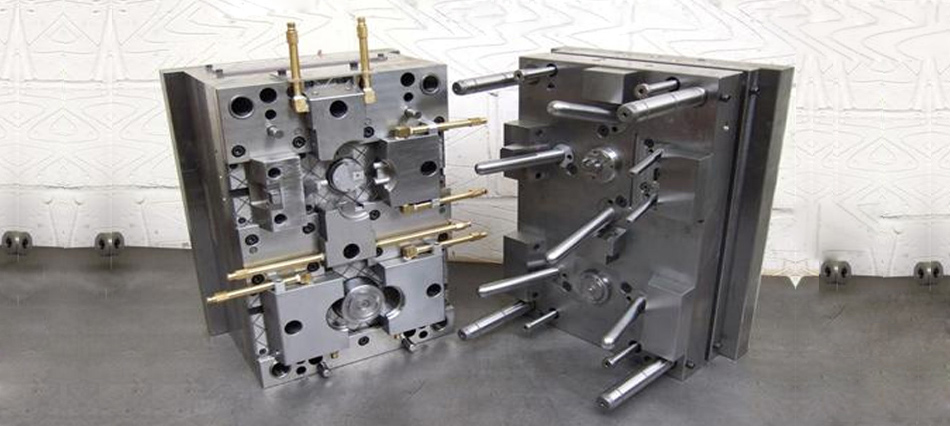

Pressure Die Casting Dies

Our organization is involved in manufacturing of quality Pressure Die Casting Dies. We also provide Reverse Engineering & Product design services.

Details:

- CNC Machining Center (MAKINO Max65-size 650 x 400 x 400-8000 rpm)

- CNC Machining Center (HAAS VF3-size 1000 x 500 x 600-15,000 rpm)

- EDM Spark Erosion (JOMERS JM430-50 amp generator, Tank size-1060 x 600)

- EDM Spark Erosion (JOMERS JM320-50 amp generator, Tank size-830 x 500)

- Surface Grinder (ALEX-500 x 200)

- Surface Grinder (BLOHM- 750 x 500 x 600)

- Lathe (PSG make)

- Radial Drill (Batliboi-BVR5-65 dia cap)

- Inspection TRIMOS Electronic height gauge (Model V 600)

- Inhouse Die Polishing

- CAD CAM Workstation (Pro Engineer Delcam-Powermill)

Pressure Die Casting Dies

.jpg) Our Pressure Die Casting Dies are made from high grade material. We undertake the process of die casting dies which are widely used in kiln industry. Our professionals are well versed with die casting process and uses latest technology to accomplish the task. Die casting is a manufacturing process for manufacturing dimensionally accurate, smooth textured surface metal parts. In the process molten metals are forced under high pressure to manufacture reusable metal dies.

Our Pressure Die Casting Dies are made from high grade material. We undertake the process of die casting dies which are widely used in kiln industry. Our professionals are well versed with die casting process and uses latest technology to accomplish the task. Die casting is a manufacturing process for manufacturing dimensionally accurate, smooth textured surface metal parts. In the process molten metals are forced under high pressure to manufacture reusable metal dies.

Following facilities available at Factory:

- CNC Machining Center (MAKINO Max65-size 650 x 400 x 400-8000 rpm)

- CNC Machining Center (HAAS VF3-size 1000 x 500 x 600-15,000 rpm)

- EDM Spark Erosion (JOMERS JM430-50 amp generator, Tank size-1060 x 600)

- EDM Spark Erosion (JOMERS JM320-50 amp generator, Tank size-830 x 500)

- Surface Grinder (ALEX-500 x 200)

- Surface Grinder (BLOHM- 750 x 500 x 600)

- Lathe (PSG make)

- Radial Drill (Batliboi-BVR5-65 dia cap)

- Inspection TRIMOS Electronic height gauge (Model V 600)

- Inhouse Die Polishing

- CAD CAM Workstation (Pro Engineer Delcam-Powermill)

Die Casting Dies

We are offering a wide range of pressure Die Casting Dies, which is used in various industries for the production of different machine parts. These components are known for offering high performance, efficiency and durability.

We are offering a wide range of pressure Die Casting Dies, which is used in various industries for the production of different machine parts. These components are known for offering high performance, efficiency and durability.

Following facilities available at Factory:

- CNC Machining Center (MAKINO Max65-size 650 x 400 x 400-8000 rpm)

- CNC Machining Center (HAAS VF3-size 1000 x 500 x 600-15,000 rpm)

- EDM Spark Erosion (JOMERS JM430-50 amp generator, Tank size-1060 x 600)

- EDM Spark Erosion (JOMERS JM320-50 amp generator, Tank size-830 x 500)

- Surface Grinder (ALEX-500 x 200)

- Surface Grinder (BLOHM- 750 x 500 x 600)

- Lathe (PSG make)

- Radial Drill (Batliboi-BVR5-65 dia cap)

- Inspection TRIMOS Electronic height gauge (Model V 600)

- Inhouse Die Polishing

- CAD CAM Workstation (Pro Engineer Delcam-Powermill)

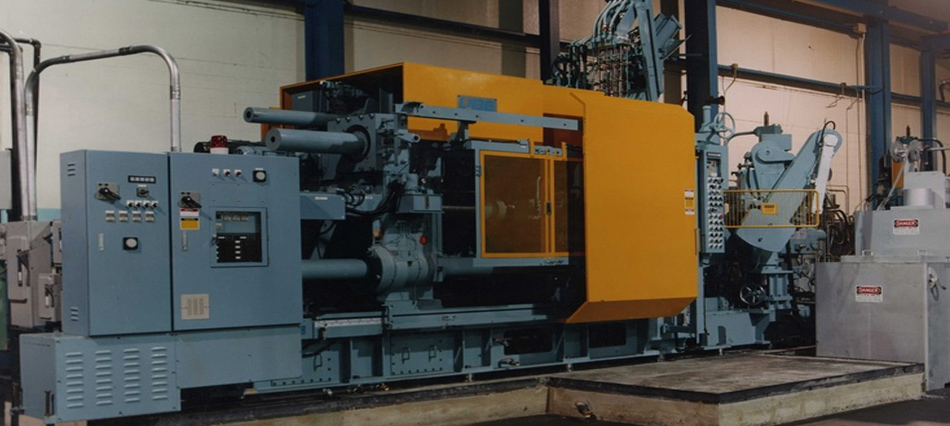

Die Casting

Following facilities available at Factory:

Following facilities available at Factory:

- CNC Machining Center (MAKINO Max65-size 650 x 400 x 400-8000 rpm)

- CNC Machining Center (HAAS VF3-size 1000 x 500 x 600-15,000 rpm)

- EDM Spark Erosion (JOMERS JM430-50 amp generator, Tank size-1060 x 600)

- EDM Spark Erosion (JOMERS JM320-50 amp generator, Tank size-830 x 500)

- Surface Grinder (ALEX-500 x 200)

- Surface Grinder (BLOHM- 750 x 500 x 600)

- Lathe (PSG make)

- Radial Drill (Batliboi-BVR5-65 dia cap)

- Inspection TRIMOS Electronic height gauge (Model V 600)

- Inhouse Die Polishing

- CAD CAM Workstation (Pro Engineer Delcam-Powermill)

Aluminum Die Casting

We offer premium quality range of Aluminum Die Casting to our esteemed clients. This product is fabricated using the best quality raw material and latest technology and it is designed with high precision in order to meet the set international quality standards.

We offer premium quality range of Aluminum Die Casting to our esteemed clients. This product is fabricated using the best quality raw material and latest technology and it is designed with high precision in order to meet the set international quality standards.

Following facilities available at Factory:

- CNC Machining Center (MAKINO Max65-size 650 x 400 x 400-8000 rpm)

- CNC Machining Center (HAAS VF3-size 1000 x 500 x 600-15,000 rpm)

- EDM Spark Erosion (JOMERS JM430-50 amp generator, Tank size-1060 x 600)

- EDM Spark Erosion (JOMERS JM320-50 amp generator, Tank size-830 x 500)

- Surface Grinder (ALEX-500 x 200)

- Surface Grinder (BLOHM- 750 x 500 x 600)

- Lathe (PSG make)

- Radial Drill (Batliboi-BVR5-65 dia cap)

- Inspection TRIMOS Electronic height gauge (Model V 600)

- Inhouse Die Polishing

- CAD CAM Workstation (Pro Engineer Delcam-Powermill)