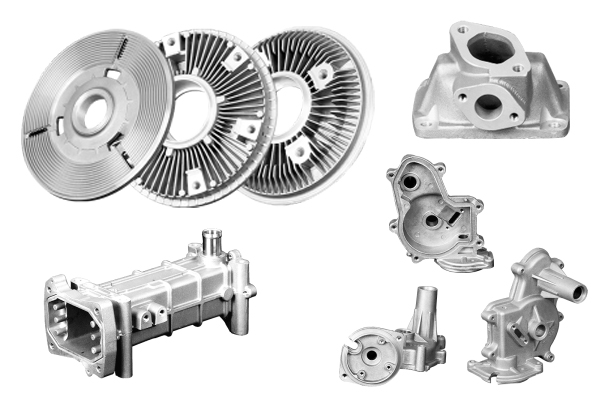

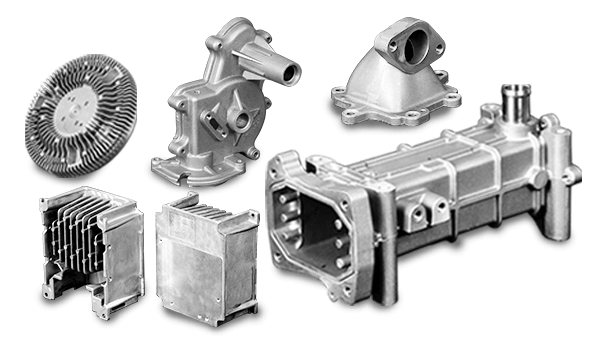

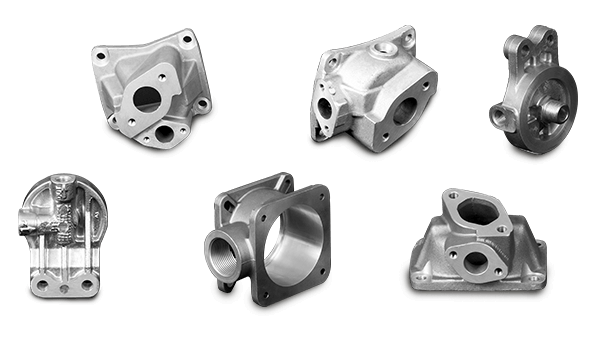

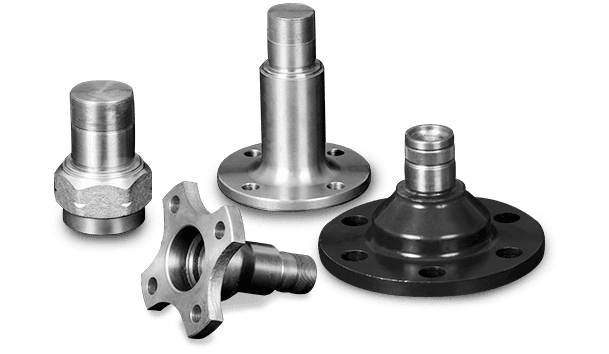

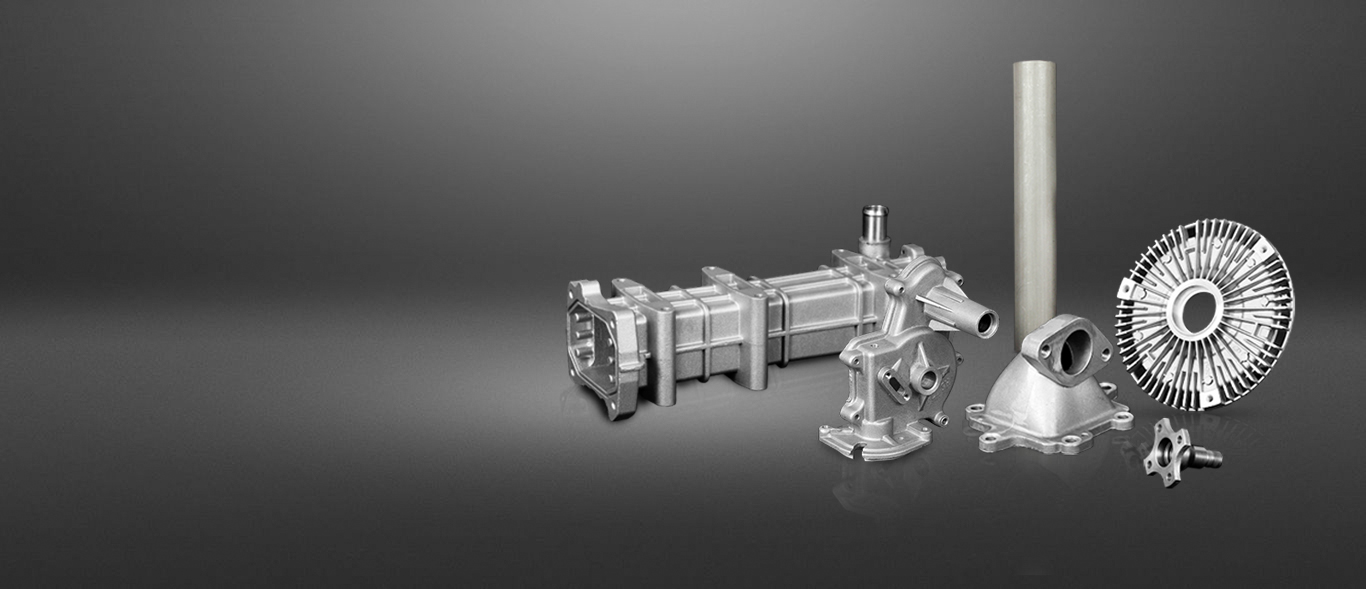

Product Portfolio

We have a team of skilled die casting engineers who are experts when it comes to right utilization of high pressure die casting to produce intricate castings.

The Cross Functional team takes care of the complete Process of Project Management right from defining the project and targets, till the final PSW Submission. A close interaction is maintained with the customer throughout the development process. Process Development is the key to ensure timely identification and deployment of all the necessary resources not only in terms of machines but also inspection facilities, trained manpower, utilities etc to ensure smooth development, trial, inspection and submssion of PPAP lots as per defined time lines.

Read More

We Cast Your Design

We Cast Your Design Quality in every aspect of business

Quality in every aspect of business Technology Meets Workmanship

Technology Meets Workmanship