Fitting

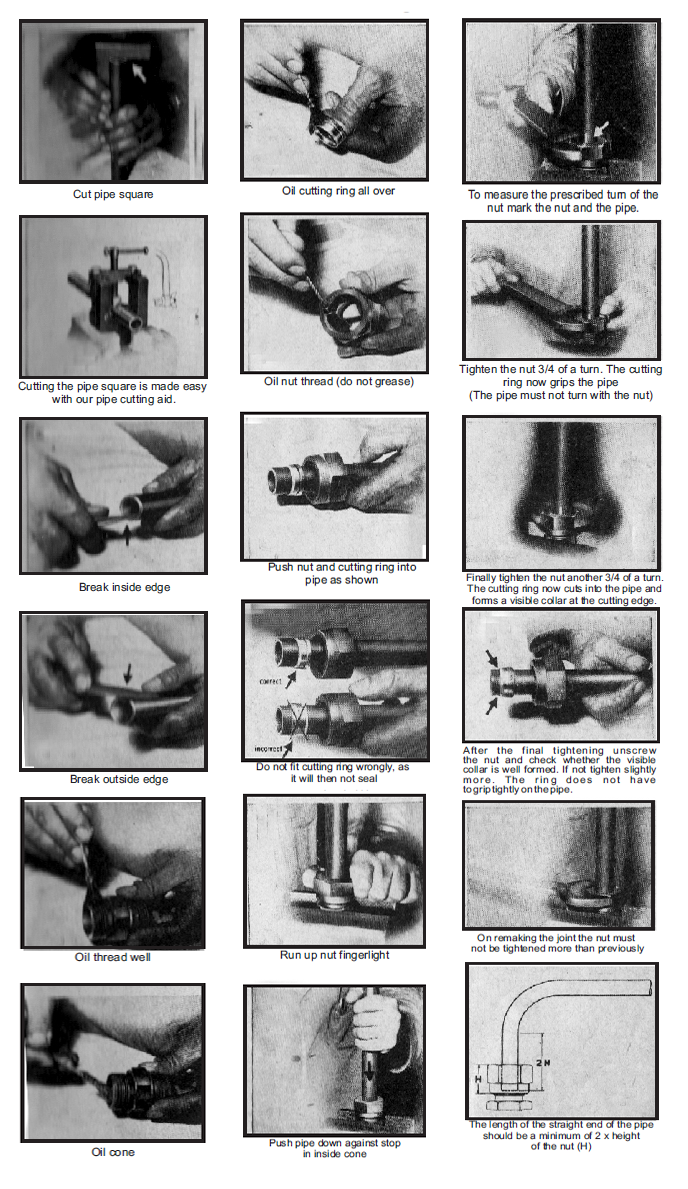

I - Cutting off the pipe at rightangles is facilitated

by using the pipe sawing device shown in the illustration on the

left, which is for pipes having an external diameter from 6 to 42

mm.

I - Cutting off the pipe at rightangles is facilitated

by using the pipe sawing device shown in the illustration on the

left, which is for pipes having an external diameter from 6 to 42

mm.

Part No. :AV 6/42

ATTENTION : Do not use pipe cutters !

Pipe wall is not cut rightangled.

II - Well oil (not grease) the threads and cutting ring. Then push the

nut and the ring over the end of the pipe as shown in the illustration.

II - Well oil (not grease) the threads and cutting ring. Then push the

nut and the ring over the end of the pipe as shown in the illustration.

If it is impossible or very difficult to

puch the cutting ring over the end

of the pipe, do not open out the

cutting ring but file the end of the

pipe to make it a little thinner.

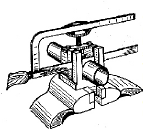

III - Pipes of a smaller external diameter can be fitted

direct into the couplings if they are screwed into

appliances. First of all, tighten up the nut by hand

until you can feel that it is binding on the cutting

ring. Then press the pipe against the stop in the

inner cone and tighten the nut by about threequarters

of a turn.

Make sure that

you do not turn the

pipe round with it.

This makes the

cutting ring grip

the pipe, after

which it is no

longer necessary to press the pipe.

For the final tightening give the nut another three

quarters of a turn. When this is done the ring cuts

into the pipe and pushes up a visible coller in front

of the cutting edge.

III - Pipes of a smaller external diameter can be fitted

direct into the couplings if they are screwed into

appliances. First of all, tighten up the nut by hand

until you can feel that it is binding on the cutting

ring. Then press the pipe against the stop in the

inner cone and tighten the nut by about threequarters

of a turn.

Make sure that

you do not turn the

pipe round with it.

This makes the

cutting ring grip

the pipe, after

which it is no

longer necessary to press the pipe.

For the final tightening give the nut another three

quarters of a turn. When this is done the ring cuts

into the pipe and pushes up a visible coller in front

of the cutting edge.

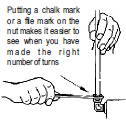

IV - Pipes having a larger external diameter and all

couplings which have to be made in free pipes

are best given a pre-installation in the vice. The

length of the spanner should be about 15 times

the diameter the nut (if necessary extend it by

slipping a pipe. For that you can use a special

hardened pre-installation body which must be

inspected permanently a gauge !

IV - Pipes having a larger external diameter and all

couplings which have to be made in free pipes

are best given a pre-installation in the vice. The

length of the spanner should be about 15 times

the diameter the nut (if necessary extend it by

slipping a pipe. For that you can use a special

hardened pre-installation body which must be

inspected permanently a gauge !

If you use a serical body in connection with the

installation, take care that each pipe end is

always fitted in the same inner cone

with which the pre-installation was

carried out.

The final tightening is made easier if

the nut is loosened a few times so

that fresh oil can get between the

friction surfaces.

V - When the final tightening been

carried out, undo the nut again

and check up to see weather

the visible collar thrown up fills

the space in front of the cut. If

not, tighten it up a little more.

It does not matter if the cutting

ring can be turned round on

the end of the pipe.

V - When the final tightening been

carried out, undo the nut again

and check up to see weather

the visible collar thrown up fills

the space in front of the cut. If

not, tighten it up a little more.

It does not matter if the cutting

ring can be turned round on

the end of the pipe.

After the

joined has been completed

and after each time it is

tightened up without any

extension on the spanner

handle and without using any

abnormal force.

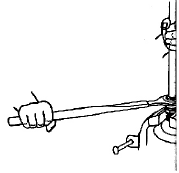

The s t raight pipe end

projecting into the coupling

must have a minimum length

which is twice the height of the

nut (H). In the case of long pipe

mains and those subjected to

high stresses it is necessary

for pipe clips to be fitted.

The s t raight pipe end

projecting into the coupling

must have a minimum length

which is twice the height of the

nut (H). In the case of long pipe

mains and those subjected to

high stresses it is necessary

for pipe clips to be fitted.

Adjustable couplings (evW, evT, evL, evGE) as well as KOR are delivered pre-installed at the stand pipe side. The final installation will be made in the respectively body with at least 1/2 turn after you have felt perceotible resistance.