Heat energy is basically transferred into the product through a jacketed vessel wall causing solvents or moisture residues to evaporate. A rotating screw orbits along the vessel wall and helps the vapours to escape to the surface, at the same time providing a frequent exchange of particles in contact with the heated surface.

A Vacuum system keeps the vessel under constant vacuum and removes vapours from the vessel. Entrained dust particles are separated in a filter mounted above the dryer.

Heat energy is basically transferred into the product through a jacketed vessel wall causing solvents or moisture residues to evaporate. A rotating screw orbits along the vessel wall and helps the vapours to escape to the surface, at the same time providing a frequent exchange of particles in contact with the heated surface.

A Vacuum system keeps the vessel under constant vacuum and removes vapours from the vessel. Entrained dust particles are separated in a filter mounted above the dryer.

Features Of Nauta Dryer :

- Fast drying times as the mixing screw continuously circulates the product from the bottom to the top of the vessel improving heat transfer conditions.

- Final moisture after drying is possible down to 0%.

- Low energy consumption.

- Gentle to product.

- Quick and efficient removal of vapours.

- Recovery of pure solvents is possible.

- Dried solids are suitable for direct use.

- Easy to clean.

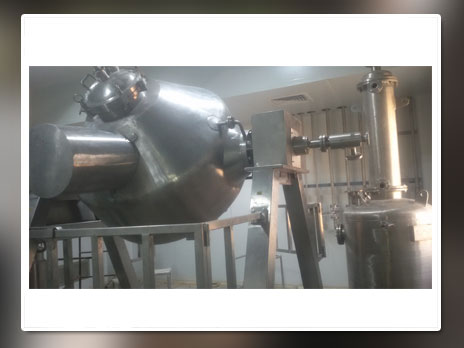

Wet feed is charged as a batch and is subjected to indirect heating while undergoing agitation due to the action of paddle mixing, The operation isnormally carried out in vacuum. Recovery of solvent is possible by condensing the vapours generated during the drying operation.

Wet feed is charged as a batch and is subjected to indirect heating while undergoing agitation due to the action of paddle mixing, The operation isnormally carried out in vacuum. Recovery of solvent is possible by condensing the vapours generated during the drying operation.

Features Of Rotary Vacuum Dryer :

- High energy efficient .

- Mode of heating is indirect.

- Conduction drying.

- System is batch .

- Granular / pasty wet materials can be handled.

- Low temperature operation is possible.

- Solvent recovery can be carried out.