Phone No. : +91-982 0373 895

Email id : kavita.kamble@paladinchemicals.com

Phone No. : +91-982 0373 895

Email id : kavita.kamble@paladinchemicals.com

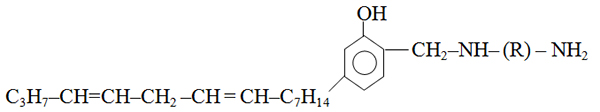

Phenalkamine PPA - 7062 is Mannich base, a reaction product of distilled cashew nutshell liquid & polyamine. It is an epoxy adduct of phenalkamine in solution form.

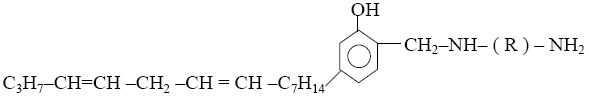

Chemical Structure :

Chemical Structure :

Features:

Applications :

Curing Properties :

| Formulation : | |

| Liquid epoxy resin (EEW-190) | 100 |

| Paladin PPA - 7062 | 100 |

| Optimum curing schedule 7 days at 25° C | |

| Gel time (100g @ 25° C)mixing | 80 - 100 min |

B.K Drying Recorder, set time, (200 microns) 8 mil

(Liquid Epoxy resin EEW - 190)

Typical Properties :

Sr. No. |

Property | Unit | Specification |

| 1 | Appearance | Visual | Orange Brown liquid |

| 2 | Colour | Gardner | 16 max |

| 3 | Amine Value | mg KOH / g | 160 – 200 |

| 4 | N.V.M. (1 hr @105° C) | % | 65 ± 2 |

| 5 | Viscosity @25° C | cPs | 1000 - 2500 |

| 6 | Density @25° C | gm / cm3 | 0.95 - 0.97 |

| 7 | Flash point (Closed cup) | °C / °F | 32 / 89.6 |

| 8 | AHEW | g / eq. | 180 |

| 9 | Recommended PHR (EEW –190) | ---- | 100 |

| @ 25° C | 3 - 4 hrs |

| @ 5° C | 9 - 12 hrs |

| @ 0° C | 16 - 18 hrs |

Storage & Stability :

Hardener PPA - 7062 should be stored in a cool dry place at 18 - 25° C in the sealed containers to achieve shelf life of minimum one year. Product can react with moisture & carbon dioxide in the air. This may result in increased viscosity & reduced activity.

Handling Precaution :

May be harmful if ingested or absorbed through the skin & can cause sensitization. Will cause severe inflammation in contact with eye & skin. Wash thoroughly after handling. Adequate ventilation is essential during application. Containers should be tightly closed when not in use or during transportation. Do not inhale mist or vapours. It is recommended to use gloves, safety glasses & protective clothing for safe handling.

First AID :

In case of

Inhalation : Remove to fresh air & give oxygen if breathing is difficult

Ingestion : Give plenty of water. Do not induce vomiting. Contact a physician

Contact with Eyes : Flush eyes with plenty of clean water for at least 15 minutes

Contact with skin : Immediately wash with mild soap & water

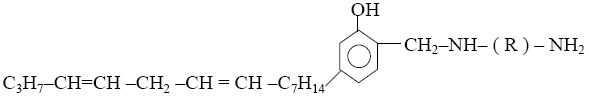

Phenalkamine PPA - 7562 is Mannich base. It is an epoxy adduct of Phenalkamine in a solution form. Phenalkamine systems based on distilled CNSL show intense yellowing during exterior exposure. They also, have colour value very high on Gardner scale. PPA - 7562 is Phenalkamine developed to improve yellowing factor, as well as to assist formulator to develop light shades, in epoxy Phenalkamine systems.

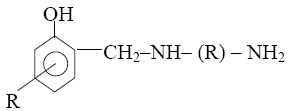

Chemical Structure :

Chemical Structure :

Features :

Applications :

Curing Properties :

| Formulation : | |

| Liquid epoxy resin (EEW –190 ) | 100 |

| PPA – 7562 | 100 |

| Optimum curing schedule 7 days at 25° C | |

| Gel time 100g@25° C | 75 - 85 |

B.K Drying Recorder, set time, (200 microns) 8 mil

(Liquid Epoxy resin EEW - 190)

Typical Properties :

Sr. No. |

Property | Unit | Specification |

| 1 | Appearance | Visual | Pale Yellow Viscous Liquid |

| 2 | Colour | Gardner | 11 Max |

| 3 | Amine Value | mgKOH/g | 180 - 220 |

| 4 | N.V.M. (1 hr @105° C) | % | 65 ± 2 |

| 5 | Viscosity @25° C | cPs | 500 - 3000 |

| 6 | Density @25° C | gm/cm3 | 0.97 - 1.00 |

| 7 | Flash Point (Closed cup) | °C / °F | 31 / 87.8 |

| 8 | AHEW | g/eg. | 180 |

| 9 | Recommended PHR (EEW–190) | ---- | 100 |

| @ 25° C | 3 - 4 hrs |

| @ 5° C | 9 - 12 hrs |

| @ 0° C | 17 - 18 |

Storage & Stability :

Hardener PPA - 7562 should be stored in a cool dry place at 18 - 25° C in the sealed containers to achieve shelf life of minimum one year. Product can react with moisture & carbon dioxide in the air. This may result in increased viscosity & reduced activity.

Handling & Precaution :

May be harmful if ingested or absorbed through the skin & can cause sensitization. Will cause severe inflammation in contact with eye & skin. Wash thoroughly after handling. Adequate ventilation is essential during application. Containers should be tightly closed when not in use or during transportation. Do not inhale mist or vapours. It is recommended to use gloves, safety glasses & protective clothing for safe handling.

First AID :

In case of

Inhalation : Remove to fresh air & give oxygen if breathing is difficult

Ingestion : Give plenty of water. Do not induce vomiting. Contact a physician

Contact with Eyes : Flush eyes with plenty of clean water for at least 15 minutes

Contact with skin : Immediately wash with mild soap & water

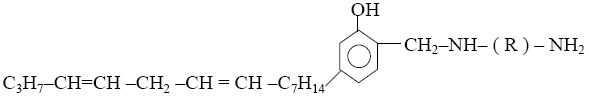

Phenalkamine PPA - 7368 is a Mannich base, a reaction product of distilled cashew nutshell liquid & polyamine. It is an epoxy adduct of phenalkamine.

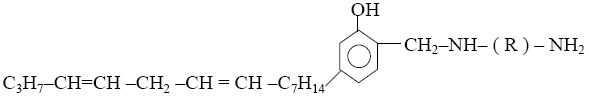

Chemical Structure :

Chemical Structure :

Features :

Applications :

Curing Properties :

| Formulation : | |

| Liquid epoxy resin (EEW -190) | 100 |

| Paladin PPA - 7368 | 100 |

| Optimum curing schedule 7 days at 25° C | |

| Gel time ( 100g @ 25° C ) mixing | 60 - 80min |

B.K Drying Recorder, set time, (200 microns) 8 mil

(Liquid Epoxy resin EEW - 190)

Typical Properties :

Sr. No. |

Property | Unit | Specification |

| 1 | Appearance | Visual | Orange Brown Liquid |

| 2 | Colour | Gardner | 16 max |

| 3 | Amine Value | mg KOH / g | 170 - 190 |

| 4 | N.V.M. (1 hr @105° C) | % | 63 ± 1.5 |

| 5 | Viscosity @ 25° C | cPs | 700 - 2500 |

| 6 | Density @ 25° C | g / cm3 | 0.97 - 0.99 |

| 7 | Flash point (Closed cup) | °C / °F | 31 / 87.8 |

| 8 | AHEW | g / eq. | 190 |

| 9 | Recommended PHR (EEW –190) | -- | 100 |

| @ 25° C | 1 - 2 hrs |

| @ 5° C | 8 - 10 hrs |

| @ 0° C | -- |

Storage & Stability :

Hardener PPA - 7368 should be stored in a cool dry place at 18 - 25° C in the sealed containers to achieve shelf life of minimum one year. Product can react with moisture & carbon dioxide in the air. This may result in increased viscosity & reduced activity.

Handling & Precaution :

May be harmful if ingested or absorbed through the skin & can cause sensitization. Will cause severe inflammation in contact with eye & skin. Wash thoroughly after handling. Adequate ventilation is essential during application. Containers should be tightly closed when not in use or during transportation. Do not inhale mist or vapours. It is recommended to use gloves, safety glasses & protective clothing for safe handling.

First AID :

In case of

Inhalation : Remove to fresh air & give oxygen if breathing is difficult

Ingestion : Give plenty of water. Do not induce vomiting. Contact a physician

Contact with Eyes : Flush eyes with plenty of clean water for at least 15 minutes

Contact with skin : Immediately wash with mild soap & water

Phenalkamine PPA- 7351 X 70 is Mannich base. A reaction product of distilled cashew nutshell liquid & polyamine. It is an Epoxy Adduct solution of phenalkamine, based on suitable polyamine.

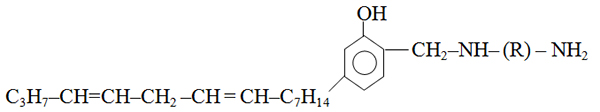

Chemical Structure :

Chemical Structure :

Features :

Applications :

Curing Properties :

| Formulation : | |

| Liquid Epoxy Resin (EEW-190) | 100 |

| PPA – 7351 X 70 | 100 |

| Optimum Curing Schedule 7 days at 25° C | |

| Gel Time (100g@25° C) Mixing | 30 - 40 min |

B.K Drying Recorder, set time, ( 200 microns ) 8 mil

(Liquid Epoxy Resin EEW-190)

Typical Properties :

Sr. No. |

Property | Unit | Specification |

| 1 | Appearance | Visual | Reddish brown viscous liquid |

| 2 | Colour | Gardner | 17 Max |

| 3 | Amine Value | mg KOH / g | 180 - 210 |

| 4 | N.V.M. (1 hr @105° C) | % | 67 - 71 |

| 5 | Viscosity @25° C | cPs | 1500 - 3000 |

| 6 | Density @25° C | gm / cm3 | 0.99 - 1.01 |

| 7 | Flash point (Closed Cup) | °C / °F | 33 / 91.40 |

| 8 | AHEW | g / eq. | 291(70%) / 204(100%) |

| 9 | Recommended PHR (EEW -190) | ---- | 153 |

| @ 25° C | 1 - 2 hrs |

| @ 5° C | 6 - 8 hrs |

| @ 0° C | 10 - 12 |

Storage & Stability :

Hardener PPA - 7351 X 70 should be stored in a cool dry place at 18 - 25°c in the sealed containers to achieve shelf life of minimum one year. Product can react with moisture & carbon dioxide in the air. This may result in increased viscosity & reduced activity.

Handling & Precaution :

May be harmful if ingested or absorbed through the skin & can cause sensitization. Will cause severe inflammation in contact with eye & skin. Wash thoroughly after handling. Adequate ventilation is essential during application. Containers should be tightly closed when not in use or during transportation. Do not inhale mist or vapours. It is recommended to use gloves, safety glasses & protective clothing for safe handling.

First AID :

In case of

Inhalation : Remove to fresh air & give oxygen if breathing is difficult

Ingestion : Give plenty of water. Do not induce vomiting. Contact a physician

Contact with Eyes : Flush eyes with plenty of clean water for at least 15 minutes

Contact with skin : Immediately wash with mild soap & water

Phenalkamine PPA – 7077 X 80 is Mannich base, a reaction product of distilled cashew nutshell liquid, phenol & polyamine. It is a low viscosity, fast drying curing agent. In general, it shows ability to resist moisture, while curing & exhibits rapid cure, even at low temperatures, similar to other phenalkamines. Epoxy systems based on PPA – 7077 X 80 shows excellent adhesion on difficult surfaces (e.g. galvanize, zinc rich epoxy, zinc silicate etc.)

Chemical Structure :

Chemical Structure :

Features :

Applications :

Curing Properties :

| Formulation : | |

| Liquid Epoxy Resin (EEW - 190) | 100 |

| Paladin PPA – 7077 X 80 | 100 |

| Optimum Curing Schedule 7 days at 25° C in Minutes | |

| Gel Time ( 100g @ 25° C ) Mixing | 50 min |

B.K Drying Recorder, set time, ( 200 microns ) 8 mil

(Liquid Epoxy Resin EEW - 190)

Typical Properties :

Sr. No. |

Property | Unit | Specification |

| 1 | Appearance | Visual | Light Brown Viscous Liquid |

| 2 | Colour | Gardner | 16 max |

| 3 | N.V.M | % | 78 – 82 |

| 4 | Amine Value | mg KOH / g | 200 – 240 |

| 5 | Viscosity @25° C | cPs | 1000 – 3000 |

| 6 | Density @25° C | -- | 0.97 – 0.99 |

| 7 | Flash Point (Closed Cup) | °C / °F | 32 / 90 |

| 8 | AHEW | g / eq. | 190 |

| 9 | Recommended PHR (Liquid Epoxy Resin EEW -190) | ---- | 100 |

| @ 25° C | 2 – 3 hrs |

| @ 5° C | 9 – 11 hrs |

Storage & Stability :

Hardener PPA – 7077 X 80 should be stored in a cool dry place at 18 - 25 ° C in the sealed containers to achieve shelf life of minimum one year. Product can react with moisture & carbon dioxide in the air. This may result in increased viscosity & reduced activity.

Handling & Precaution :

May be harmful if ingested or absorbed through the skin & can cause sensitization. Will cause severe inflammation in contact with eye & skin. Wash thoroughly after handling. Adequate ventilation is essential during application. Containers should be tightly closed when not in use or during transportation. Do not inhale mist or vapors. It is recommended to use gloves, safety glasses & protective clothing for safe handling.

First AID :

In case of

Inhalation : Remove to fresh air & give oxygen if breathing is difficult

Ingestion : Give plenty of water. Do not induce vomiting. Contact a physician

Contact with Eyes : Flush eyes with plenty of clean water for at least 15 minutes

Contact with skin : Immediately wash with mild soap & water.

Phenalkamine systems based on distilled CNSL shows intense yellowing during exterior exposure & as such has colour value very high on gardner scale. PPA - 7090 is phenalkamine developed to improve the yellowing factor, as well as to assist formulator to develop the lighter shades in epoxy phenalkamine systems.

Chemical Structure :

Chemical Structure :

Features :

Applications :

Curing Properties :

| Formulation : | |

| Liquid epoxy resin ( EEW-190 ) | 100 |

| Paladin PPA - 7090 | 100 |

| Optimum curing schedule 7 days at 25° C | |

| Gel time (100g @ 25° C) mixing | 30 - 40 min |

B.K Drying Recorder, set time, (200 microns) 8 mil

(Liquid Epoxy resin EEW - 190)

Typical Properties :

Sr. No. |

Property | Unit | Typical properties |

| 1 | Appearance | Visual | Pale viscous liquid |

| 2 | Colour | Gardner | 10 Max |

| 3 | N.V.M. (1 hr @105° C) | % | Solvent free |

| 4 | Amine Value | MgKOH / g | 240 – 280 |

| 5 | Viscosity @25° C | cPs | 75000 - 150000 |

| 6 | Density @25° C | Kg / ltr | 0.98 - 1.00 |

| 7 | Flash point | °C / °F | 205 / 401 |

| 8 | AHEW (100 % solids) | g / eq. | 190 |

| 9 | PHR (Liquid epoxy resin - EEW=190) | -- | 100 |

| @ 25° C | 3 - 5 hrs |

| @ 5° C | 20 - 24 hrs |

| @ 0° C | - |

Storage & Stability :

Hardener PPA - 7090 should be stored in a cool dry place at 18 - 25° C in the sealed containers to achieve shelf life of minimum one year. Product can react with moisture & carbon dioxide in the air. This may result in increased viscosity & reduce its activity.

Handling & Precaution :

May be harmful if ingested or absorbed through the skin & can cause sensitization. Will cause severe inflammation in contact with eye & skin. Wash thoroughly after handling. Adequate ventilation is essential during application. Containers should be tightly closed when not in use or during transportation. Do not inhale mist or vapours. It is recommended to use gloves, safety glasses & protective clothing for safe handling.

First AID :

In case of

Inhalation : Remove to fresh air & give oxygen if breathing is difficult

Ingestion : Give plenty of water. Do not induce vomiting. Contact a physician

Contact with Eyes : Flush eyes with plenty of clean water for at least 15 minutes

Contact with skin : Immediately wash with mild soap & water.

Phenalkamine PPA - 7108 is Mannich base, a reaction product of distilled cashew nutshell liquid & polyamine. It is epoxy adduct of Phenalkamine in solution form.

Chemical Structure :

Chemical Structure :

Features :

Applications :

Curing Properties :

| Formulation : | |

| Liquid epoxy resin (EEW –190) | 100 |

| Paladin PPA - 7108 | 66 |

| Optimum curing schedule 7 days at 25° C | |

| Gel time 100g@25° C mixing | 50 - 60 min |

B.K Drying Recorder, set time, ( 200 microns ) 8 mil

( Liquid Epoxy resin EEW - 190 )

Typical Properties :

Sr. No. |

Property | Unit | Specification |

| 1 | Appearance | Visual | Orange Brown liquid |

| 2 | Colour | Gardner | 14 max |

| 3 | Amine Value | mgKOH/g | 320 – 370 |

| 4 | N.V.M. (1 hr @105° C) | % | 75 ± 2 |

| 5 | Viscosity @25° C | cPs | 500-3000 |

| 6 | Density @25° C | gm/cm3 | 0.95 0.97 |

| 7 | Flash Point (Closed cup) | °C / °F | 35 / 95 |

| 8 | AHEW | g/eg. | 125 |

| 9 | Recommended PHR (EEW–190) | ---- | 66 |

| @ 25° C | 3 - 5 hrs |

| @ 5° C | 15 - 18 hrs |

| @ 0° C | -- |

Storage & Stability :

Hardener PPA - 7108 should be stored in a cool dry place at 18 - 25° C in the sealed containers to achieve shelf life of minimum one year. Product can react with moisture & carbon dioxide in the air. This may result in increased viscosity & reduced activity.

Handling & Precaution :

May be harmful if ingested or absorbed through the skin & can cause sensitization. Will cause severe inflammation in contact with eye & skin. Wash thoroughly after handling. Adequate ventilation is essential during application. Containers should be tightly closed when not in use or during transportation. Do not inhale mist or vapours. It is recommended to use gloves, safety glasses & protective clothing for safe handling.

First AID :

In case of

Inhalation : Remove to fresh air & give oxygen if breathing is difficult

Ingestion : Give plenty of water. Do not induce vomiting. Contact a physician

Contact with Eyes : Flush eyes with plenty of clean water for at least 15 minutes

Contact with skin : Immediately wash with mild soap & water

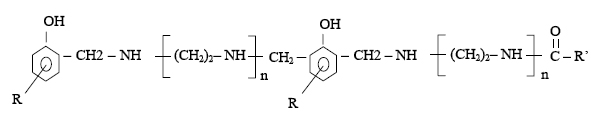

Phenalkamide PPA - 7088 is an epoxy adduct of Mannich base reaction product. It shows rapid cure with workable pot life, superior corrosion resistant properties & adhesion to damp surfaces. It has longer pot life to card phenol based Phenalkamines. It offers superior resistance to humidity, acids, alkali, water, solvents & various chemicals.

Chemical Structure :

Chemical Structure :

R = H, ALKYL, ARYL

R’ = MONOMERIC, DIMERIC OR POLYMER OF FATTY ACID

Features :

Applications :

Curing Properties :

| Formulation : | |

| Liquid epoxy resin ( EEW–190 ) | 30 |

| Paladin PPA - 7088 | 70 |

| Optimum curing schedule 7 days at 25° C | |

| Gel time (100g @ 25° C) mixing | 120 - 180 min |

B.K Drying Recorder, set time, (200 microns) 8 mil

(Liquid Epoxy resin EEW - 190)

Typical Properties :

Sr. No. |

Property | Unit | Specification |

| 1 | Appearance | Visual | Dark brown viscous liquid |

| 2 | Colour | Gardner | 16 max |

| 3 | N.V.M. (1 hr @105° C) | % | 65 ±2 |

| 4 | Amine Value | MgKOH / g | 130 - 180 |

| 5 | Viscosity @25° C | cPs | 500 - 1500 |

| 6 | Density @25° C | kg / litre | 0.96 - 0.98 |

| 7 | Flash point (Closed cup) | °C / °F | 26.5 / 80 |

| 8 | AHEW | g / eq. | 462 |

| 9 | Recommended PHR (Liquid epoxy resin –190) | ---- | 243 |

| @ 25° C | 3 - 6 hrs |

| @ 5° C | 18 - 20 hrs |

| @ 0° C | - |

Storage & Stability :

Hardener PPA-7088 should be stored in a cool dry place at 18 - 25 ° C in the sealed containers to achieve shelf life of minimum one year. Product can react with moisture & carbon dioxide in the air. This may result in increased viscosity & reduced activity.

Handling & Precaution :

May be harmful if ingested or absorbed through the skin & can cause sensitization. Will cause severe inflammation in contact with eye & skin. Wash thoroughly after handling. Adequate ventilation is essential during application. Containers should be tightly closed when not in use or during transportation. Do not inhale mist or vapors. It is recommended to use gloves, safety glasses & protective clothing for safe handling.

First AID :

In case of

Inhalation : Remove to fresh air & give oxygen if breathing is difficult

Ingestion : Give plenty of water. Do not induce vomiting. Contact a physician

Contact with Eyes : Flush eyes with plenty of clean water for at least 15 minutes

Contact with skin : Immediately wash with mild soap & water