Pipe Couplings

General :

This leaflet only contains pipe couplings and accessories which have been

found after years of experience to be those generally required on the market, and are

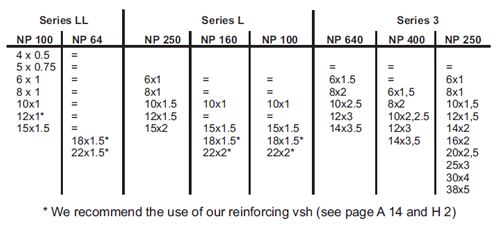

manufactured in bulk in three types according to DIN 2353 :

very light = LL, light = L and heavy = S.

For special models, particularly couplings for higher pressures, we recommend that in

the first instance the advice of our technical department or our agencies be obtained.

Absolute reliability can only be guaranteed for HEP pipe couplings if HEP - parts are

exclusively used, and if they are fitted in accordance with the unstructions (see page A

12 and A 13). Fitting instructions for workshops may be had on request.HEP - original

parts are stamped with our trade mark.HEP

Standardisation :

HEP - pipe couplings are supplied in accordance with DIN Standard

specification 2353 (Summary). Screw-in couplings are deliverable with Whitworth

pipe thread and metrical thread. Screw-in holes belonging to these couplings see

page A 15 and A 16. Foreign standards can only be used in connection with screw-in

threads. e.g. NPT - screw-in threads.

The Whitworth threads (R) indicated in this catalogue are BSP (T) threads, e.g. type

GE 12-LR means a coupling with BSP parallel screw-in thread.

Material and Surface Protection :

* HEP- pipe couplings of steel for steel pipes : - drawn and forged

nuts : - cold-resp. warm-pressed (highest safety).

* HEP - pipe couplings of brass for copper pipes :- forged and drawn of seawater resistant quality Cu Zn 35 Ni (So MS 59)

* HEP - pipe couplings of stainless and acid-proof steel for stainless and acid-proof pipes : - drawn and forged.

* HEP - pipe couplings of heat-resistant steel : - on demand

Surface Protection :

* Pipe couplings of steel : (standard) for series L and S

Exceptions see indications in the catalogue.

bodies and nuts phosphated and oiled,

cutting and locking rings cadmium-plated.

* Series LL : galvanic zinked, transparent bichromated

* On demand :

a) glavanic zinked, ransparent bichromated

(short symbol : A 2K)

b) cadmium- plated and chromated

(short symbol : B 2A)

C) galvanic zinked and yellow chromated

(short symbol : A 2L)

Please and short symbol to the part No.

f. i.: GE 25-SR-A 2K

Part No. :

The part Nos. mentioned in this catalogue refer to parts made of steel.

They refer to complete parts.

A body as single part is marked with “X”, f.i. :

complete coupling GE 20-SR

body without nut (m)

and cutting and locking ring (d) X GE 20-SR

In case another material* is requested, please add to the part Nos. of the

catalogue the following symbols :

for couplings made of Cu Zn 35 Ni ......................................................... Ms

for couplings made of stainless and acid-proof steel ....................... 1.4571

for couplings made of special materials ...................................... W. Nr.......

* (please note the indications on the different catalogue pages with regard to special

materials!)

Pressures :

The pressures stated in the catalogue are nominal pressures, with a safety

factor of at least 4:1. These figures may be used as the maximum working pressures

under normal working conditions and temperatures up to 1200 C. In case of higher

temperatures and in instances where there ate sudden increases pressure and high

mechanical stress (vibrations etc.) we recommend the series (see under-mentioned

fields of application).

The test pressure should be 50% higher than the working pressure (see DIN

2401 for fuller details). It is assumed that the pipes and equipment will be clamped

position in such a way that the couplings will be free from any additional stresses loads

and tensions.

Recommendations :

Pipe couplings : In general we recommend the use of HEP - pipe couplings for.

Series LL : for pneumatic systems, hydraulic runback systems

propane, oil heating, vehicle industry, small-type

refrigerating machines, synthetic piping etc.

Series L : as the series LL, but in case of higher mechanical

stresses, pressure piping, etc.

Series S : heavy industry, shipbuilding, mining, chemical

industry, big-type refrigerating machines, pressure

piping etc.

Pipes : We recommend for our HEP - pipe couplings our HEP- seamless

precision steel pipes, according to DIN 2391/C, made of material

of special, quality, protective-gas / special-clean-annealed, free

of scale (NBK), phosphated / oiled, with tightness test.

Pipes : We recommend for our HEP - pipe couplings our HEP- seamless

precision steel pipes, according to DIN 2391/C, made of material

of special, quality, protective-gas / special-clean-annealed, free

of scale (NBK), phosphated / oiled, with tightness test.

The pressures given in the table below for the minimum wall

thickness stated, without any addition for corrosion, are based on

a safety of 4 x.

Conversion Table :

1 psi = 0,0703 kp/cm21kp/cm2 = 14,223 psi

10C = 1,80 F 10F = 0,5550C

Unit-composed system :

Standard types (couplings, such as GE, W, SV, etc) and the unit- composed parts :

* ri - (screw - in thread reducing pieces)

* KOR (cone reductions)

* evGE (adjustable straight made stud bodies)

* evW, T, L, (adjustable W-, T-, L- bodies)

* mav-ev (adjustable bodies for Manometer

connectiion)

* form a system, which in many cases allows a rational and compact installation.

Besides that the application od this unit-composed system is economical, because a

voluminious stock holding can be avoided.

Our unit-complsed system is based on the following combinations

1. evGE + basic type (f.i. W, T, K, RHD, etc)

With this combination you can form an adjustable screw-in coupling.

2. KOR + basic type (all bodies with cones)

Unit - composed part KOR enables reductions at the cone side.

3. ri + basic type (all types with R-screw -in-thread)

With the help of the reducing pieces ri the screw-in thread can be adapted to the

dimension of the screw-in hole.

4. evW- T-L + basic type (all types with cones)

Adjustable W-T-,L- bodies can be assembled with the basic types as well as with the

adjustable bodies among themselves, f.i. :

evW + Xge = EVW page C 14

evT + Xge = EVT page C 15

evL + Xge = EVL page C 16

In case of special materials, such as brass, stainless and acid- proof materials, only

the combination evGE + basic type is deliverable.