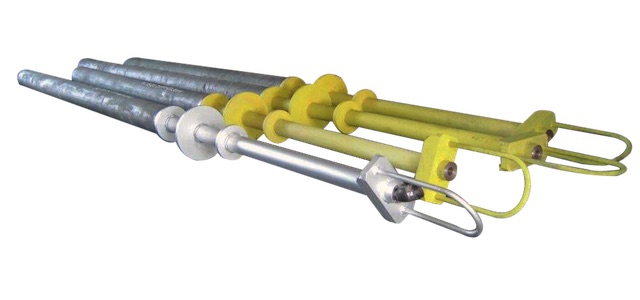

Refractory / Monolithic Injection Lance

Refractory Injection Lance, offered by us is widely used in varied steel industries for strength and performance. Composite constructions is available in thermally stable and slag resistant vibrocast refractory materials having high density, strength and structural integrity with divergent outlets.

We CUSTOMISE REFRACTORY INJECTION LANCE DESIGN keeping in mind the requirements of various clients.

The TOP REFRACTORY MONOLITHIC LANCE technology integrates a variety of functions which expands the metallurgical and operational capabilities.

FOLLOWING MEDIA CAN BE BLOWN:

- Decarburization at high initial Carbon level

- CO post combustion

- Chemical heating of liquid steel by aluminothermic reaction

Gaseous Fuels (Nitrogen, Argon, Oxygen etc.) for :

- Refining / Homogenisation of liquid steel

- Compensation of thermal loss

Metallurgical Power (Lime, Alumina, Synthetic Slag, Iron oxide) for:

- Desulfurizaion

- Decarburization

- Provides various additional functions

- Extended metallurgical degree of freedom

- Reduced temperature loss of steel

- Extended refractory lifetime

- Improved plant availability

- Improved sequence casting capability

- Pig Iron Desulphurisation

- Gas Injection / purging for homogenization

- Powder injection e.g. – coke, calcium silicide.

- Ideal distribution of alloy and deoxydation reagents

- Improvement in purity of steel

Salient Features

- Tailor made to suit customer’s requierments

- Composite construction available in thermally stable & slag resistant material

- Vibrocast material with high density, strength and structural integrity

- Available with divergent outlets