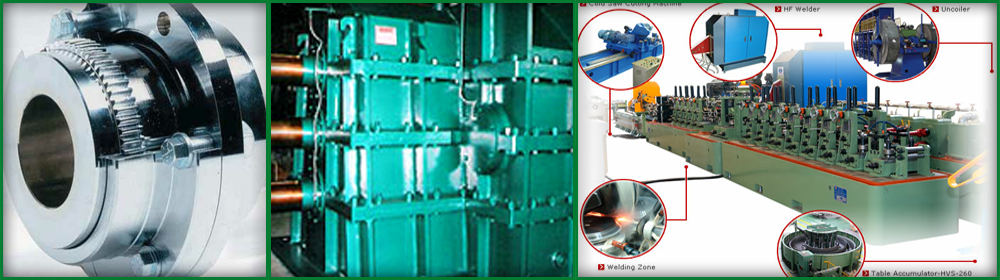

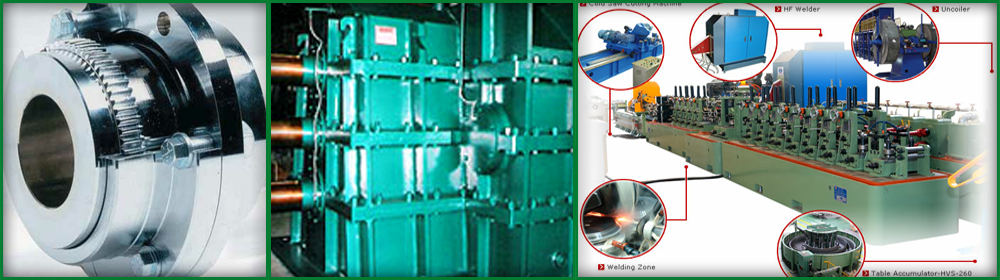

Our organization is boosted with state-of-the-art infra- structure like CAD based designing department, etc. Under the supervision of team of experts, machines are manufactured and tested as per ISO 9002 standards.

We commission steel plants on turn-key basis throughout the world, from concept to production.

We design, manufacture and supply a comprehensive range of material handling equipment and systems. These are produced as per the demanding industry standards and requirements and offer consistent high performance. Our equipment are easy to operate, safe to use and extensively used in a variety of applications such as mining, steel, thermal power, cement and construction industries.

Item Code : BEC-01

Item Code : BEC-01

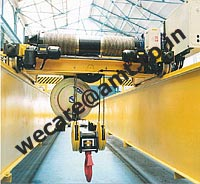

The main Structure of any E.O.T Crane consists of beams & end carriage on which entire operations are performed, the capacity & loaded factor are also determined on the basis of this structure. Amt takes special care about the quality of steels plates, only tested plates from main producers are selected, welding rods from Essab/Advani choses for joinery, profile cutting done on profile machines & all the tests & checks carried out to determine the strength & load carrying capacity of the crane.

Item Code : T-01

Item Code : T-01

All the critical equipments of the crane i.e wire – rope, chains, hooks, gears, motors, breaks are fully tested and carry tested certificates and have standard warantee. The capacity of the crane is tested at 150% of the loads and the same despatched only if found fully confirming to the specifications. The crane carries a standard guarantee for one year for any manufacturing defects. After sales services is a continuing policy of amt.

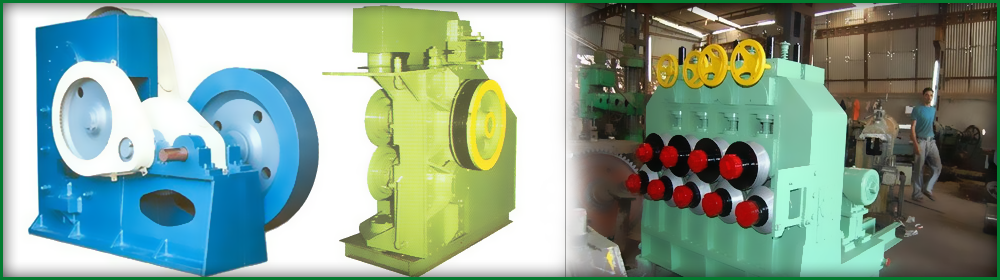

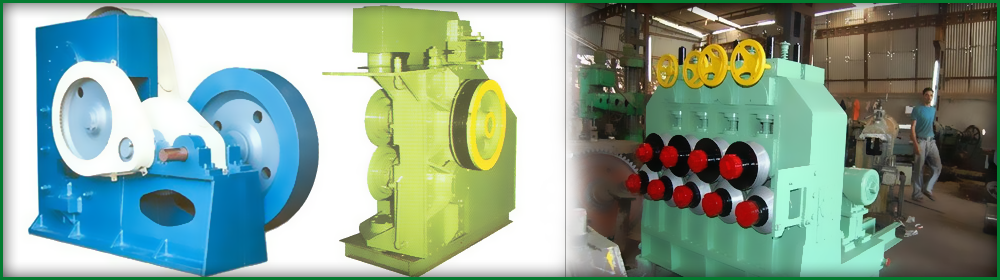

Amt has experience in design and manufacture of all types of cranes to meet your specific needs may be light crane, a heavy crane or a crane with a grab as apparent from diverse range shown here.

Item Code : GD-01

Item Code : GD-01

After the main structure, the next important part of any crane is its drive system. Amt manufactures all the drive components in its modern plant, most crucial being gear boxes, which are encased in graded C.I casted housings mounted on special steel shafts & on the very best breathings (SKF / NBC / ZKL) etc.

Item Code : DS-01

Item Code : DS-01

All the electric motors used are of slippering type, with B- class insulation and of reputed make i.e Kirlsoker / Crompton / Alstom on which electric- magnetic / E.H.T brakes of tested quality are used, because the entire working of E.O.T. Crane depends on safe and smooth operation of the brakes. To avoid chance of any accident, double safety by way of emergency control switch is provided to ensures security.

After the drive system, hoisting is equally important and here amt takes extra care- both in choosing wire ropes and hooks. Tested wire ropes of Usha Martin or equally reputed manufactures of size 6 x 37 with steel/fiber core are used which can take loads upto 150% of the standard capacity. The hook used is of tested EN-9 steel, duly forged and machined before fitting and tested to take loads of upto 200% of the capacity.