Rubber Diaphragms

OVERVIEW

KURWA RUBBER is a leading manufacturer of high performance Rubber Diaphragms. Our reputation for high performance and quality has been built on our ability to provide our valued customers with designing, engineering and manufacturing solutions to meet their most demanding applications. KURWA maintains a modern manufacturing facility having Kneader, Mixing Mill, compression moulding machineries along with technically-oriented work force to meet our clients’ critical specifications and tolerances.

The fundamental of Rubber Diaphragm is to prevent unwarranted contact between different medias (e.g. Gas and liquids) and also be flexible enough to create dynamics during flow controls. The Tensile and elongation of the Rubber allows it to control and withstand various pressures during operation and working.

We have over forty-five years’ experience specializing in the manufacturing of Rubber Diaphragms, including reinforced and unreinforced flexible rubber diaphragms. All our Diaphragms are manufactured under stringent quality control to ensure zero rejection and longevity of diaphragm life cycle.

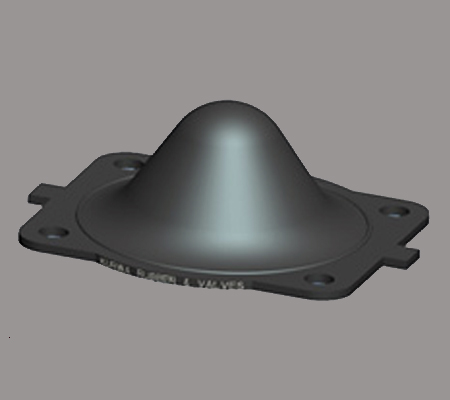

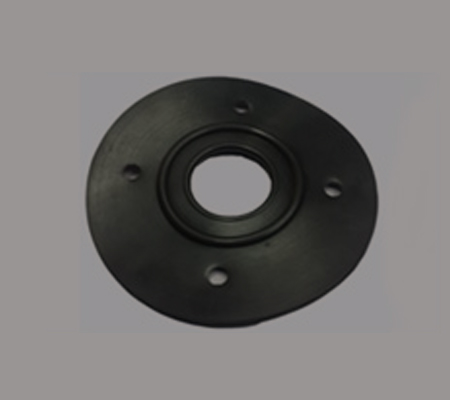

TYPE-A WEIR TYPE DIAPHRAGMS

KURWA offer High Performance Spare Rubber Diaphragms suitable for Saunders’ Pattern Type-A weir type Diaphragm Valves and other identical Indian Valves of leading makes i.e. Chemflo, Uniflo, KIPflo, Nova, Chemech, Novel Labline, Acme etc. in all grades of Synthetic Rubbers i.e. Chloroprene (Neoprene), NBR (Nitrile), EPDM, Butyl, Hypalon, Silicone, Viton & PTFE Lined. The Diaphragms can have Cotton/Nylon/Polyester/ Aramid/Kevlar/Wire-mesh type reinforcements and screw type Brass connection studs.

| STANDARD FEATURES | |

|---|---|

| SIZE RANGE (SQUARE) | 1/4” (6MM) NB TO 3” (80MM) NB – SQUARE SHAPED |

| SIZE RANGE (ROUND) | 4” (100MM) NB TO 14” (350MM) NB – ROUND SHAPED |

| WORKING PRESSURE | UPTO 10 KG/CM2 |

| TEST PRESSURE | UPTO 14 KG/CM2 |

| BURSTING PRESSURE | UPTO 24 KG/CM2 |

| AVG. OPEREATING CYCLES | 10,000 + |

OTHER FEATURES:

- All our Diaphragms are also available in reverse (close type) shape

- Diaphragms with 0.5mm PTFE (Teflon) Lining also available from 6mm to 150mm

- PTFE (Teflon) Diaphragms Pin & screw type with Rubber Pad available from 15mm to 200mmNB

- Diaphragms for Higher Pressures and vacuum services are also manufactured

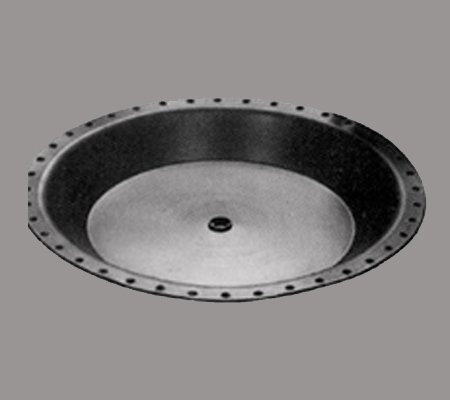

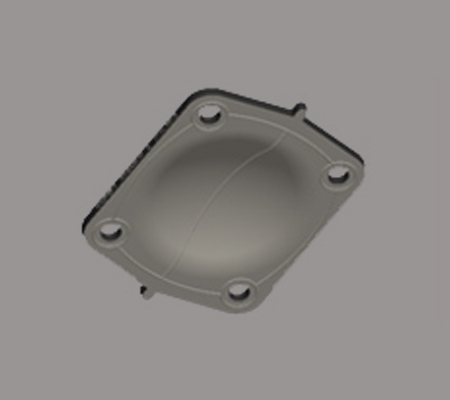

TYPE-KB STRAIGHT THROUGH TYPE

KURWA also offer Spare Rubber Diaphragms suitable for Saunders’ Pattern Type-KB straight through type Valves and other identical Indian Valves of leading makes i.e. Chemflo, Uniflo, KIPflo, Nova, Novel, Labline, Acme etc. in all grades of Synthetic Rubbers i.e. Chloroprene (Neoprene), NBR (Nitrile), EPDM, Butyl, Hypalon, Silicone & Viton. The Diaphragms have Cotton/Nylon/Polyester Fabric reinforcements and screw type MS connecting studs.

| STANDARD FEATURES | |

|---|---|

| SIZE RANGE (SQUARE) | 1” (25MM) NB TO 3” (80MM) NB – SQUARE SHAPED |

| SIZE RANGE (ROUND) | 4” (100MM) NB TO 8” (20MM) NB – ROUND SHAPED |

| WORKING PRESSURE | UPTO 8 KG/CM2 |

| TEST PRESSURE | UPTO 12 KG/CM2 |

| BURSTING PRESSURE | UPTO 18 KG/CM2 |

| AVG. OPEREATING CYCLES | 7,000 + |

| OTHER FEATURE | These Diaphragms are also available in reverse (Open type) shape |

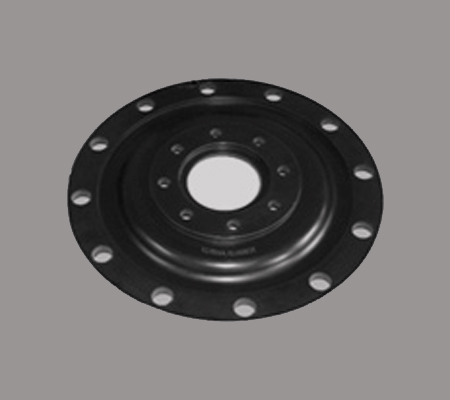

DIAPHRAGMS FOR PUMPS & ACTUATORS

KURWA RUBBER offer Rubber moulded Diaphragms, Rubber Membranes, Rolling Diaphragms, Rubber Die Cut Diaphragms with various types of reinforcement in all grades of Synthetic rubbers.

Our Diaphragms are suitable for -

- Slurry Pumps (ODS, Durco, Darco etc)

- Dosing Pumps (Prominent, Price etc)

- Metering Pumps

- Double Diaphragm operated High Pressure Pumps

- Actuators & Control Valves (Saunders™, Fischer, Xomox, Limotorque, Phoenix, Dezurick, IL, RK, Mascot, Samson etc.)

- Solenoid Valves

- Pulse Valves

- Gas regulators

- Angle Valves

- Brine Filter Valves

- Dust Collectors

- Spray Pumps

- Compressors etc.

Our speciality is to design, develop, prototype Rubber Diaphragms as per your specific requirements/service conditions.

Grades of Rubber used for different applications are Chloroprene (Neoprene), NBR (Nitrile), EPDM, Butyl, Hypalon, Silicone & Viton. These Diaphragms are suitably reinforced as per client’s service and requirement with Cotton Canvas, Nylon Fibre, Polyester, Metal Mesh, Glass Fibre, Tyre cord etc.

The Grades of Rubber are offered in respect to various services i.e. Hot Water, Steam, Low permeation gases, Ozone resistance, Oil and fuel resistance, Cryogenic applications etc. Please refer our Chemical service resistance chart as well as our general-purpose polymer chart for guidance.

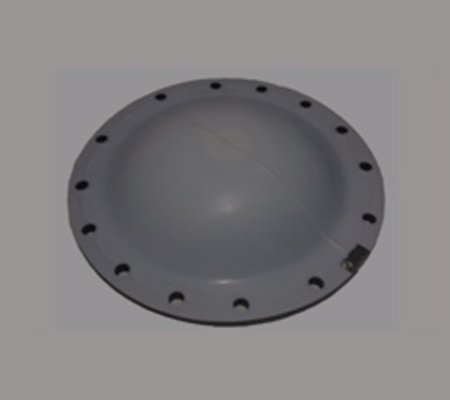

PTFE DIAPHRAGMS

Polytetrafluoroethylene-PTFE (Teflon) is an engineering thermoplastic resin that is practically resistant to all fluids. Of all our diaphragm materials, it is the most chemically resistant., PTFE can be used with media reaching very high temperatures up to 300° C. PTFE is popularly known as Teflon which is a Tradename of Dupont.

We specialise in PTFE lined Rubber Diaphragms (0.25mm, 0.5mm, 1.00mm lining thickness) as well as Pure PTFE Rigid (upto 3mm thickness) Diaphragms for all kind of Valves, pumps and actuators used in critical corrosive applications. The Rubber used with PTFE Linings are Neoprene, EPDM, Butyl & Hypalon.

Our PTFE Lined Diaphragms are made from size ranging from 12mm to 600mm Diameter in various shapes as per clients’ requirement. Our Diaphragms have been tested upto 6kg/cm2 and operated upto a 1000 cycles. These diaphragms are not suitable for vacuum service and high pressures.

We design, develop, prototype PTFE Diaphragms as per your requirements/service conditions.

Benefits of this material:

- Extremely chemically resistant

- Extremely heat resistant

- Extremely steam resistant

- Lowest coefficient of friction

- Partially Flexible

- Non-toxic

- Odourless & tasteless

- Can be sterilized

- Steam-proof

- FDA approved for food applications

Our speciality is to design, develop, prototype Rubber Diaphragms as per your specific requirements/service conditions.

Grades of Rubber used for different applications are Chloroprene (Neoprene), NBR (Nitrile), EPDM, Butyl, Hypalon, Silicone & Viton. These Diaphragms are suitably reinforced as per client’s service and requirement with Cotton Canvas, Nylon Fibre, Polyester, Metal Mesh, Glass Fibre, Tyre cord etc.

The Grades of Rubber are offered in respect to various services i.e. Hot Water, Steam, Low permeation gases, Ozone resistance, Oil and fuel resistance, Cryogenic applications etc. Please refer our Chemical service resistance chart as well as our general-purpose polymer chart for guidance.