Diesel Fired Oven

Diesel Fired Oven

TECHExpert manufactures a wide range of Diesel Fired Ovens to suit assortment of industrial process applications identified with heating. We offer a complete package that includes technical specifications, design, manufacturing, installation & commissioning process. Our DieselFired Ovens are ideally suitable for an extensive variety of heating applications. They are available in various sizes, types and temperature ranges.

We manufacture Diesel Fired Ovens that are energy proficient with a minimum gradient over their widths and heights. A uniform dissemination of heat guarantees uniform baking of all the components.

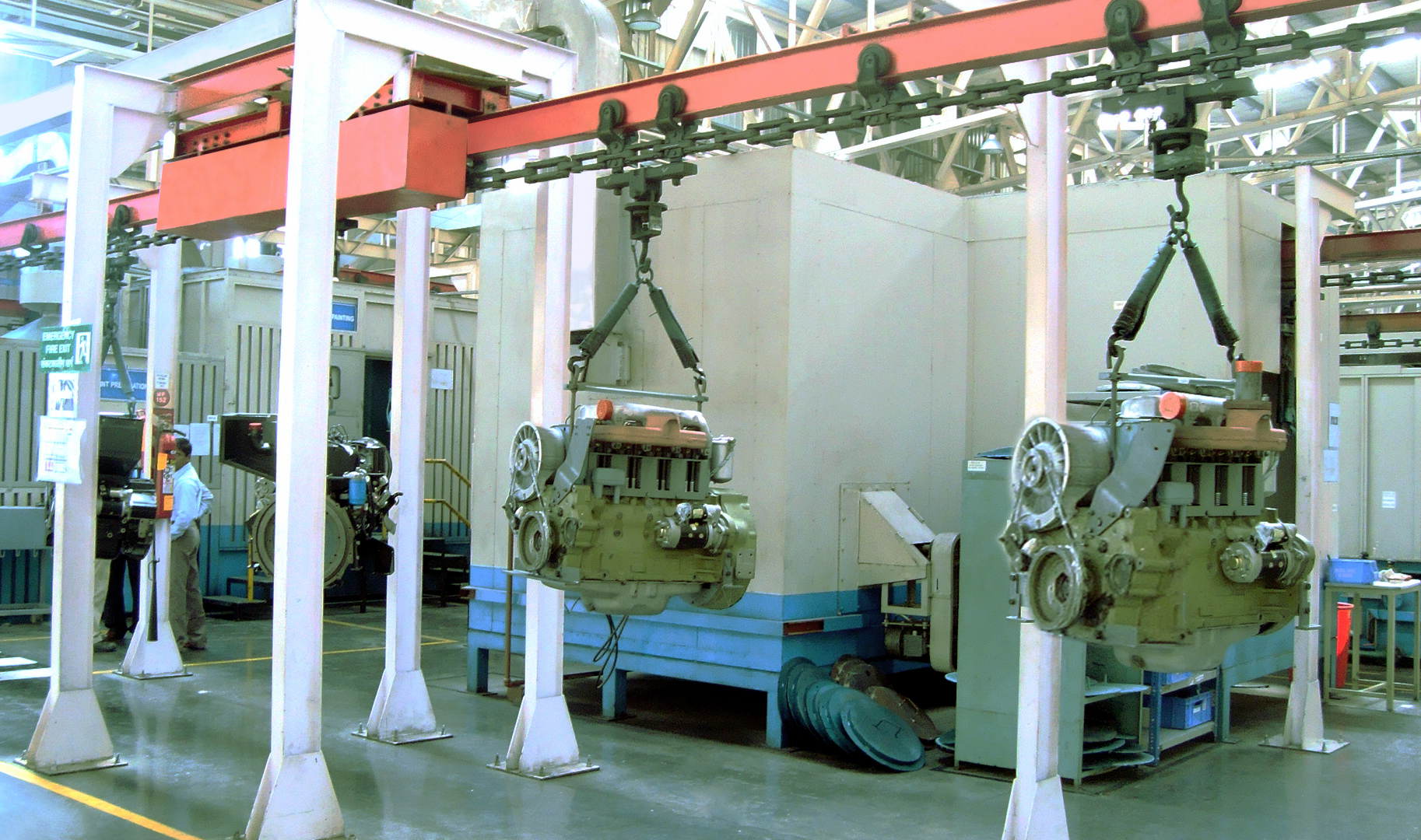

Our Diesel Fired Ovens are integrated with an extensive range of batch type as well as Overhead chain conveyors, I Beam Conveyors, Flight Bar Floor Conveyors, and Roller Conveyors. We are considered to be the best in the industry for ensuring that our ovens are pre-assembled, wired and tested prior to dispatch. The heating media are used with indirect heat exchanger. All ovens are constructed with high quality components using our unique modular construction method. All ovens are constructed with high quality components using our unique modular construction method.

TechExpert's batch box type oven is available in various ranges. Medium and big size industrial ovens are built in Modular cassette and expandable construction with a unique feature of world class Rock Wool insulation for minimum heat loss.

Why you should use TECHExpert Diesel Fired Oven

FEATURES:

APPLICATIONS: