyclone attached with airlock. Blower drop material in cyclone and it passes it to holding bins which is fitted on briquetting press. after Dust is collected by cyclone. By screw conveyor material is discharged from holding bin to the Briquetting Press.

We are making press different production range

40 mm 250-350 kg/hr.

50mm 400-600 kg/hr.

60mm 600-900 kg/hr.

70mm 800-1350 kg/hr.

90mm 1800-2100 kg/hr.

production of machine depend on raw material.

We have in store, Material Handling Equipment for our customers. Our precisely engineered range of material handling is used in various applications of different industries. This simple to use equipment make the material handling task easy and time saving. Reckoned for low maintenance, this equipment is fabricated as per the international quality standards. Our customers can purchase it from us at competitive prices.

Rotary Drum Dryers

We manufacture and supply superior quality Rotary Drum Dryer, which is fabricated using high grade components and latest process technology. Our drum dryer is available in three different models such as double drum dryers, single drum dryers and cooling drum dryers. It has gained appreciation amidst our customers for their quality attributes like corrosion resistance and longer service life.