Wago Relay

We are proud to serve our clients with high quality Terminal Blocks And Connectors manufactured by WAGO. For more than 50 years, WAGO has been successfully functioning on the principle of innovation. WAGO has raised the bars with its industry changing technologies, revolutionary new products and also efficient services, concepts and people working behind the scene that are essential to attain success.

Terminal Blocks And Connectors

We offer Terminal blocks and connectors.

Our range includes:

Get Quote

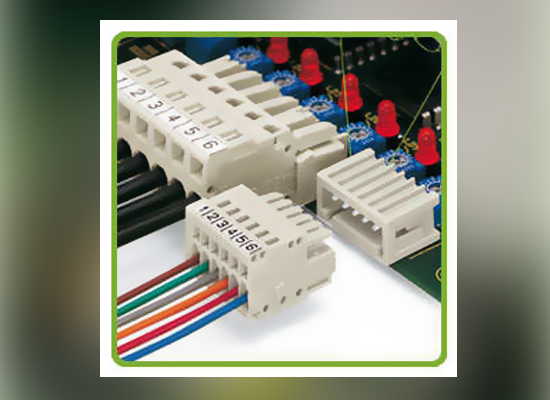

WAGO Pluggable PCB Terminal Blocks

Whether you are using modular socket terminal blocks, 2-wire socket terminal blocks, socket terminal strips or MICRO junction and distribution connectors for EIB applications - we have the right PCB terminal blocks to meet your every need.

Get Quote

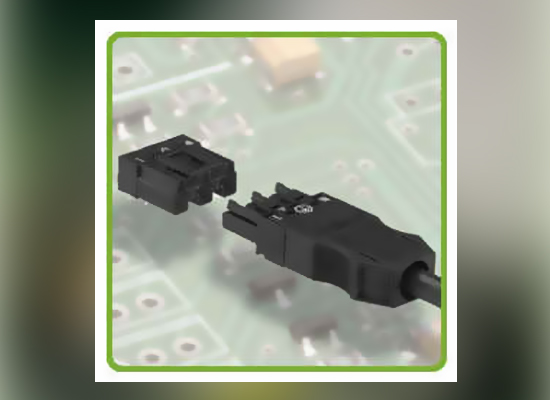

WAGO PCB Plug-In Connectors

The universal connector system. In the diameter range up to 2.5 mm², the MULTI CONNECTION SYSTEM provides all prerequisites for continuous system wiring.

Applications :

Advantages :

Get Quote

Wago Winsta PCB Plug-In Connectors

Pluggable connection for PCBs up to 25A, codable. Looping of the feed-through wiring via dual connection. CAGE CLAMP® S connection for all types of conductors - direct connection of solid conductors also possible.

Get Quote

WAGO Feed-Through Terminals

Panel feed-through terminal blocks, and PCB feed-through terminal strips for conductor termination external to the enclosure.

WAGO's latest addition to the family: Series 828 tool-less panel feed-through terminal block for up to 6 AWG.

Get Quote

WAGO Pluggable PCB Connectors

Synthesis from PCB terminal blocks and plug-in connectors with CAGE CLAMP® connection. For the safe integration of PCB modules in the system wiring.

Get Quote

WAGO Connectors For Special Applications

Using these branch plug-in connectors (this application: an elevator system), any location can be tapped via the strip, without the need to bare a conductor. Tapping occurs via the pin strips with CAGE CLAMP® connector.

Get Quote

WAGO Side-Entry Rail-Mounted Terminal Blocks

For more than 20 years, the WAGO rail-mounted side-entry terminal blocks (as well as WAGO disconnect terminal blocks for test and measurement) with CAGE CLAMP® connection technology, have been providing safe connections.

Get Quote

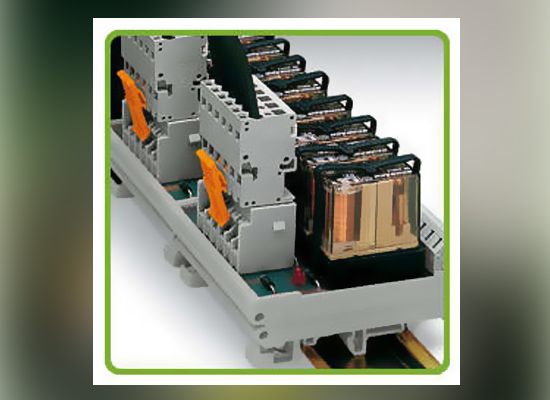

WAGO Functional Terminal Blocks

Withstanding heat and cold: WAGO rail-mounted terminal blocks up to 35mm2/AWG 2. Disconnect terminal blocks for test and measurement in current transformer circuits and disconnect terminal blocks in outdoor distribution cabinets of a power station transformer substation.

Get Quote

WAGO PCB Terminal Blocks And Connectors

The largest range from the industrial leader

WAGO offers a comprehensive program of PCB terminal blocks for the connection of PCBs in your device environment. For conductor diameters between 1 mm² to 1 mm², in metric or imperial pin spacings of 1 - 1 mm, or from 1 - 1 mm respectively, a suitable solution is found for everyone - of course in screwless connection technology with CAGE CLAMP®, push-wire or the versatile CAGE CLAMP® S connection.

Get Quote

Wago Classic Rail-mounted Terminal Blocks

Provide order, neatness and maintenance-friendliness in the distribution panel: WAGO TOPJOB® installation multilevel and rail-mounted terminal blocks.

1. TOPJOB® is WAGO's terminal block product line that specializes in the high demands placed on electrical installation. Maintenance-free, no screws, and used for conductor sizes 2.5 mm² to 35 mm² - features that round out this product line.

2. Both the N-disconnect and the "lock-out" features make topJob easy to handle and safe during installations. This is supported by the building standards set by Rheinisch Westfälischen TÜV.

3. With only a 91mm length perpendicular to the carrier rail, TOPJOB®'s compact design is ideal for building installations.

Get Quote

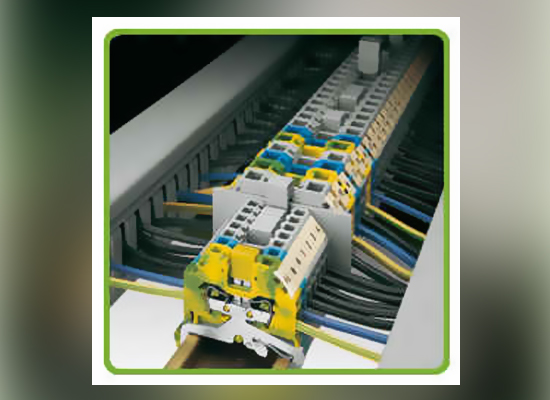

WAGO Rail-Mounted Terminal Block Systems

TOPJOB® S - The range of rail-mounted terminal blocks. Simply brilliant. One range of rail-mounted terminal blocks that can fulfill all industrial and Ex applications, as well as those for building installations. Thanks to CAGE CLAMP® S technology, the TOPJOB® S rail-mounted terminal blocks for the DIN 35 carrier rail are the smallest on the market. The compact size helps minimize costs through the reduction of panel space used, as well as smaller enclosures and junction boxes.

Get Quote

WAGO Modular Terminal Blocks

Maximum Impact, Minimum Size

WAGO 2273 Series: Small is Big

The new "WAGO" is more than 50% smaller than the original 273 Series. Safe, secure and error-free connection of solid conductors is guaranteed by the transparent enclosure.

Get Quote

WAGO Rail-Mounted Terminal Blocks

Front-entry rail-mounted terminal blocks

Rail-mounted terminal blocks with CAGE CLAMP® connection. Whether they are through, ground (earth) conductor and shield (screen) terminal blocks, angled and horizontal type; distribution, high-current and multilevel terminal blocks - we have the ideal terminal block with front-entry wiring for any field.

Get Quote

WAGO Compact Rail-Mounted Terminal Blocks

Compact and versatile :

WAGO front-entry rail-mounted terminal blocks of series 870 with CAGE CLAMP® DIN 15 and DIN 35 rails.

Get Quote

Wago Shield Connection System

Today's industry requires that equipment have some form of electromagnetic compatibility (EMV). Minimizing sensitivity and transmission of magnetic flux provides achieves this goal. These magnetic fluxes can cause many different types of errors (frequency converter, quicker load change, etc).

Taking measurements is the only way to detect any interfering magnetic fluxes. When they are detected, precautions need to be taken such as a good grounding of the enclosure and a large area for the shielding (skin-effect when the magnetic fluxes are at high frequency). WAGO's shield system offers a broad range of very effective products. Both the EMV and the nominal values given will be controlled within the expected range. Installation at a later date is also a simple process. The WAGO shield system is insulated and can also be used as a grounding potential.

Get Quote