FIRST TIME RIGHT AND ALWAYS RIGHT IS OUR PROMISE

At PCPL unsurpassed quality is the central focus in every product development procedure. Focus on quality derived from the Feasibility study has become a mantra for us. We have broken the process of quality product development in three parts – Methoding, Manufacturing, and Supplies.

To ensure optimal production efficiency we believe in getting onboard experienced and knowledgeable people with the right skill set. They are then provided with the appropriate position and required high-end equipment to commence an impeccable manufacturing cycle. Whenever we observe a gap in their skill set we bridge the gap by providing them the required training.

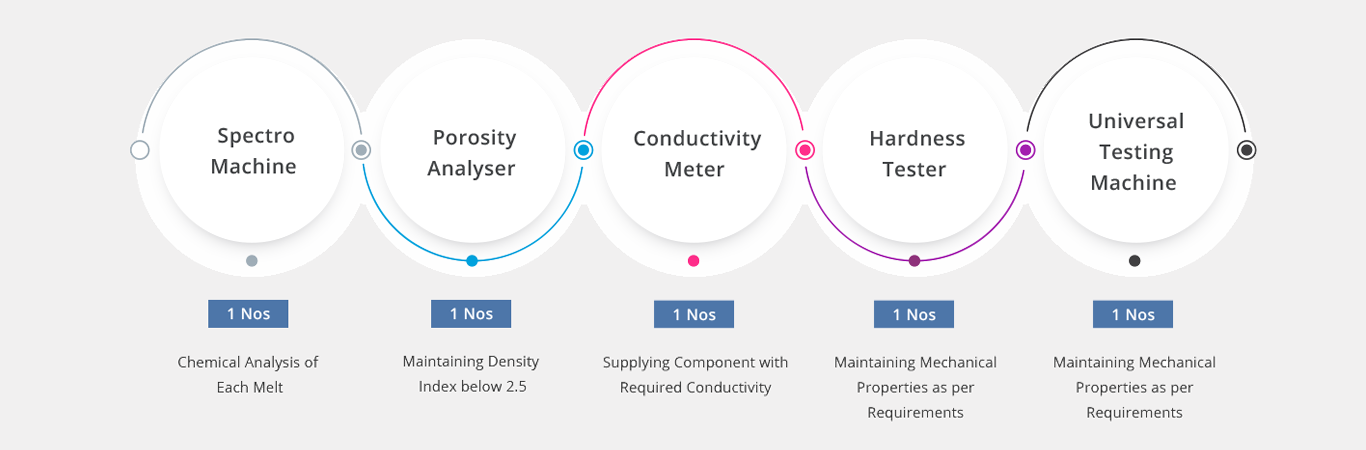

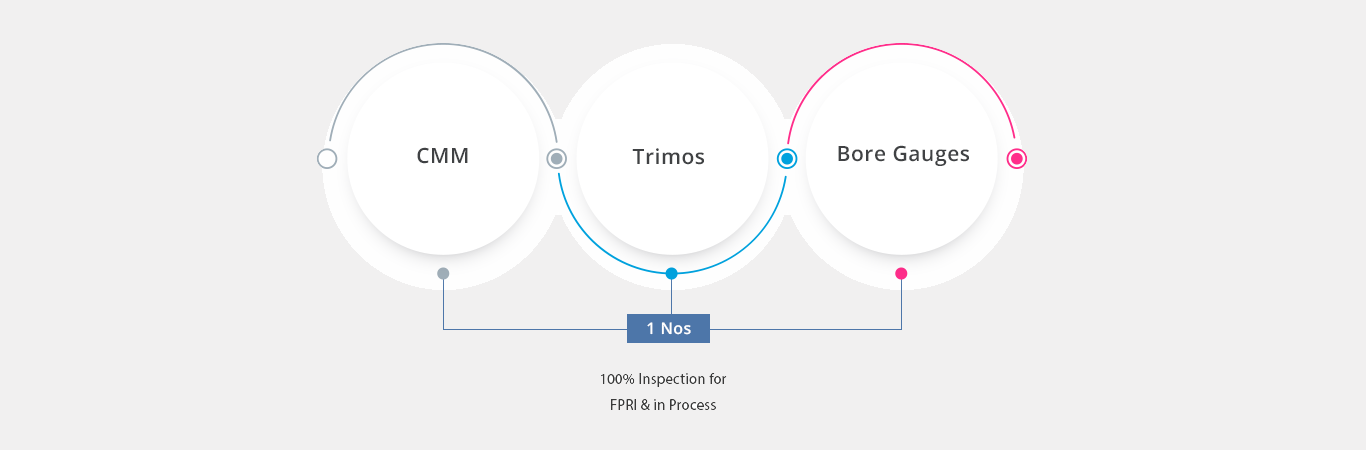

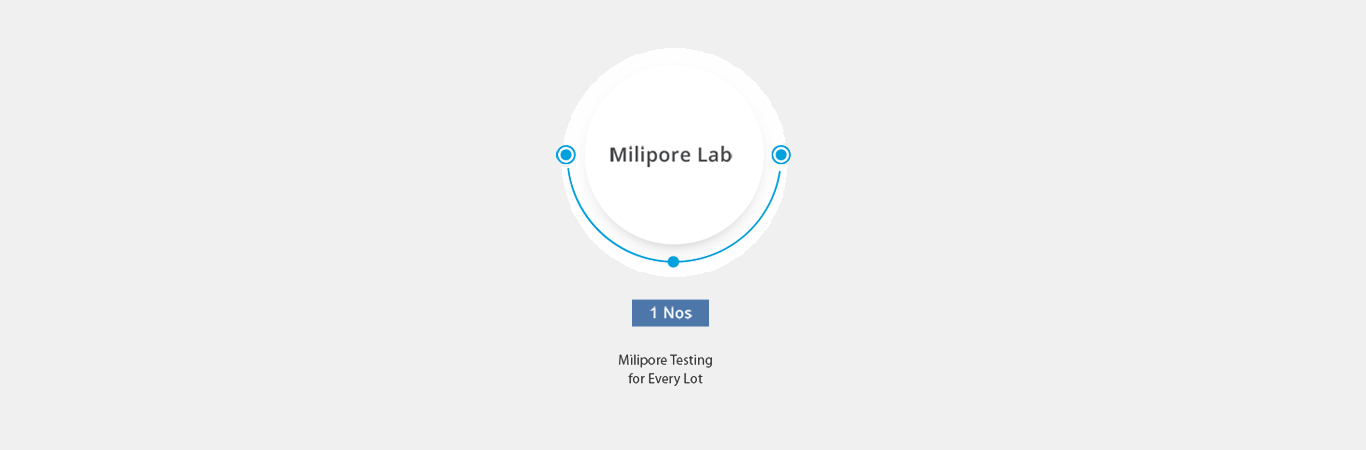

We have put into place Quality systems and Quality gates at every stage of manufacturing right from the initial incoming inspection stage to the final product delivery stage. Besides building a ‘Firewall’ we have also devised an error-free manufacturing process by employing ‘Poka-Yoke’. Furthermore, advanced manufacturing systems like:-