Our Products

Contact Us

Guru Nanak Agro IndustriesMr. Hardeep Singh

V. P. O. Lehra, Near Dehlon

Ludhiana, Punjab - 141 118, India

Telephone: +(91)-(161)-2885232

Profile

We introduce ourselves as a leading manufacturer of Biomass Fuel Briquetting Plants and Biofuel Briquettes. We are in this field since 1988 Our Firm SURJIT SINGH DARSHAN SINGH since 1974; the firm was started with a main object of setting up a Saw Mill. After years to use Saw Mill waste(saw dust, wood chip and shavings, leaves & trash) as fuel We were convinced with Briquetting technology and we started manufacturing machinery for fuel briquettes in year 1986.Ultimately with his own mind and ideas a machine was ready after long struggle and machine was installed in our own plant in 1988. We are in this field since 1988 then various alterations ware made to improve the productivity. Thus we have rich experiences of years in the line of manufacturing of Briquettes and Briquetting Machinery.

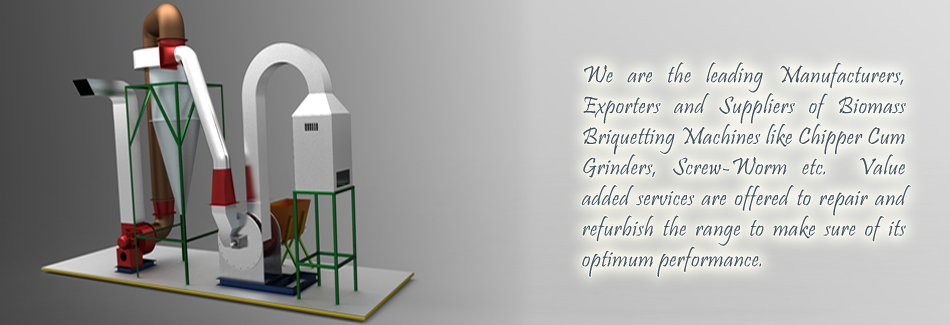

Established in the year 1997, at Lehra, Ludhiana, (Punjab, India), we, “Lehra Energy Resources Pvt. Ltd.,” are a well-known name engaged in manufacturing and supplying a widespread range of Biomass Briquetting Machines like Chipper Cum Grinders, Screw-Worm etc. In our extensive product assortment, we manufacture and supply of Chipper Cum Grinders, Flash Dryer & Material Handlings, Hammer Mill Grinder, Vibrating Machine, Briquetting Press, Rotary Drum Dryer and Screw-Worm.

High end quality examination facilities and the latest infrastructural facilities have made us capable of fabricating and supplying products in compliance with the international standards of quality. Bestowed, with a hardworking team, Our Company have been able to compile our products with the highest standards of quality and precision. We have been targeting on complete contentment of quality conscious clients across the Indian Subcontinent.

Inspired under the productive leadership of our mentor, S. Darshan Singh, we have reached an unmatched status in the industry. His solid industry acquaintance and dedication levels have ensured us to deliver high quality Biomass Briquetting Machinery at the most competitive prices in the industry.

Company Profile

Basic Information

- Business Type

- Supplier

- Manufacturer

- Exporter

Ownership & Capital

- Year of Establishment

- Ownership Type

- 1997

- Limited Liability/Corporation (Privately Held)

Trade & Market

- Major Markets

- Annual Turnover

- Indian Subcontinent

- Upto US$ 0.25 Million (or upto Rs. 1 Crore Approx.)

Team & Staff

- Total Number of Employees

- 11 to 25 People

Company USP

- Provide After Sales Support

- Primary Competitive Advantage

- Quality Measures/Testing Facilities

- User Manual

- Experienced R & D Department

- Large Product Line

- Large Production Capacity

- Provide Customized Solutions

- Yes

Packaging/Payment and Shipment Details

- Customized Packaging

- Payment Mode

- Yes

- Cash

- Cheque

Promoters

S.DARSHAN SINGH LEHRA

I am the Managing Director of Lehra Energy Resources Pvt. Ltd. Since 1997. I was started a firm in 1974 with the main object of setting up a Saw Mill. I was convinced with the briquetting technology and I started manufacturing machinery for briquettes and machine was ready after long struggle and machine made briquettes. I have a rich experience in the line of manufacturing of briquetting machinery and fuel briquettes.

At present I am president of PUNJAB & HARYANA AGRO WASTE FUEL BRIQUETTER’S ASSOCIATION, head office vpo. Lehra Ludhiana Punjab India.

Product Portfolio

We are into manufacturing and supplying Biomass Briquetting Machines of the highest quality for our customers spread all over the Indian Subcontinent. We manufacture and deal only in globally unique products of the best finish and designs. Our products are inspected for their quality specifications, reliability and firmness at our high end and state-of-the-art fabrication units. As a result, we are competent to fabricate and export products that are hassle free to operate, effective and long-lasting.

We offer:

Chipper Cum Grinders

Flash Dryer & Material Handlings

Hammer Mill Grinder

Vibrating Machine

Briquetting Press

Rotary Drum Tillers

Screw-Worm

Salient Features:

Highly dependable

Robust manufacture

Long service lives

Cost competency

Fuel Briquettes

Energy is the key factor in the Economic development and the requirement of the energy will increase and as the resources being limited there is all round search of alternatives resources of the energy and energy sources.

The product FUEL BRIQUETTES has a specialization of being pollution free property and high calorific value which is the need of time and in this critical period. Briquetted fuel as an ideal and ready substitute to Coal, Fire Wood, Charcoal, Lignite etc the fuel offers numerous advantages as mentioned below, other than consistent quality and economical prices :-

1. High calorific value ranging between 3000-5200 Kcal/kg depending on the material used.

2. Low fly ash contents of 2-10% as compared to 20-40% in Coal.

3. Non polluting as it does not emit any sulphur or phosphorus fumes and low fly ash.

4. As it produces from agro waste this is Eco friendly Fuel. Cheaper than coal as it utilizes waste and residues usually disposed off at no or low cost.

5. Loose material has a 100kg./m. cu. Of bulk density on the other Briquettes have a bulk density of 1000-1300kg./m. cu. And easy to handle or transport.

The concept of Briquetting is physical transformation of the loose material into a compactly compressed unit. The form change results in a much higher specific density of the material which increases its combustion, efficiency as compared to the loose material. It also considerably reduces storage and transportation costs. The following agricultural and forest waste and saw mills waste and residues can easily be converted into Fuel Briquettes.

Which material can be used?

Agro Waste – Mustard waste, Rice husk, Groundnut shell, Pine needles, Coffee husk, Sunflower & waste, Sugarcane bagasse, leaves& trash, Maize stalks

Forest waste – Wood chips and shavings, Tree bark and twigs, Saw dust, Bamboo leaves, Wild grasses, Shrubs.

For a successful briquetting the raw material when feeder to the particle size must be less than 10mm and Moisture content of raw material must be 5% to 20%.

Manufacturing Procces

Raw material like as saw dust, dung is screened and stalks (Forest & Agro waste) are grinded by Cutter Chipper after that grind by Grinder. For using material of two or more type, it should be mixed in suitable form. if material has high moisture it should be reduced by sun drying and Flash Drier. By Screw Conveyor, raw material is transported into pneumatic convey line in the presence of hot air. Dried material is collected by cyclone and the air lock system drop to holding bins fixed over briquetting press. Dust is collected by cyclone. By screw conveyor material is discharged from bin to the Briquetting Press. Material is compressed by ram through taper bore die by compression temperature rises and lignin come to the surface and binds the material by its natural binder. Briquettes are formed in the shape of logs and it is automatically pushed through cooling line to the storage point.

Our Infrastructure

Supplying in accordance to the varying demands of our customers, we have set up the most contemporary infrastructural unit, which is segmented into various divisions, namely manufacturing unit, quality control unit, and research and development facility. Helping us in the trouble free functioning of the entire process, all the departments are equipped with highly modernized equipment for fabricating a quality assortment of products. The products manufactured at the fabrication department are inspected by our quality examiners to eradicate any defects. We invest in the research and development department to guarantee a higher and technically modernized assortment for our clients across the country.

We possess a team of superiorly qualified professionals, who are one of the eminent reasons for our ability to meet the varying demands of our clientele across the nation. With years of competent experience to our credit, our team is talented enough to precisely meet the demands of our customers to achieve the highest levels of client contentment. In addition to this, we have to comprehend the specific needs of customers that would enable us to guide and instruct our team accordingly.

Our Quality Assurance

With the objective to promise the highest levels of quality of the products fabricated by us, we have framed a uniquely designed quality analysis department. The department comprises experienced and skilled professionals, who strictly observe the whole fabrication procedure to terminate manufacturing flaws and defects caused during manufacturing and processing of our products. To ensure that our products supplied to the customers are error free, they are examined on various specifications, such as:

- Performance

- Durability

- Maintenance

- Corrosion resistance

Markets

The demand for fuel briquettes comes from the shortage of non-conventional fuels such as coal, oil, firewood etc. and their escalating prices. There is crying need for an economical and renewable sources of energy. The gap between demand and supply is very wide and the country has been facing a chronic energy shortage for several years . depletion of forest resources and rampant use of firewood in rural areas has reduced the availability of woody biomass. Thus fuel briquettes can be used by the industrial, commercial, fireplaces, boilers and household sectors. It is ideally suited for the use in following areas:-

1. Boilers :- Sugar Mills, Paper Mills, Chemical Plants, Dying Houses, Food processing units, Oil Extraction units, Vanaspati Unit etc. using fuel for steam generation and heating.

2. Forges and foundries : for heating and melting of iron and steel.

3. Brick Kilns and Ceramic units : for firing furnaces and brick.

4. Residential and Commercial : for winter heating in cold areas, Houses of Hill Station and in Hotels, Motels Restaurants, Canteens and Dhaba for cooking foods.

5. Gasification : use of fuel briquettes in gasifiers for production of producer gas have shown very encouraging results and can used to drive engines, generator sets and to produce heat for replacement of oil firing furnaces.

One of the most important advantages of this fuel is that it can be produced in any part of the country and can contribute substantially to the development of rural economy.

Why Us?

We possess a high end manufacturing unit, we have been capable of garnering and extensive clientele across the domestic and international markets as a consequence of our high quality compilation of products offered by us. Moreover, our transparent business transactions and client centered approach have played a significant role in placing ourselves as a dependable and highly efficient organization.

Following are the factors that have made us the choicest manufacturers and suppliers across the markets of the Indian Subcontinent:

- Superior quality range of products

- Advanced manufacturing facility

- Dedicated and skilled team of personnel

- Customized solutions

- Wide distribution network

- Industry leading prices