Advance Controllers (SIMATIC S7-300)

Introduction, Application, Benefits :-

Machine and plant constructors are being increasingly requested to offer more flexible and productive machines at reduced prices. This places new demands on the automation systems with respect to e.g. scope of functions, processing speed and size, as well as engineering and networking. PLCs are required with a large scope of functions and high processing speeds in a compact design. The networking facilities should be improved at the same time, but the engineering requirements should be simultaneously reduced.

SIMATIC® S7-300® is the most widely sold PLC within the context of Totally Integrated Automation with many successful reference applications worldwide found in many different industrial sectors. S7-300 users profit from the experience and global servicing facilities of the market leader as well as the quality associated with SIMATIC. This is the basis for increasing profits and improving competitiveness using innovative automation solutions.

The S7-300 has been designed for system solutions with the emphasis on production engineering, and is a universal automation platform providing optimum solutions for applications with central or distributed designs. Permanent innovations upgrade this automation platform even further. Examples include regular further development of the powerful CPU modules whose range now also includes a CPU with integral Ethernet / PROFlnet interface for Component based Automation.

Application:-

The SIMATIC S7-300 offers solutions for the most diverse automation tasks in the following areas :

Special Application:-

Design and Networking :-

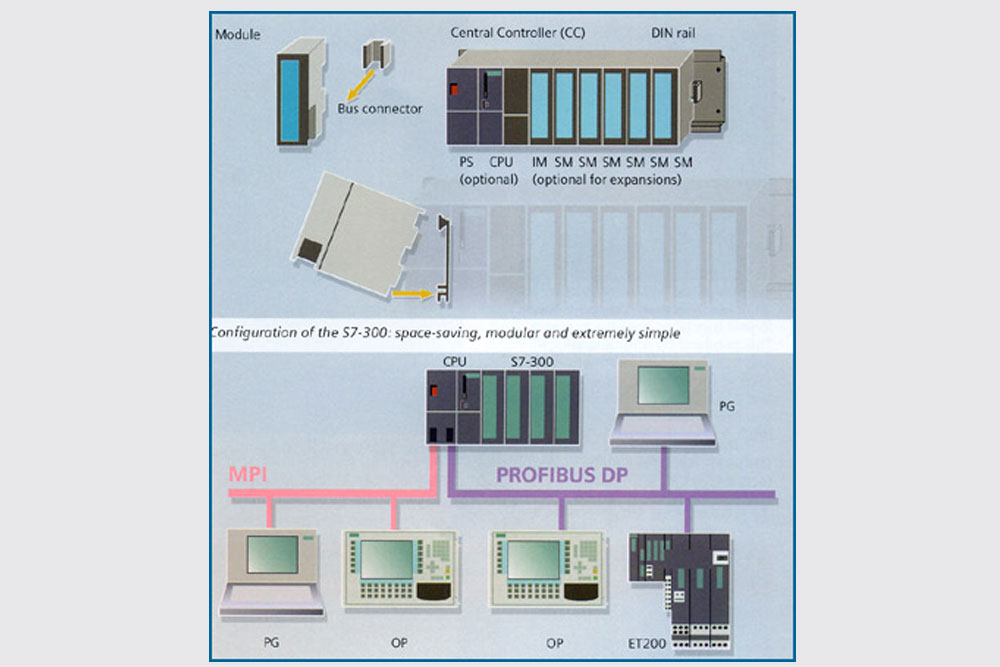

The S7-300 enables a space-saving modular configuration to machine controllers adapted to the task at hand, without taking slot rules into consideration. A fan is not necessary during operation. Apart from the modules, only a DIN rail is required where the modules are swung into place and secured by screws. A configuration is then possible which is robust and electro-magnetically compatible.

The backplane bus is integrated into the module and is assembled by insertion in the bus connector. The diverse S7-300 module spectrum can be used for centralized expansions as well as for simple configuration of distributed structures with ET 200M; this results in a very cost-efficient spare-parts maintenance.

Powerful, flexible networking Interfaces that are directly integrated in the CPUs permit the configuration of a powerful communication landscape that employs standard bus technologies, e.g. for HMI and programming device functions. Sufficient connectivity is provided for numerous HMI devices. A routing function enables a programming device to be connected at any point in the network and to address all network nodes.

CPU Spectrum :-

For setting up a programmable controller system, the user can choose from a graded spectrum of CPUs, from the starter model to the high-performance CPU. The CPUs enable short machine cycles thanks to their high processing speed. The narrow module width permits compact controller configurations and small control cabinet dimensions.

The so-called standard CPUs have a width of only 40 mm and are also available in two fail-safe designs.

A variety of compact CPUs with a width of 80 or 120 mm featuring additional integrated I/Os and technological functions are also available. This onboard I/O (digital/analog) and the technological functions, such as for counting, positioning and closed-loop control may save you from investing in additional modules.

The range is rounded off by a special technology CPU with powerful process functions.

| Design | CPU | Integrated Interfaces | Integrated I/O | Integrated technological functions | Technical specifications see page |

|---|---|---|---|---|---|

| Standard CPUs | CPU 312 | MPI | - | - | 6 |

| CPU 314 | MPI | - | - | 6 | |

| CPU 315-2-DP | DP, MPI | - | - | 6 | |

| CPU 317-2 DP | &DP, DP/MPI | - | - | 6 | |

| CPU 318-2 DP | DP, DP/MPI | - | - | 7 | |

| Fail-safe CPUs | CPU 315F-2 DP | DP, MPI | - | Fail-safety | 7 |

| CPU 317F-2 DP | DP, DP/MPI | - | Fail-safety | 7 | |

| &Compact CPUs | CPU 312C | MPI | Digital | Counting | 8 |

| CPU 313C | MPI | Digital, analog | Counting | 8 | |

| CPU 313C-2 PtP | PtP, MPI | Digital | Counting | 8 | |

| CPU 313C-2 DP | DP, MPI | Digital | Counting | 8 | |

| CPU 314C-2 PtP | PtP, MPI | Digital, analog | Counting Positioning |

9 | |

| CPU 314C-2 DP | DP, MPI | Digital, analog | Counting Positioning |

9 | |

| Technology | CPU 317T-2 DP | &DP, DP/MPI | Digital | Synchronism Travel to fixed stop Pring mark control Cam switching Controlled positioning |

9 |

Fail-safe with S7-300F :-

Fail-safe systems are used where the highest safety standards for personnel. machines and the environment must be guaranteed, i.e. accidents and damage as the result of an error must be avoided at all costs.

An additional SIMATIC fail-safe controller is now available with the S7-300F especially for safety oriented and simultaneously distributed applications in the production industry.

The predominant feature of the S7-300F is the combination of standard plant automation and safety engineering in a single system. This means that not only "normal" communication but also safety-oriented communication (using the PROFlsafe-Profile) with PROFIBU5 DP between central controller and I/O takes place - intrinsic "normal" communication is not required. This fusion of standard and safety automation considerably reduces the expenditure for configuring and designing modern safety-oriented plants.

The S7-300F achieves the safety-oriented functions through an F-CPU as well as a fail-safe modules, which can be used in the S7-300 as well as in the ET 200M and ET 200S distributed I/O systems. A special library is available from the German Technical Inspectorate (TUV) providing certified programming examples. The programming takes place with the standard LAD and FBD programming languages.

Fail-safe motor starters connected to ET 200S are available as an ideal supplement to the S7-300F.

Programming with STEP 7 and Engineering Tools

The S7-300 is programmed with the basic software STEP 7 or STEP 7 Lite. This enables the performance capa- bility of the S7-300 to be used in a simple, user-friendly manner. Both contain functions for all phases of an automation project - from configuring to commissioning, testing and servicing.

STEP 7 Lite

The cost-efficient software STEP 7 Lite is available to achieve stand-alone applications with the SIMATIC S7-300.

STEP 7 Lite is characterized by very fast entry into programming and simple project handling.

Additional SIMATIC software packages, such as Engineering Tools, cannot be used for simulation. Programs which were generated with 5TEP 7-Lite, can also be processed using STEP 7.

STEP 7

STEP 7 is used for, among other things, larger or more complex applications, with which, e.g. programming with high-level languages or graphic concept languages (see Engineering Tools) takes place or the use of function or communications modules is required.

STEP 7 enables the use of additional SIMATIC software packages, for instance Engineering Tools.

Engineering Tools

Engineering Tools open additional possibilities to program automation solutions in a user-friendly, task oriented manner. The following tools are available for programming:

S7-SCL

(Structured Control Language), the high-level language based on PASCAL for programming SIMATIC S7/C7 controllers

S7-GRAPH

for graphic configuration of sequential controls for SIMATIC S7/C7

S7-HiGraph®

for graphic description of sequential or asynchronous processes with state graphs for SIMATIC S7/C7

CFC

(Continuous Function Chart), the technological plan for graphic interconnection of complex functions for SIMATIC S7

Distributed Safety

Software package for generating safety- related programs in LAD and FBD, including F library with programming examples

The use of Engineering Tools is advantageous above all for larger, more complex applications and correspondingly greater CPUs.

CPUs/Engineering Tools