Our organization is boosted with state-of-the-art infra- structure like CAD based designing department, etc. Under the supervision of team of experts, machines are manufactured and tested as per ISO 9002 standards.

We commission steel plants on turn-key basis throughout the world, from concept to production.

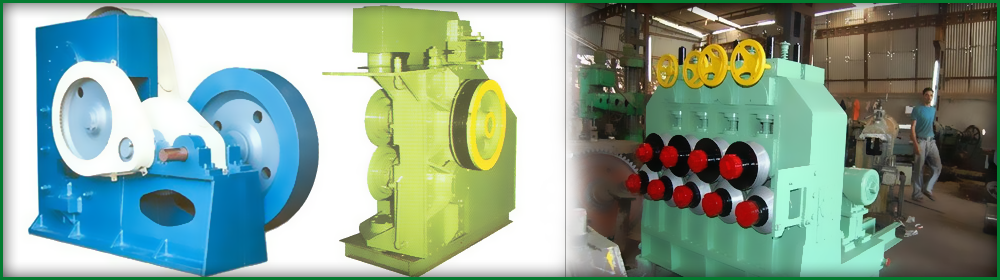

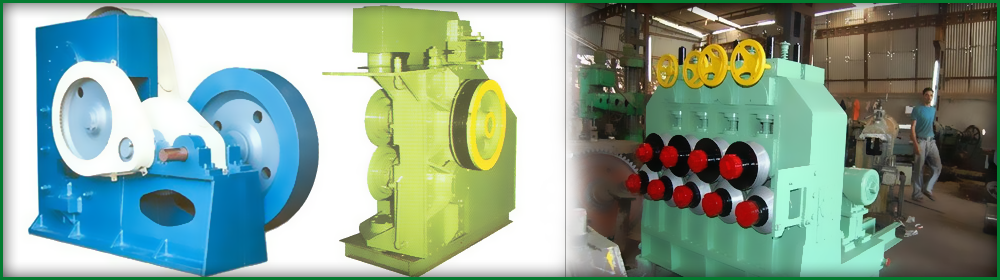

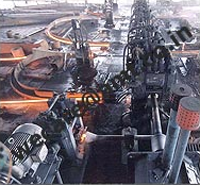

Aman Machine Tools is engaged in manufacturing, supply, erection and commissioning of steel rolling plants on a turn key basis. Designed using sophisticated production techniques and superior quality equipment, our steel rolling mill plants are known for their high performance and utility. Stable and robust in design, our range of steel rolling mill plants are designed in compliance with international quality standards and provided with several safety features to ensure operational safety and efficiency.

Item Code : SM-0001

Item Code : SM-0001

We offer our steel rolling mill plants in various types viz manual, semi-automatic, and fully automatic, depending on the requirements of our clients and the extent of investment and production required. Our clients can use our plants to roll out any item right from simple rounds, to steel to wire rod in coils, small flats to strips upto 14” width, H-beams to I-beams, channels, angles, plates and hot strips. These plants are available in production capacities ranging from 10 tons a shift to 400 tons a shift and can be configured to meet special specific requirements of our clients.

Item Code : SM-002

Item Code : SM-002

We manufacture and supply high quality, high efficiency steel rolling mill plants for different steel rolling requirements of our clients. The company has capacity to manufacture at least 1 plant per month. Our range of steel rolling mill plants are available in sizes of 6” to 24”, which can satisfy different industrial requirements. Our clients can use these steel rolling mill plants for small steel section as well as for manufacturing structural steel with capacity up to 400 tons per day. These are easy to operate and install and are provided with safety features to ensure safety and reliability.

Item Code : SM-0003

Item Code : SM-0003

Salient Features: -

Technical Specifications: -

Item Code : SM-004

Item Code : SM-004

Salient Features: -

Salient Features

Torsionally Rigid Steel Fabricated Body designed to Dampen vibrations

» Double helical Gears made of En-9, En-19, or En-24 Quality steel Forgings. Duly hardened

and

grounded.

» Amply Rated Bearings to work efficiently at Peak Loads

» Duble Oil Seals fitted on Shaft extensions

» Lubrication lines for Bearings, and Oil Splash system for gears are provided.

Item Code : CL-01

Item Code : CL-01

Salient Features: -

“'Amt' manufactures steel roling mill plants for the production of TMT/CTD Bars & Plain Rods in coil, which are used for wire drawing & fastener making. The coilers are available from a capacity of 150 kg & can go upto 500 kg depending upon the capacity of the mill.”

Item Code : PR-002

Item Code : PR-002

AMT manufactures various types and sizes of mill stands. Keyword of our equipment is reliability, ruggedness and ease of operation and maintenance. The salient features of our mill stands are that they are compact and simple design, they ensure quick roll changing and they require minimum maintenance. AMT offers various types of mill stands such as C.I.Casted stands, steel fabricated stands, steel casted stands, gun metal type stands, bearing type stands etc.

Salient Features

Item Code : GB-005

Item Code : GB-005

Technical Specification

• Available upto 8” Billet Cutting & 14” x 14” Slab Cutting Capacity

"amt" Billet shaering machines are fabricated from tested rolled plates from Main Producers , which are mild in composition, but sturdy in performance All the drive gears are manufactured out of forged En-9/19/24 Steel which id duly hardened and grounded. The shaft/Crank is forged En-8/9 steel. All the Bearing of these billet machines are of best quality, etc. Gun Metal Bushes are made with Copper Alloys to last longer life. All the billet machines are tested here for capacity and performance before despatch.

Salient Features

All the above capacities are for M.S Billet/Slabs. For Special Steel like S.S / Spring Steel/ Alloy Steel special machines are manufactured or request

Item Code : PR-03

Item Code : PR-03

Technical Specification

• Cutting Capacity 8 to 25 mm Hot Bras at 800 C

• Ranging Form 300 to 500 mm P.C.D

Salient Features

• Fixed and Swiveling type Rotary

• Fully Automatic with pneumatic controls, capable of cutting

hot ends (front and

rear) During Rolling, and fixed Lengths of

finished bars.

• Steel Fabricated body

• Circular Blades manufactured from High carbon, high chrome steel.

Item Code : PR-01

Item Code : PR-01

Salient Features

• Steel Fabricated Rigid Body

• Heavy Duty Spherical Roller Bearings

• Ph. Bronze Bushing on Crank Shaft

• 6/8 Gears

• Clutch / Non Clutch Type

• Stroke Per Minute 6-10

Item Code : TMB-01

Item Code : TMB-01

Technical Specification

'amt' manufactures latest design 'TMT' equipments for the manufacture of internationally approved quality of TMT Bars, the size range starting from 8 MM & upto 32 MM, which are generally used in Construction Industry throughout the world. 'amt' manufacture complete range of TMT equipments i.e. Quenching Box, Pirich Rods, Water Softening plants, cooling towers, high pressure pumps, Control Panels & testing equipments.

Item Code : GB-001

Item Code : GB-001

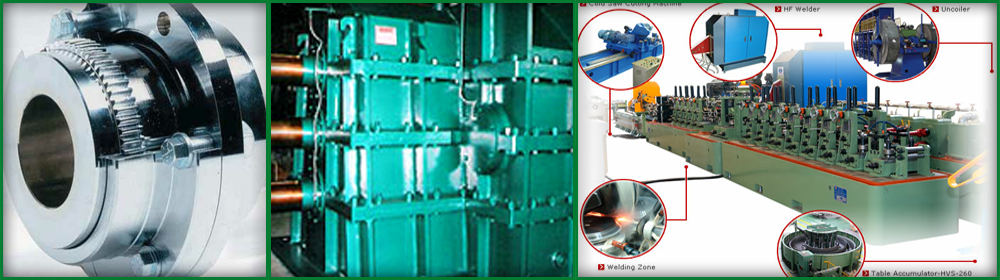

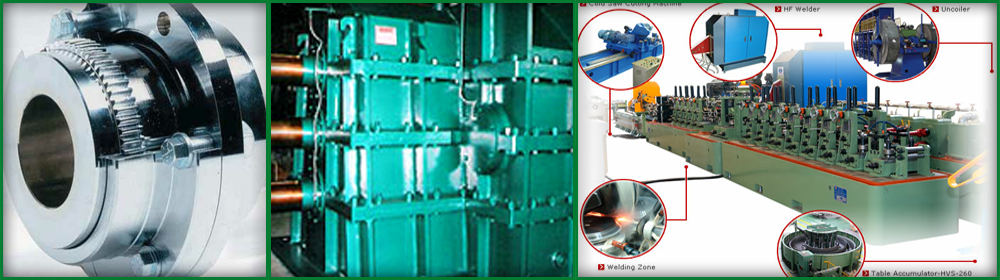

Gear Couplings are used for taking possible misalignment of shafts. These couplings saves power and bearing breakdown. Gear Couplings are made from En - 9 and Forged Stee. Currently gear couplings are available in size range no. 106-112, that are suitable for 8" to 24" SRM.

Salient Features: -

• Used for taking possible misalignment of shafts

• Saves power and bearing breakdown

• Made from En - 9 and Forged Steel

• Available in size range no. 106-112, that are suitable for 8"to 24" SRM

Technical Specifications:

• Made from Enforged Steel

• Size range no. 106 to 112, suitable for 6" to 24" P.C.D. rolling mills

Item Code : PR-06

Item Code : PR-06

Engineering of technically advanced speed increasers / reducers is one of our expertise. They are suitable to control the functional speed of various shearing machines. Attributed with modern features as per industry standards and requirements, our speed controlling machinery is extensively used across the industry. Robust in design, easy to maintain & user friendly operations, are some features that make our brand a preferred one. We design these machines with overload / power fluctuation management features and also ensure safety aspects.

Item Code : TC-01

Item Code : TC-01

Twin Channel is used in high speed rolling mills, where finished material can not be controlled manually. This equipment is used to control the flow of TMT bars and its length after TMT Box at the cooling beds