Products Range List

Plastic Extrusion Machinery

We are instrumental in providing the clients with a wide range of Engineering Equipment, which is known for its exceptional quality and delivers an unmatched performance. Our range is in tandem with the international quality standards and is much better than the one that our industry counterparts offer. This is because we see to it that only high-grade material is used for the purpose of production and carry out the manufacturing process with the aid of cutting-edge technology. Our range comprises the following products:

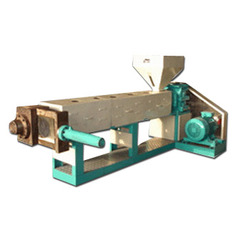

1. Plastic Extrusion Machinery Capitalizing on the painstaking efforts that our team puts in, we have been successfully providing our clients with Plastic Extruder Machine, which performs exceptionally. We especially approach some of the leading vendors of the industry to source high-grade material for manufacturing this machine, so as to ensure that it is up to the mark. The production of this machine is carried out using the latest machinery at our state-of-the-art manufacturing facility. We deliver this machine in a timely manner and see to it that the clients can easily afford it.

Capitalizing on the painstaking efforts that our team puts in, we have been successfully providing our clients with Plastic Extruder Machine, which performs exceptionally. We especially approach some of the leading vendors of the industry to source high-grade material for manufacturing this machine, so as to ensure that it is up to the mark. The production of this machine is carried out using the latest machinery at our state-of-the-art manufacturing facility. We deliver this machine in a timely manner and see to it that the clients can easily afford it.

Material:

We use high-grade material to manufacture this machine, so as to live up to the expectations of our clients. As a matter of fact, we use superior quality screws and cylinders in this machine and see to it that these are made of alloy steel (EN-24 for hardened / EN-41B for gas nitride screw & cylinder). High temperature / high pressure conditions are prevalent inside the extruder and therefore we make use of surface treated screws and cylinders, which can easily operate under these circumstances. To make this product a long-lasting one, we fabricate its stand using thick channels, which of course are of exceptional quality.

Design:

We design the screw in tandem with the material that needs to be processed and see to it that the cylinders are provided with ample thickness, so as to ensure that these can easily withstand internal pressure as well as regular wear & tear. To mount the cylinders, we make use of a helical gearbox thatís fitted with a heavy duty thrust bearing, along with cooling oil, thereby ensuring maximum efficiency and low maintenance. In order to ensure that there is minimum vibration even when the extruder is being operated at its maximum rated speed, we use a specially designed stand that serves the purpose. To make sure that this product works efficiently, we properly align the standard AC motor that powers the extruder with the gearbox.

Temperature Control:

The control cabinet brings along an automatic cut-off system and makes use of digital temperature controllers, good quality heaters and thermocouples to regulate the temperature of the cylinders. Moreover, we provide blowers with such extruders that need a more accurate temperature control.

Dies:

Several dies/machines are used for the production of this machine, some of which are as follows:

- Plastic Reprocessing / Recycling Plant

- Plastic Blow Film Plant

- Pipe Plant [PVC, LDPE, LLDPE, HDPE]

- PVC Profiles [Casing-Capping, Symmetrical Profiles]

Salient Features:

- Optimum performance

- Sturdy construction

- User-friendliness

Manufactured using sophisticated technology and quality material, our range of Plastic Extrusion Machine has earned acclamation from the clients for high performance. Our range is capable of enhancing aesthetics, saleability and opacity of the films. These machines find extensive application in varied industry purposes and is manufactured using graded metals & alloys.

Manufactured using sophisticated technology and quality material, our range of Plastic Extrusion Machine has earned acclamation from the clients for high performance. Our range is capable of enhancing aesthetics, saleability and opacity of the films. These machines find extensive application in varied industry purposes and is manufactured using graded metals & alloys.