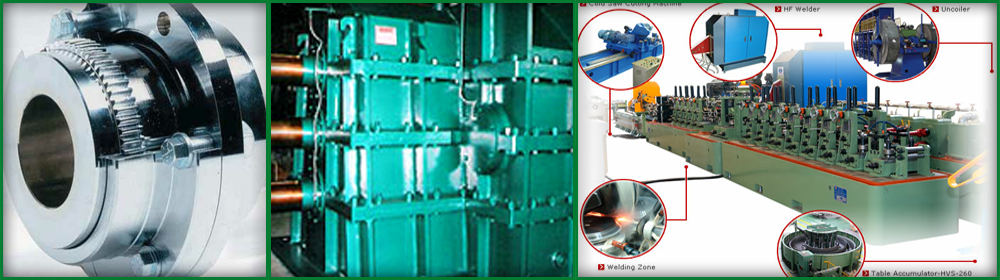

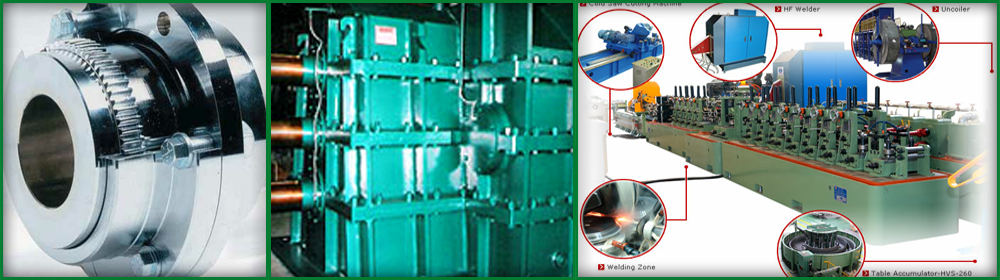

Our organization is boosted with state-of-the-art infra- structure like CAD based designing department, etc. Under the supervision of team of experts, machines are manufactured and tested as per ISO 9002 standards.

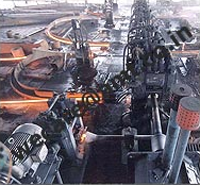

We commission steel plants on turn-key basis throughout the world, from concept to production.

We commission induction furnaces of the latest designs and of low power consumption. All the related equipments of steel melting plants like cooling towers, water softening plants, material handling equipments magnets, steel melting furnaces, electrical equipments, bottom plates, center columns, induction melting furnaces, ingot moulds, scrap, bailing presses, shreading machines are either manufactured by us or outsourced from reliable manufactures, who are associated with us for the last many years.

And providing satisfactory services to all our existing clients. After commissioning these melting plants, we supply all the consumables i.e. refractories, ramming mass, mortars, Cement & B.P. Sets regularly to these units.

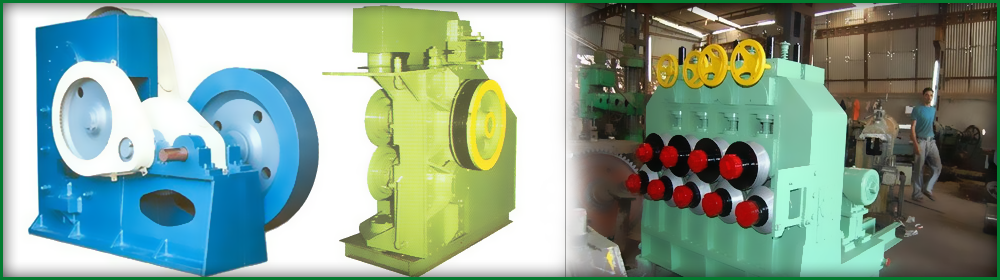

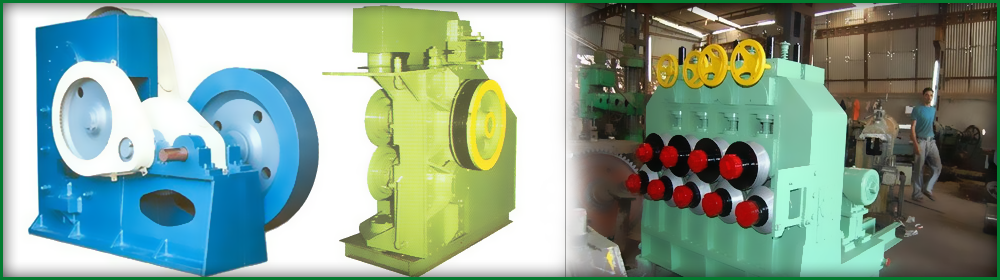

We manufacture all the basic & advanced tools & dies of steel melting plants, which are used for manufacture steel Ingoils & Billets.

Item Code MP-01

Item Code MP-01

1. Bottom Plates: C.I. Casted based plate in which moulds are set for the production of Ingots – The capacity can be from 20 to 40 pcs at a time.

2. Centre Column: Another C.I. Casted tool for pouring molten steel from induction furnace to different moulds for the production of ingots & other steel items

3. Moulds: We manufacture various types of moulds for different sizes for the production of ingots starting from sizes 3''x4'' to 7''-8'' & of slabs from 6''x8'' upto 8''-10''.

4. Material Handling Equipments: 'amt' manufacture the best quality of lot cranes & wire rope hoist, which are used in material handling in steel plants for capacity ranging from 5 tons to 100 tons.