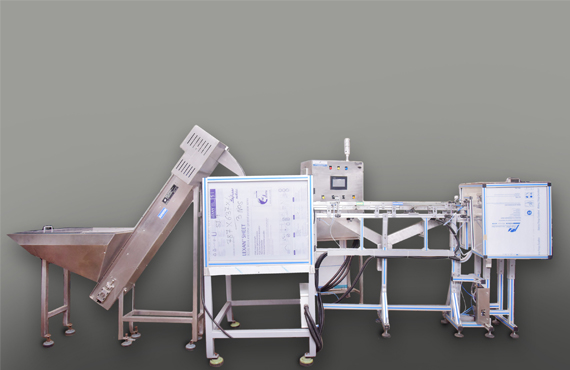

Buffing automation is specially designed for polishing electrical switch with full automation and can be use for all types of switches with minor change over & setting. Machine Features :

- Auto loading and unloading of components.

- High speed buffing.

- Buffing wheel height Adjustment.

- Safety canopy Enclosure.

- 60 Switch Per min buffing.

- Manless Operation.

- Safety starts push button.

- Easy Maintenance for all parts.

- PLC Base Control Panel.

- Automatic detect faulty and broken switch.