ABOUT US

We introduce ourselves as a leading manufacturer of sheet metal components & Seat Slider, Height Adjuster Assemblies, Fuel Tank Cap Assemblies, since 2005. Right now we are supplying to major suppliers OEM and they are directly supplying to TATA MOTORS, M&M, Piaggio, Textile industries, Electrical industries etc. We are also manufacturing Cinema Seat Slider Assemblies and developing Slider Assemblies and height adjuster for Luxury Bus Seat. We are also taking value-engineering projects of mechanisms used in automobile.

We are an ISO-9001: 2015 certified company. We are very much aware of present quality requirement as per TS16949. We are working for continuous improvement in product quality and better working environment.

Our total shop floor area is about 15,000 Sqft. We are having mechanical power presses range 10 tonne to 150 tonne. All components having surface treatment , heat treatment and special processes we are doing outside from approved sources.

We are having separate assembly unit with 1000 Sqft area. We assemble all tools in house with our own Design. We always accept challenging and critical product development. We are having a very good technical team with experienced and skilled operators and trained supervisors. We can assure you just in time supply with Quality products. Presently we are working only 10 hours, rest we have spare capacity to develop more components.

We can add any conventional and Special purpose machine if required for special purpose components. Sir, please give some challenging critical job to justify our capability and skilled.

Company Profile

Vishwadeep Enterprises is leading manufacturers of sheet metal press parts, Welded Assembly, Seating Mechanisms, Torsional Couplings and Flexible Couplings.All Products are having wide range of application like

• Automotive Industry

• Electrical & Electronics Industry

• Textile Industry

• Railways

• Defense Products

• PSUs

ISO 9001:2008 Certified Company

Manufacturing

Follows procedure of ISO 9001:2008.

• Always updating resource, manufacturing processes and technologies related to innovations.

• Updates to improve strategic manufacturing capabilities to meet customer satisfaction.

• Has a facility of Power Presses ranging from 10 T to 150 T, Resistance welding 20KVa, MIG welding, Tool Room.

• Focuses long term basis vendor relationship for Product & Quality awareness

• Working for continuous improvements in Quality and better working environment.

History

» 2006 Set up with Press shop (Pressing Range 20T to 50T)

» 2007 Set Up with Press Shop (Pressing Range 20 T to 100 T)

- Certified With Quality Management System ISO : 9000

» 2008 Setup with Press shop with Fabrication

- Set up with own Tool Room Activity

- Started Mfg seating Mechanism ,Fuel Tank Cap Assy

» 2009 Set up added with Pressing up to 200 T

- Added variety seating Mechanisms range.

» 2010 Focused technology based Engg development

- Customized Value Engg & Value Added (VEVA ) Developments

» 2011 Started Mfg critical Mechanism ,Proprietary Assembly with customers needs

» 2017 Added 250 T power Presses 2 nos.

LIST OF MACHINARY AND EQUIPMENTS

| Sr no | Name of machinery | Capacity | Qty (no) | Make | Table Size | Shut Height | Stroke Length |

| 1 | Power press (Mech ) | 250 T | 2 | Syndicate | 1000 x 1000 | 500 | 250 |

| 2 | Power press (Mech ) | 200 T | 2 | Syndicate | 850 x 735 | 400 | 200 |

| 3 | Power press (Mech ) | 150 T | 2 | Ravi | 670 x 735 | 400 | 150 |

| 4 | Power press (Mech ) | 100 T | 2 | Mankoo | 600 x 660 | 450 | 150 |

| 5 | Power press (Mech ) | 75T | 1 | Ravi | 550 x 610 | 400 | 75 |

| 6 | Power press (Mech ) | 50T | 2 | Ravi | 500 x 460 | 250 | 75 |

| 7 | Power press (Mech ) | 30T | 1 | Shashikala | 300 x 450 | 250 | 65 |

| 8 | Power Press (Hydraulic) | 150 T | 1 | Maruti | 800 x 900 | 900 | 700 |

| 9 | Power press (Mech ) | 20T | 1 | Ravi | 300 x 450 | 200 | 65 |

| 10 | Projn cum Spot Weldg m/c | 25 Kva | 1 | JJ Arc | - | - | - |

| 11 | Co2 weldg m/c | 300 Amp | 3 | Indian Arc | |||

| 12 | Lathe | 5.5 ft | 1 | High Power | |||

| 13 | Grinding m/c | 4.5 ft | 1 | Jupiter | |||

| 14 | Drilling Machine | 1/2'' | 2 | Satyaprakash | |||

| 15 | VMC | 1000x500x500 travel xyz | 3 | STM |

LIST OF INSTRUMENTS AND GAUGES

| Sr. No. | NAME OF INSTRUMENTS | RANGE | QTY |

| 1 | Ht Gauge | 0-600mm | 01 |

| 2 | Surface Plate | 1000 x 1000 mm | 01 |

| 3 | Vernier Caliper (Digital ) | 0-300mm | 03 |

| 4 | Vernier Caliper | 0-200mm | 03 |

| 5 | Micrometer | 0-25mm | 01 |

| 6 | Micrometer | 25-50mm | 01 |

| 7 | Radius gauge | 0-25mm | 01 |

| 8 | Filler gauge | 0.1-1mm | 01 set |

| 9 | Thread plug gauge set | M4-M16 | 01set |

| 10 | Ring gauge set | M4-M16 | 01 set |

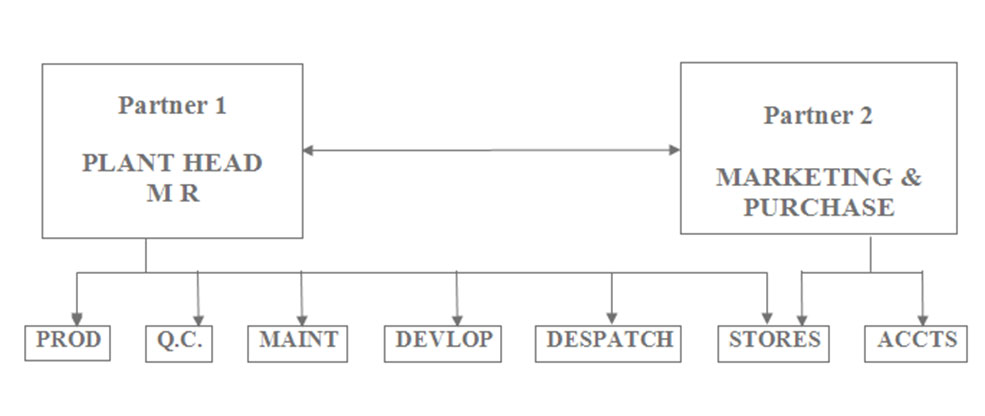

Oranisation Chart