Odour Control System is designed for installation in Close door Garbage / Trash Rooms for controlling or reducing the odour generated in Trash rooms. This odour is a result of decomposition of garbage in the bins at ambient temperatures. Odour can be controlled in different ways and in this unit, odorous gases are masked and dissolved by the herbal liquid. To achieve this, the herbal extract liquid is dispersed in the air in very small particle sizes ranging from 1-10 microns. These particles get attached to the molecules of odorous gases. This increases the weight of these molecules, they settle down and then biodegrade.

The Brush Cleaning System is designed to clean the internal cylindrical surface of the garbage chute. This is done periodically to maintain hygiene in the chute. It is installed at the top of the chute & operated by the control panel. Consists of a stiff nylon brush which is automatically lowered and raised in the chute. During this operation water is sprayed by sprinkler. Number of cycles can be set. The Brush Cleaning System is available in various sizes depending on diameter of the chute.

Rotary carousel with compactor is a system which facilitates the collection of garbage in more than one bin. Garbage bins are arranged on a rotary platform below the chute. When first bin is full it is moved to the next station and next bin come below the chute. At next station a vertical bin compactor shall compact the garbage in bins. This cycle continues till all bins on rotary platform are full. Once all the bins are full system gives an audio visual signal. Replace the full bins with empty bins and the system restarts.

Linear carousel with compactor is a system which facilitates the collection of garbage in more than one bin. Garbage bins are arranged on a linear motion platform below the chute. When first bin is full the vertical bin compactor at the same station shall compact garbage. This shall create further space to receive more garbage. The cycle continues till the first bin is "full". Then first bin moves ahead and next bin comes below the chute. The cycle continues till all the bins on linear platform are full. Once all the bins are full, system gives an audio visual signal. Replace the full bins with empty bins and the system restarts.

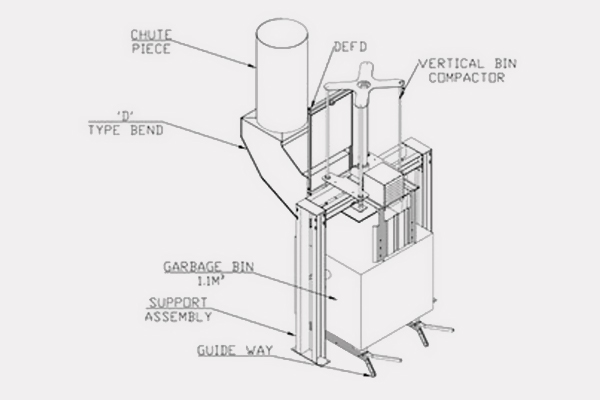

Chutes discharge the garbage into stationary bin below the chute. Once the bin is full the vertical bin compactor compacts the garbage. This creates further space to receive more garbage. The cycle continues till the bin is full. Once the bin is full system gives an audio visual signal. Replace the full bin with empty bins & the system restarts.

Clog warning system is designed to raise an alarm in case of chute clogging. This is based on non-contact sensing technology. The sensors work periodically to check clogging of garbage in chute. If the chute is clogged, it gives audio visual alert along with location of clog.

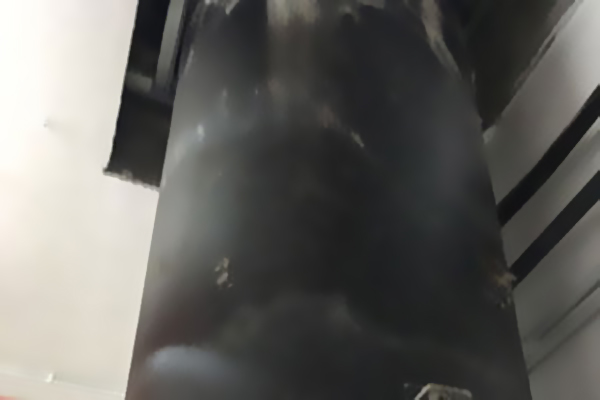

Sound Deadener is tar like thick paint applied on the outer surface of the chute with Airless gun to deaden the sound of the falling object through the chute. For example any metal object is disposed through chute will bang with the material (metal especially) to make sound. Because of this paint the sound levels, shall be reduced. It is normally 1.2mm to 1.5mm DFT (Dry Film Thickness).

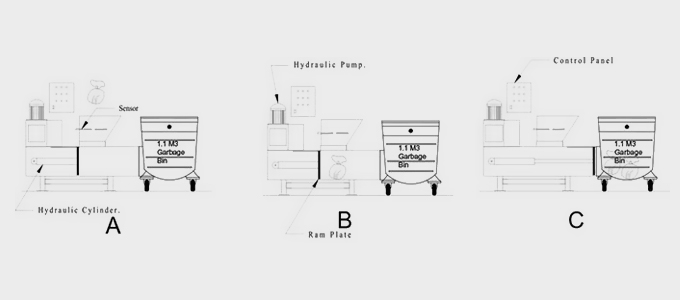

This system is used as chute feed compactor. As soon as the garbage bag is received through chute in compaction chamber, it is sensed by sensor beam. The hydraulic circuit is ON. Forward movement of Ram shall compact the garbage in special garbage bins attached to chute feed static garbage compactor. The Ram goes back to original position and cycle stops. The system gives an alarm at 80% and 100% full bin condition.