Gas Processing Systems

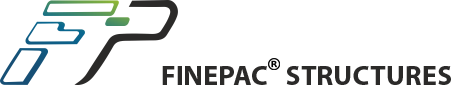

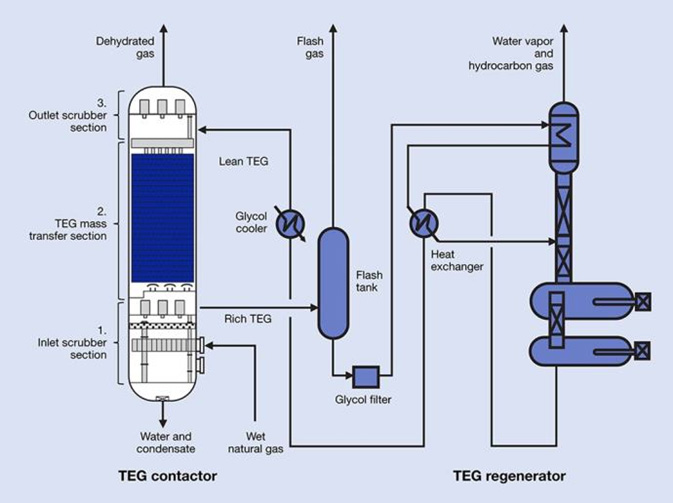

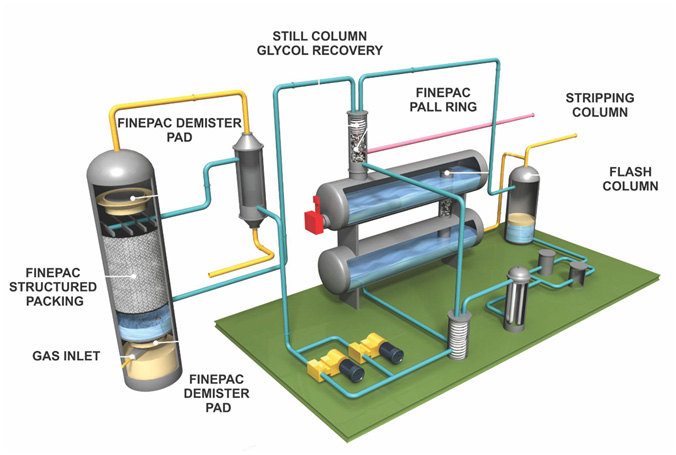

Gas dehydration is an important process in gas processing. The produced gas is saturated with water, which must be removed. If not removed it can create problems like corrosion, water condensation and plugs created by ice or gas hydrates. In addition other contaminants like H2S, CO2 and mercaptans must also be removed. Gas treatment systems like dehydration and gas sweetening removes these impurities and makes the gas suitable for transportation and further use.