We supply used ribbon mixers and industrial mixers of all types to the food, pharmaceutical, nutraceutical, flavors, ingredients, baking, fruit and beverage and other processing industries. We also supply these mixers to the chemical and mining processing industries including talc, barite, coal, limestone, gold mining, cement, lime, sand and gravel, etc. We supply brand new sanitary stainless steel double ribbon mixers to be used in the food processing, pharmaceutical processing, nutraceutical processing, and chemical processing industries.

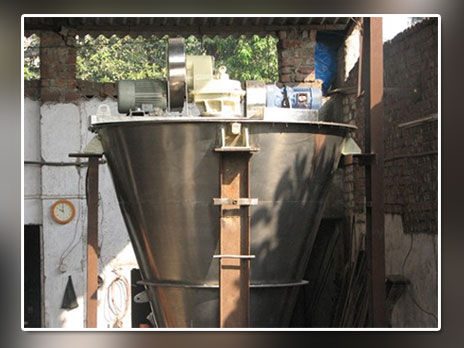

The conical mixer relies on a three dimensional action produced by a turning screw which itself rotates around the wall of a conical vessel.

The conical mixer relies on a three dimensional action produced by a turning screw which itself rotates around the wall of a conical vessel.

Features Of Conical Mixer :

- Gentle action on the product through low power consumption.

- Fast mixing times with a high degree of mixing accuracy.

- Minimum heat generation.

- Self emptying with minimum product retention.

- Volumes range from 5 - 6000 litres.

Applications :

- Mixing and homogenisation of powders, pastes and slurries.

- Addition or injection of liquids into dry solids.

- Granulation or agglomeration of powders by the addition of a binder liquid.

- Crystallisation.

- DCooling or heating.

The field of usefulness of Double cone for rapid, homogeneous blending and efficient drying is practically unlimited. As blender gently revolves a folding, spreading action ensures thorough uniform mixing, irrespective of material proportions or number of materials charged. Addition of liquid line & atomizer which remains stationary can give controlled uniform addition of liquid to dry powder. To avoid formation of lumps or re aggregation, internal lump breaker of different types can also be provided.

The field of usefulness of Double cone for rapid, homogeneous blending and efficient drying is practically unlimited. As blender gently revolves a folding, spreading action ensures thorough uniform mixing, irrespective of material proportions or number of materials charged. Addition of liquid line & atomizer which remains stationary can give controlled uniform addition of liquid to dry powder. To avoid formation of lumps or re aggregation, internal lump breaker of different types can also be provided.

Features Of Double Cone Blender :

- GMP compliant.

- Contact parts manufactured in Stainless Steel.

- The "Double Cone" ensures good rolling and Cross mixing.

- A-shaped frames provide stability of structure.

- Main drive provided with Variable Frequency Drive to control Blender RPM.

- Smart-stop arrangement to ensure that the Blender always stops in an upright position.

- Internal baffles ensure good blending and break lumps.

- Guard rails are provided with limit switch for safety.

Mixers engineered specifically for high shear blending, kneading, granulating need of pharmaceutical industry. Consistently identical batches are produced with shortest batch time & hence minimal energy consumption.

Mixers engineered specifically for high shear blending, kneading, granulating need of pharmaceutical industry. Consistently identical batches are produced with shortest batch time & hence minimal energy consumption.

The main impeller having precise minimal clearance with flat bottom of processing bowl in combination with chopper mounted on side wall, gives desired high shear mixing.

Features Of Rapid Mixer Granulator :

- GMP Compliant Model.

- Flame proof construction.

- Customised Layout.

- Unit with peristaltic pump for binder solution spray.

- Direct-coupled motor for belt less drive.

- Mechanical seal at chopper & Main Motor.

- Vacuum Transfer Arrangement to load Raw material.

- Unit with loading through inbuilt mechanical loader.