Products Range List

Plastic Extrusion Accessories

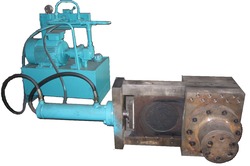

Our company offers superior quality Industrial Mixer, which is widely appreciated for its several features like abrasion resistant, dimensional accuracy and safe operation. It is commonly used in chemical engineering and other related sectors. This is made in accordance with the international quality standards and is dispatched in the given time frame. The high-grade metal that we use for the manufacturing ensures durability and longer applicability of the products.

1. Agglomerator

Body:

Agglomerate are made of M. S. With S. S. 304 lining. Body made in two parts. Lower body of less height to aid in easy removal for setting of blades.

Body:

Agglomerate are made of M. S. With S. S. 304 lining. Body made in two parts. Lower body of less height to aid in easy removal for setting of blades.

Housing:

Houses the shaft fitted with the mixer blades. Consists of two heavy-duty bearings. Water cooling on housing helps to keep the temperature down to a minimum even at the high operating speed.

Blades:

intensive mixing blades are provided with scraping arrangement. Blades are H. C. H. C. (high carbon high chromium) tipped with a hardness of 60 on the rockwell c scale. Blades are fitted in accurately machined slots and provided with locking plates to allow proper fitting over the entire blade width. High-tension bolts are used for fitting blades.

Motor:

Agglomerate is fitted with a ac motor according to required capacity.

Output:

A batch of 15 Kgs to 25 Kgs can be processed based on capacity.

We source high-grade material from leading vendors of the industry to manufacture matchless Grinders, which are widely acknowledged amongst our clients for their incredibly quality. Our focus lies on providing the clients with value for their money and hence we lay utmost emphasis on the quality of our grinders. We see to it that the production is carried out using technologically-advanced machinery and after proper research, so as to ensure that only innovative products are delivered at the clients’ end.

We source high-grade material from leading vendors of the industry to manufacture matchless Grinders, which are widely acknowledged amongst our clients for their incredibly quality. Our focus lies on providing the clients with value for their money and hence we lay utmost emphasis on the quality of our grinders. We see to it that the production is carried out using technologically-advanced machinery and after proper research, so as to ensure that only innovative products are delivered at the clients’ end.

Rotor:

The grinder that we offer comes with a one-piece rotor, which is made using mild steel. In order to enable dynamic balancing, we see to it that this rotor is accurately machined.

Chambers:

We leave no stone unturned to deliver what we promise and hence make use of thick mild steel plates to manufacture the chambers of our grinders. As a matter of fact, we use superior quality cast iron to make the side parts. In case of grinders that are above 15” in terms of size, we generally make use of mild steel. Further, we use heavy duty bearings to house the rotor in the side parts.

Blades:

The blades of the grinder are fitted using high-tension bolts and are tipped with H.C.H.C. (High Carbon High Chromium). These blades are known to have a hardness of 60 on the Rockwell C Scale. Moreover, we see to it that fixed blades are housed inside the chambers and that these are provided with adjusting bolts. In order to ensure that the blades remain in their place and do not get dislocated, even when these are subjected to heavy operating loads, we provide a separate arrangement that takes care of these issues.

Bottom Screen:

The bottom screen of the grinder is made using Mild Steel Plate and is provided with perforated holes.

Collecting Bin:

We make the collecting bin using galvanized steel, so as to ensure that it lasts really long.

Salient Features:

- Incredible durability

- Ease of usage

- Low maintenance

Our clients can avail from us, High Speed Mixer, which is one of the best ones available in the market, in terms of quality. We have literally outshone many of our competitors in this context, as this product of ours is made using the best available raw material and of course the latest technology. This easy-to-use mixer is widely acknowledged amongst our huge clientele for its superior quality and cost-effective price. We see to it that we deliver what we promise and that too within the stipulated time frame.

Our clients can avail from us, High Speed Mixer, which is one of the best ones available in the market, in terms of quality. We have literally outshone many of our competitors in this context, as this product of ours is made using the best available raw material and of course the latest technology. This easy-to-use mixer is widely acknowledged amongst our huge clientele for its superior quality and cost-effective price. We see to it that we deliver what we promise and that too within the stipulated time frame.

Body:

We give due consideration to the requirements of the clients while manufacturing this mixer and hence make use of either M.S. or S.S. or M.S. with S.S.304 lining. In order to prevent metal to metal contact and ensure that the material doesn’t escape, we provide adequate rubber padding between the body and the lid. To ensure that the material cools off quickly and no lumps are formed, the body can also be water jacketed from outside, if required.

Housing:

The housing comprises two heavy duty bearings and has a shaft that’s outfitted with mixer blades. Water cooling on the housing plays a crucial role in keeping the temperature down to minimum, even when the operating speed is relatively high.

Blades:

As per the variegated requirements of our clients, we either make use of M.S. or S.S. for manufacturing the blades. In order to achieve proper mixing, it is essential that the two blades are correctly positioned.

Motor:

The mixer that we offer is outfitted with a 15hp or 20 hp motor, as per the application specific requirements of our clients.

Output:

Our mixer is highly efficient and this is evident from the fact that a batch of 25kgs to 30kgs can be easily processed and that too in a short time span of around 7 minutes.

Salient Features:

- Optimum output

- Exceptional durability

- Low maintenance

We are instrumental in providing the clients with Caterpullar, which is extensively used as a haul-off unit for pipe plants as well as for profile extrusions. This product is made using high-grade material and is fitted with two rubber belts that are driven by an A.C. drive unit. Clients prefer this product to the other options available in the market, as the speed of the unit can be easily controlled within a range of 0 to 20 ft. per minute. As a matter of fact, this product is designed in such a manner that even the centering of the belts and the opening between the belts can be manually adjusted and that too with utter ease. It can be concluded that the belts provide proper pull of the extrude, thereby playing a major role in the functioning of this product.

We are instrumental in providing the clients with Caterpullar, which is extensively used as a haul-off unit for pipe plants as well as for profile extrusions. This product is made using high-grade material and is fitted with two rubber belts that are driven by an A.C. drive unit. Clients prefer this product to the other options available in the market, as the speed of the unit can be easily controlled within a range of 0 to 20 ft. per minute. As a matter of fact, this product is designed in such a manner that even the centering of the belts and the opening between the belts can be manually adjusted and that too with utter ease. It can be concluded that the belts provide proper pull of the extrude, thereby playing a major role in the functioning of this product.

Salient Features:

- Sturdy construction

- Exceptional performance

- Low maintenance

Our clients can avail from us, a two-station Winder, which is provided with an A.C. motor and two torque motors. This product is outfitted with a mechanical arrangement that helps adjust the tension & speed and probably this explains why it is extensively used for winding film extruded by blow film extruders. The winder that we offer comes with an ebonite roll and a synthetic rubber roll. Moreover, in order to cater to the application specific requirements of our clients, we can also provide a slitting arrangement on the winder. The width of the rolls depends on the maximum width of the film that needs to be extruded.

Our clients can avail from us, a two-station Winder, which is provided with an A.C. motor and two torque motors. This product is outfitted with a mechanical arrangement that helps adjust the tension & speed and probably this explains why it is extensively used for winding film extruded by blow film extruders. The winder that we offer comes with an ebonite roll and a synthetic rubber roll. Moreover, in order to cater to the application specific requirements of our clients, we can also provide a slitting arrangement on the winder. The width of the rolls depends on the maximum width of the film that needs to be extruded.

- High durability

- Optimum performance

- Ease of usage