Products & Services

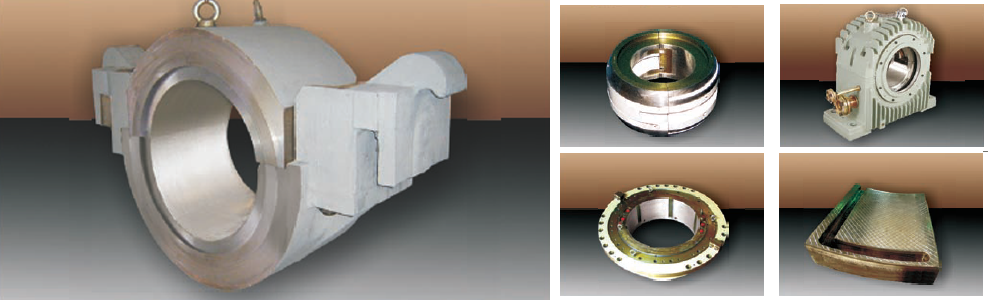

Bearings and bearing modules as per DIN-31690, DIN-31693 for use in electrical machinery, air-handling etc., are manufactured in following ranges.

- PF Type Size 9-28 Dia 80 to 300 DIN-31693

- PF Type Size 9-28 Dia 70 to 335 DIN-31690

- PF Type Size 9-28 Dia 80 to 335 DIN-31694

In addition, size 35 is manufactured in both PR and PM types. The housing can be executed in various materials such as cast iron, S. G. iron, steel, low temperature resistant steel etc. The babbit material is tin based. These bearings are inter-changeable and have many options for seals, bearings insulation, shaft location etc.

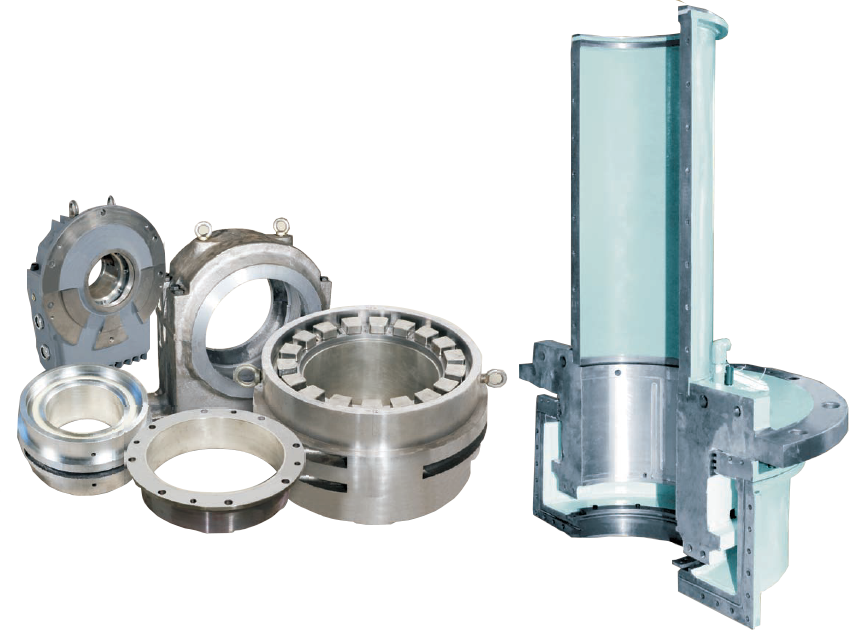

Customer Defined Bearings

Beaings and bearing assemblies as per customer's dwawings and specification can be made in small or large batch quantities. The quality assurence programme ensures, bearings of the highest quality are delivered to the customers.

The customer defined bearings include thrust pads, journal pads, profiled bearings etc. Apart form bearings, other related components, such as labyrinth seals, oil rings, oil splash rings and other components can also be supplied.

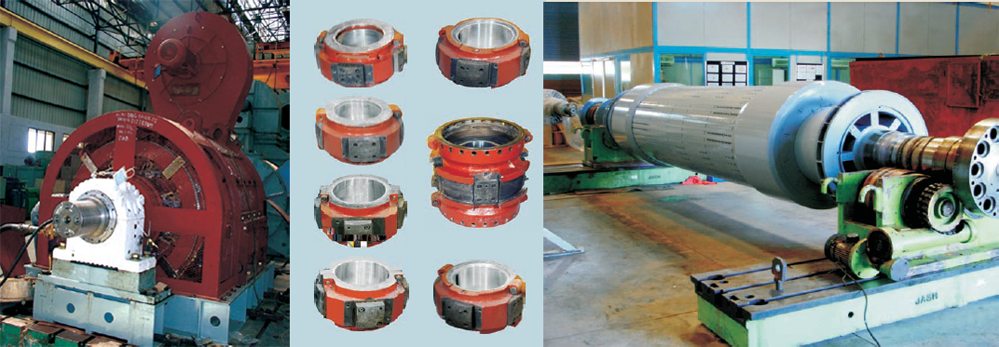

Repair, Re-engineering & Retrofit Services

The repairs, re-engineering and retrofit services from an important part of the group activities. During the last 3 decades, a number of major re-engineering and retrofit projects have been undertaken resulting in substantial savings to our customers.

Repair Services

Worn-out, old and damaged bearings re-babbited by using same or similar performance babbit metals. These are machined to the original tolerances or to customer’s requirements. The same care that goes into making new bearing is taken in repairing of old bearings to ensure a long and trouble-free operation.

Re-engineering & Retrofit Services

Based on group’s design, engineering and procurement capabilities, a comprehensive re-engineering and retrofit service is offered. The services include possible design improvements, changes in specifications, complete re-design, manufacture and trouble shooting. Cases such as worn-out, missing or partly missing bearings and bearing assemblies, very old design bearings, which are expensive to repair or non-availability of components due to discontinuation of manufacture / supply by original supplier, are some of the problem areas addressed by the retrofit services.

The design group initially studies the customer’s requirements in detail and then, in consultation with the customer, makes a technical proposal. This will include proposed re-design, selection of materials, performance calculations etc. On approval of the technical proposal, new bearings are made which will exactly suit customer’s requirements.