Plastic Moulded Components

Our organization is involved in manufacturing of quality Plastic Moulded Components. We also provide Reverse Engineering & Product design services.

Details

- CNC Machining Center (MAKINO Max65-size 650 x 400 x 400-8000 rpm)

- CNC Machining Center (HAAS VF3-size 1000 x 500 x 600-15,000 rpm)

- EDM Spark Erosion (JOMERS JM430-50 amp generator, Tank size-1060 x 600)

- EDM Spark Erosion (JOMERS JM320-50 amp generator, Tank size-830 x 500)

- Surface Grinder (ALEX-500 x 200)

- Surface Grinder (BLOHM- 750 x 500 x 600)

- Lathe (PSG make)

- Radial Drill (Batliboi-BVR5-65 dia cap)

- Inspection TRIMOS Electronic height gauge (Model V 600)

- Inhouse Die Polishing

- CAD CAM Workstation (Pro Engineer Delcam-Powermill)

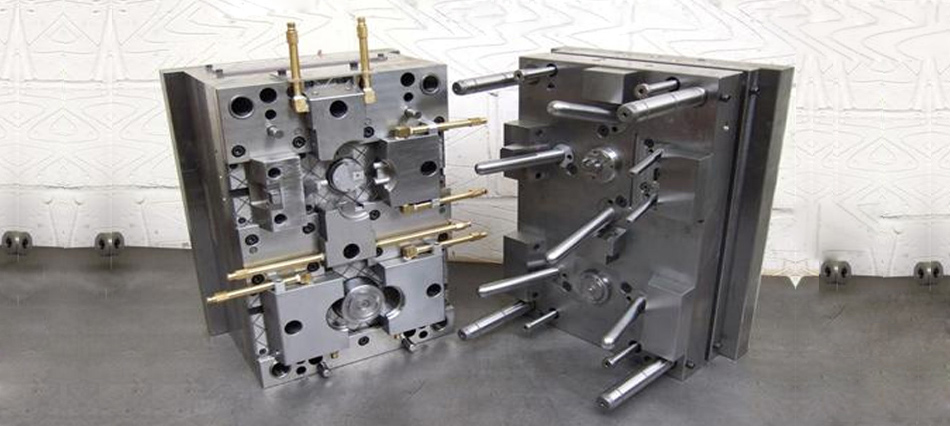

Plastic Molds

Following facilities available at Factory:

Following facilities available at Factory:

- CNC Machining Center (MAKINO Max65-size 650 x 400 x 400-8000 rpm)

- CNC Machining Center (HAAS VF3-size 1000 x 500 x 600-15,000 rpm)

- EDM Spark Erosion (JOMERS JM430-50 amp generator, Tank size-1060 x 600)

- EDM Spark Erosion (JOMERS JM320-50 amp generator, Tank size-830 x 500)

- Surface Grinder (ALEX-500 x 200)

- Surface Grinder (BLOHM- 750 x 500 x 600)

- Lathe (PSG make)

- Radial Drill (Batliboi-BVR5-65 dia cap)

- Inspection TRIMOS Electronic height gauge (Model V 600)

- Inhouse Die Polishing

- CAD CAM Workstation (Pro Engineer Delcam-Powermill)

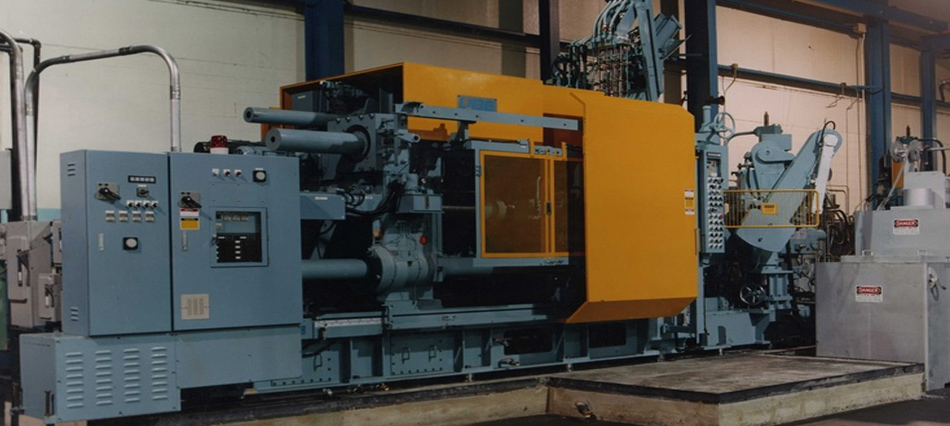

Plastic Injection Moulding

We are engaged in mnaufacturing and supplying a wide array of Plastic Injection Moulding. These Plastic Injection Moulding machines are highly effective for molding plastic in different shapes, sizes and dimensions.

We are engaged in mnaufacturing and supplying a wide array of Plastic Injection Moulding. These Plastic Injection Moulding machines are highly effective for molding plastic in different shapes, sizes and dimensions.

Following facilities available at Factory:

- CNC Machining Center (MAKINO Max65-size 650 x 400 x 400-8000 rpm)

- CNC Machining Center (HAAS VF3-size 1000 x 500 x 600-15,000 rpm)

- EDM Spark Erosion (JOMERS JM430-50 amp generator, Tank size-1060 x 600)

- EDM Spark Erosion (JOMERS JM320-50 amp generator, Tank size-830 x 500)

- Surface Grinder (ALEX-500 x 200)

- Surface Grinder (BLOHM- 750 x 500 x 600)

- Lathe (PSG make)

- Radial Drill (Batliboi-BVR5-65 dia cap)

- Inspection TRIMOS Electronic height gauge (Model V 600)

- Inhouse Die Polishing

- CAD CAM Workstation (Pro Engineer Delcam-Powermill)

Plastic Molded Components

Backed by a proficient manufacturing unit we offer our clients a wide range of Plastic Molded Components that is a manufacturing process for producing parts from both thermoplastic and thermosetting plastic materials. We have latest technology support that helps us in keeping pace with ever-changing industry demands like auto helmets, presentation products, & glaze. Our complete range is methodically tested in our quality-testing laboratory and further delivered to our respected clients extended across the sphere. Further, these are widely used for manufacturing a variety of parts.

Backed by a proficient manufacturing unit we offer our clients a wide range of Plastic Molded Components that is a manufacturing process for producing parts from both thermoplastic and thermosetting plastic materials. We have latest technology support that helps us in keeping pace with ever-changing industry demands like auto helmets, presentation products, & glaze. Our complete range is methodically tested in our quality-testing laboratory and further delivered to our respected clients extended across the sphere. Further, these are widely used for manufacturing a variety of parts.

Following facilities available at Factory:

- CNC Machining Center (MAKINO Max65-size 650 x 400 x 400-8000 rpm)

- CNC Machining Center (HAAS VF3-size 1000 x 500 x 600-15,000 rpm)

- EDM Spark Erosion (JOMERS JM430-50 amp generator, Tank size-1060 x 600)

- EDM Spark Erosion (JOMERS JM320-50 amp generator, Tank size-830 x 500)

- Surface Grinder (ALEX-500 x 200)

- Surface Grinder (BLOHM- 750 x 500 x 600)

- Lathe (PSG make)

- Radial Drill (Batliboi-BVR5-65 dia cap)

- Inspection TRIMOS Electronic height gauge (Model V 600)

- Inhouse Die Polishing

- CAD CAM Workstation (Pro Engineer Delcam-Powermill)

Engineering Plastic Molds

Following facilities available at Factory:

Following facilities available at Factory:

- CNC Machining Center (MAKINO Max65-size 650 x 400 x 400-8000 rpm)

- CNC Machining Center (HAAS VF3-size 1000 x 500 x 600-15,000 rpm)

- EDM Spark Erosion (JOMERS JM430-50 amp generator, Tank size-1060 x 600)

- EDM Spark Erosion (JOMERS JM320-50 amp generator, Tank size-830 x 500)

- Surface Grinder (ALEX-500 x 200)

- Surface Grinder (BLOHM- 750 x 500 x 600)

- Lathe (PSG make)

- Radial Drill (Batliboi-BVR5-65 dia cap)

- Inspection TRIMOS Electronic height gauge (Model V 600)

- Inhouse Die Polishing

- CAD CAM Workstation (Pro Engineer Delcam-Powermill)

Plastic Molded Components

Backed by a proficient manufacturing unit we offer our clients a wide range of Plastic Molded Components that is a manufacturing process for producing parts from both thermoplastic and thermosetting plastic materials. We have latest technology support that helps us in keeping pace with ever-changing industry demands like auto helmets, presentation products, & glaze. Our complete range is methodically tested in our quality-testing laboratory and further delivered to our respected clients extended across the sphere. Further, these are widely used for manufacturing a variety of parts.

Backed by a proficient manufacturing unit we offer our clients a wide range of Plastic Molded Components that is a manufacturing process for producing parts from both thermoplastic and thermosetting plastic materials. We have latest technology support that helps us in keeping pace with ever-changing industry demands like auto helmets, presentation products, & glaze. Our complete range is methodically tested in our quality-testing laboratory and further delivered to our respected clients extended across the sphere. Further, these are widely used for manufacturing a variety of parts.

Following facilities available at Factory:

- CNC Machining Center (MAKINO Max65-size 650 x 400 x 400-8000 rpm)

- CNC Machining Center (HAAS VF3-size 1000 x 500 x 600-15,000 rpm)

- EDM Spark Erosion (JOMERS JM430-50 amp generator, Tank size-1060 x 600)

- EDM Spark Erosion (JOMERS JM320-50 amp generator, Tank size-830 x 500)

- Surface Grinder (ALEX-500 x 200)

- Surface Grinder (BLOHM- 750 x 500 x 600)

- Lathe (PSG make)

- Radial Drill (Batliboi-BVR5-65 dia cap)

- Inspection TRIMOS Electronic height gauge (Model V 600)

- Inhouse Die Polishing

- CAD CAM Workstation (Pro Engineer Delcam-Powermill)

Injection Molded Plastic Components

Following facilities available at Factory:

Following facilities available at Factory:

- CNC Machining Center (MAKINO Max65-size 650 x 400 x 400-8000 rpm)

- CNC Machining Center (HAAS VF3-size 1000 x 500 x 600-15,000 rpm)

- EDM Spark Erosion (JOMERS JM430-50 amp generator, Tank size-1060 x 600)

- EDM Spark Erosion (JOMERS JM320-50 amp generator, Tank size-830 x 500)

- Surface Grinder (ALEX-500 x 200)

- Surface Grinder (BLOHM- 750 x 500 x 600)

- Lathe (PSG make)

- Radial Drill (Batliboi-BVR5-65 dia cap)

- Inspection TRIMOS Electronic height gauge (Model V 600)

- Inhouse Die Polishing

- CAD CAM Workstation (Pro Engineer Delcam-Powermill)