SILROBOWELD it is modern 2-to 6KW laser welding delivers high quality, high precision weld that is not possible with conventional CO2 welding Fiber laser technology allows to processes different types of thickness and materials, including similar and different material. SILROBOWELD operates in standard laser safety booth to protect user from shorter wavelength emitted by fiber laser. SILROBOWELD its takes higher level of precision and productivity using fiber laser processes material such as brass, copper, and aluminum. Fiber laser technology is with unmatched beam quality and electrical saving, due to this requires less maintains to oscillators to generate beam. In SILROBOWELD teaching is done with inline CCD camera which is easy , fast and accurate teaching of welding path. Another key featuresis rotating mirror in welding head, which helps to rotate beam direct path of welding, it can make any shape of laser beam like 8, O, line (vertical or horizontal)

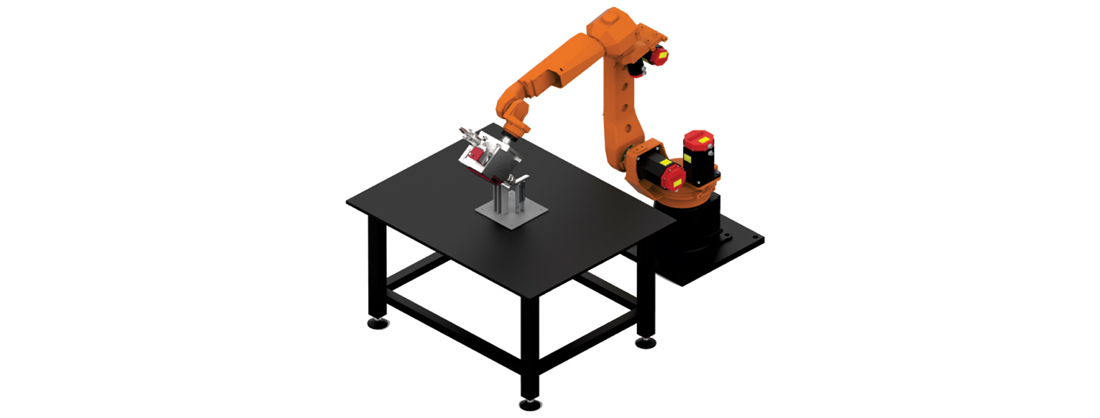

processes flexible cutting for formed three Dimensional metal components with adoption of specialized laser cutting head, high accuracy tracking system and high accuracy industrial Fanuc robot. Taking advantage of robot's flexibility and quickness, it can cut three dimensional as well as irregular shaped components as per different work piece sizes. It is capable of teach programming or offline programming to indicate various processing parameters. Laser cutting head is equipped with specialized auto focus sensors to focus precisely. As a top of the line innovation of laser application technology, 3D laser cutting innovation has expanded generally utilized as a part of the Automobile manufacturing industry for auto parts, such as entire auto body, door, trunk, rooftop etc. It reduces mold cost and quicker turnaround time in development process with better processing efficiency. Our range of models offers metal as well as non-metal components to cut with different laser sources as well as wide range of laser power.