Filter Media & Fine Filtrations

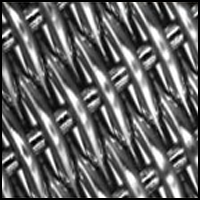

Plain Dutch Weave(PDW) Filter Mesh

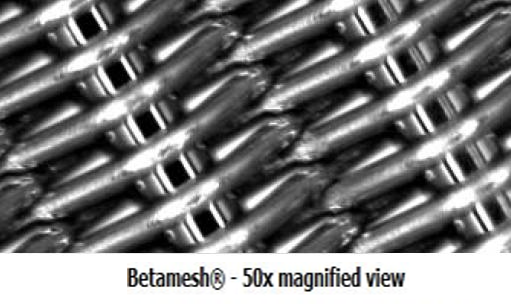

Our organization is amongst the prominent manufacturers and suppliers that offer an extensive range of Betamesh. The Betamesh is a woven wire filter cloth that exposes modern flow and dirt removal abilities. These are extensively used with the liquid propulsion systems, oil and fuel systems where enhanced dirt removal and flow capabilities are crucial. The offered range of Betamesh is helpful in protecting the steering, fuel injection jets and bearings. Moreover, these BOPP filter cloths are factory-made using latest production equipment in accordance to high quality standards under the clean-room conditions.

Horizontal Pressure

Leaf Filter- Plates

Horizontal Pressure

Leaf Filter- Plates Plain Dutch Weave -

50 Magnified view

Plain Dutch Weave -

50 Magnified view  Oil filter made from

BOPP TDW mesh

Oil filter made from

BOPP TDW meshBetamesh

Our organization is amongst the prominent manufacturers and suppliers that offer an extensive range of Betamesh. The Betamesh is a woven wire filter cloth that exposes modern flow and dirt removal abilities. These are extensively used with the liquid propulsion systems, oil and fuel systems where enhanced dirt removal and flow capabilities are crucial. The offered range of Betamesh is helpful in protecting the steering, fuel injection jets and bearings. Moreover, these BOPP filter cloths are factory-made using latest production equipment in accordance to high quality standards under the clean-room conditions.

Specifications:

| Absolute filter rating µm | Mesh description | Yield strength (warp/weft) Rp N/cm | Pores count N Pores/cm2 | Porosity % | A0rel % | Weight kg / m2 | Thickness mm | ||

| 15 - 17 | Betamesh 15 | 55 / 70 | 75'300 | 65 | 22 | 0.25 | 0.09 | ||

| 18 - 22 | Betamesh 20 | 70 / 90 | 52'200 | 64 | 27 | 0.32 | 0.11 | ||

| 22 - 26 | Betamesh 25 | 95 / 100 | 38'000 | 64 | 31 | 0.37 | 0.13 | ||

| 27 - 31 | Betamesh 30 | 110 / 110 | 28'200 | 64 | 33 | 0.45 | 0.15 | ||

| 30 - 34 | Betamesh 35 | 130 / 120 | 21'200 | 64 | 33 | 0.51 | 0.17 | ||

| 34 - 38 | Betamesh 40 | 140 / 140 | 16'300 | 65 | 34 | 0.57 | 0.20 | ||

| 42 - 48 | Betamesh 50 | 190 / 190 | 10'900 | 64 | 35 | 0.72 | 0.25 | ||

| 52 - 58 | Betamesh 60 | 210 / 230 | 7'400 | 65 | 34 | 0.86 | 0.30 | ||

| 66 - 74 | Betamesh 75 | 280 / 240 | 4'600 | 64 | 34 | 1.11 | 0.38 | ||

| 81 - 89 | Betamesh 90 | 330 / 320 | 3'200 | 65 | 33 | 1.31 | 0.46 | ||

| 25 | Betamesh R 25 | 75 / 210 | 29.100 | 0.23 | 0.62 | 55 | 24 | 0.68 | 0.19 |

| 34 | Betamesh R 34 | 90 / 210 | 20.900 | 0.29 | 0.65 | 56 | 32 | 0.75 | 0.22 |

| 48 | Betamesh R 48 | 110 / 180 | 11.200 | 0.38 | 0.53 | 63 | 35 | 0.73 | 0.25 |

| 60 | Betamesh R 60 | 170 / 175 | 6.700 | 0.49 | 0.50 | 66 | 20 | 0.79 | 0.30 |

| 80 | Betamesh R 80 | 180 / 220 | 3.800 | 0.65 | 0.79 | 64 | 32 | 1.15 | 0.42 |

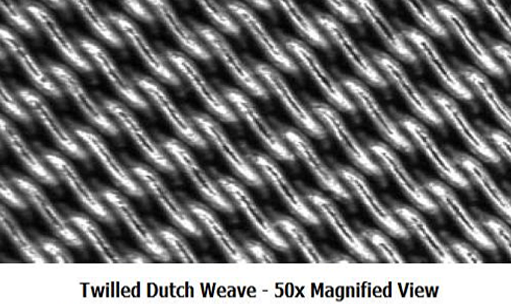

Twilled Dutch Weave

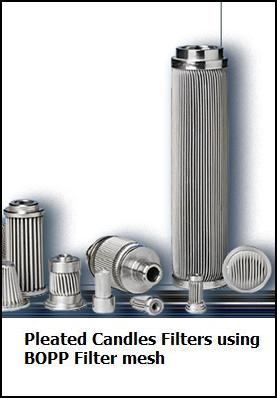

We offer to our customers a wide range of Twilled Dutch Weaves, which attains the smallest monofilament filter pores along with a smooth mesh surface. Advanced mesh stability is accomplished with the help of a large material cross section. The mesh is used for attaining fine filtration at fine specifications like fuel filtration in critical applications, pressure filtration in hydraulic steering applications and candle filters.

The meshes are manufactured using BOPP material, which is used in alloys, metallic material, woven wire filter cloths and stainless steel. Further, the BOPP filter cloths are manufactured with the help of advanced production equipment under clean room conditions.

Specifications:

| Absolute filter rating µm | Nominal filter rating µm | Mesh description | Yield strength (warp/weft) Rp N/cm | Pores count N Pores/cm2 | AsK mm2/cm | AsS mm2/cm | Porosity % | A0rel % | Weight kg / m2 | Thickness mm |

| 5 - 6 | < 1 | 510 x 3600 | 40 / 100 | 142'000 | 0.10 | 0.25 | 35 | 5 | 0.28 | 0.05 |

| 6 - 7 | < 1 | 450 x 2750 | 35 / 140 | 94'000 | 0.09 | 0.33 | 33 | 4 | 0.35 | 0.06 |

| 7 - 8 | 1 | 375 x 2300 | 60 / 160 | 63'000 | 0.12 | 0.42 | 33 | 4 | 0.46 | 0.08 |

| 8 - 9 | 2 | 325 x 2300 | 65 / 160 | 54'000 | 0.15 | 0.42 | 34 | 4 | 0.46 | 0.08 |

| 9 - 10 | 3 | 325 x 1900 | 65 / 170 | 45'000 | 0.13 | 0.50 | 32 | 5 | 0.54 | 0.09 |

| 11 - 12 | 4 | 250 x 1400 | 130 / 230 | 26'000 | 0.24 | 0.67 | 31 | 4 | 0.76 | 0.13 |

| 12 - 14 | 5 | 200 x 1400 | 140 / 230 | 21'000 | 0.30 | 0.67 | 33 | 4 | 0.81 | 0.15 |

| 16 - 18 | 10 | 165 x 1400 | 130 / 230 | 17'000 | 0.25 | 0.67 | 37 | 6 | 0.76 | 0.15 |

| 24 - 26 | 15 | *165 x 800 | 130 / 270 | 10'200 | 0.25 | 0.67 | 46 | 8 | 0.74 | 0.17 |

| 28 - 32 | 20 | *200 x 600 | 110 / 150 | 9'300 | 0.22 | 0.38 | 59 | 9 | 0.48 | 0.15 |

| 35 - 38 | 25 | 80 x 700 | 130 / 480 | 4'500 | 0.25 | 1.25 | 38 | 7 | 1.18 | 0.25 |

| 70 - 75 | 50 | 40 x 560 | 200 / 600 | 1'700 | 0.40 | 1.67 | 44 | 11 | 1.72 | 0.38 |

| 90 - 100 | 80 | 30 x 360 | 280 / 900 | 840 | 0.58 | 2.50 | 42 | 9 | 2.49 | 0.55 |

| 110 - 120 | 100 | 20 x 250 | 180 / 1300 | 380 | 0.39 | 3.67 | 39 | 6 | 3.34 | 0.69 |

Sieving And Sizing Screens

BOPP-SI range covers our comprehensive selection of precision woven wire meshes developed specifically for sieving and sizing in pharmaceutical and chemical industries. BOPP-SI wire meshes are produced in a clean, air conditioned environment by skilled craftsmen on state of the art looms. Rigorous quality control procedures guarantee an excellent product every time.

Applications:

Wet and dry sieving equipment, vibro sifters and eddy current sieving for the production and extraction of:

- Chemical products

- Foodstuffs and spices (milk powder, coffee, tea, rice, grains)

- Stones and powders (minerals, diamond sizing, ores, alumina)

- Pharmaceutical products

- Boards and fixing plates (dividing shavings and wadding)

- Paper (sieving wood shavings, preparation of coatings)

- Metal powders (Precision sieving of metal powders)

- Rubber

- Animal feedstuffs (dedusting pellets, sieving crumbs, molasses based foodstuffs)

- Fertilisers (phosphates, potash, urea, mixed fertilisers)

- Sugar and salt (sizing)

- Recycling

- Many others

Properties:

- Accuracy of weave

- Regularity in

- High stability & tension tolerance

- Rigid and resistant to elongation or pore change

- Corrosion resistant, with superior quality of Stainless Steel wires used

- Thermal resistance

- Resistance to moisture

- No static loading

- Ease of fabrication (flat lying, no curl)

Specifications:

BOPP SI mesh is available in the range 20 micron – 16 mm apertures in Stainless Steel AISI 304.

Note: Test Quality Sieves are also available on request.

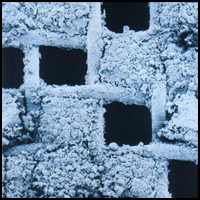

Sieving Screen

Sieving Screen Magnified View

Magnified View Vibro sifter Screen

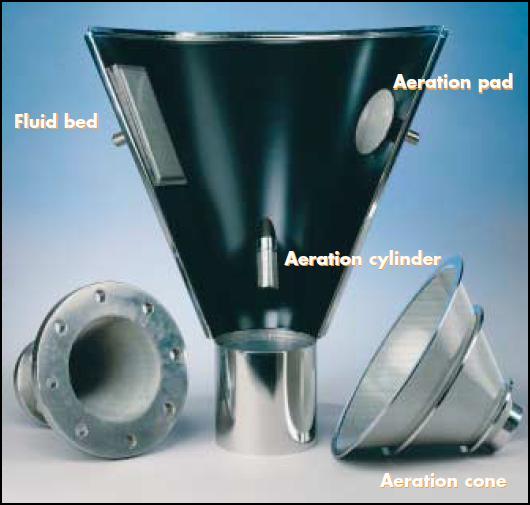

Vibro sifter Screen Aeration Pads

We have gained the expertise in manufacturing a wide range of Aeration Pads, which is best suited for transporting and fluidizing of powdered bulk goods. These are manufactured into aeration pistols, mushrooms and cushions. The pads are also suitable for retrofit into outflow and sidewall areas of silos. With the help of selective aeration the promotion can be continuous that results into loosening of bulk goods. Our pads are made from Poreflo® an extremely robust filter medium for use under mechanical load. Despite its high levels of rigidity, it is easily fabricated into different shapes.

Specifications Available:

Poreflo® is available in 5- 50 micron ratings in Stainless Steel 316 L material and may be fabricated to custom sizes such as cylindrical, conical, circular or rectangular pads, etc. as per the target vessel.

Chromatography Frits

We are a well known manufacturer and supplier of an extensive range of Chromatography Frits. Our organization offers Absolta and Poremet, which are idealistic mediums for Chromatography frits and distribution plates. These types of multilayer sintered filter mesh are manufactured in different layers such as 5 layers having the thickness of 1.7mm and 20 layers having the thickness of 5mm.

Specifications:

- Material used: Stainless steel (including 316L), Titanium, Hastelloy® Alloy C-22

- Sizes : 10mm to 1200 mm diameter

Features:

- Uniform porosity

- Clean-ability

- High flow rates

- Ability to withstand high pressures

Gas Spargers

Our organization has been supplying a quality range of Gas Spargers. These are manufactured using Poreflo and Poremet that exhibit a superior property of uniform distribution. The spargers have the capability to control very low pressure drop (0.005 bar) and also the high flow rates with gases and air. Due to their perfect functioning these find application in sparing of gases, aeration and de-aeration as an active pharmaceutical ingredients.

Superior quality raw material such as Poreflo® and Poremet (available in 5- 50 micron) and Stainless Steel 316 L material is used for manufacturing to ensure the high standard of the range. We also offer customization and manufacture the spargers as per the size and shape specified by the clients.

Cylindrical Gas Spargers

Cylindrical Gas Spargers Cylindrical Gas Spargers

Cylindrical Gas Spargers Ciecular/Flat aeration pads

Ciecular/Flat aeration pads Multilayer Sintered Filter Media

Our customers can avail from us an innovative printing solution as Multilayer Sintered Filter Media. Sintering is a process in which an enhanced woven wire cloth depends upon a molecular diffusion-bonding. This laminates the multiple layers of wire cloth and creates a diverse and highly useful class of permeable material, which is also termed as Multilayer Sintered Wire Mesh/ Filter Media. These discs find their application in different applications.

We offer two standard kinds of sintered filter mesh to our clients such as Poremet, which determines the filtration of highly viscous fluids with Agitated / Non-Agitated Nutsch Filters & Dryers (ANFD), pressure filtration and centrifuges. Moreover, we also offer Absolta, which is widely used in liquid and gas filtration in order to attain optimum flow and backwash capabilities with the Agitated / Non-Agitated Nutsch Filters & Dryers.

Specifications:

| Specification | Poremet | Absolta |

| Micron Range | 1-100 | 1-100 |

| No. of layers possible | 5-20 | 3-20 |

| Material | SS 316 L , Hastelloy C-22 | SS 316 L , Hastelloy C-22 |

| Sizes (mm) | OD 10-2000mm | OD 10-2000mm |

Candle filter & fine filteration

Candle filter & fine filteration Poremet Five layer Construction

Poremet Five layer Construction  Absolta five layer construction

Absolta five layer construction Nutsche Filter Plates

We have earned a position of repute in manufacturing an extensive range of Nutsche Filter Dryers, which is best suited for processing ultra high purity and pharmaceutical material. The dryers require a rugged filter medium to resist the harsh dynamic operating conditions. The filter dryers are well appreciated for their portability and multi-application versatility.

Advantages:

- Very high mechanical strength

- Structural Integrity

- Uniform Pore size

- Excellent clean ability suited for sterile products

- Easy to fabricate

In addition to this, we are experts in the welding of Absolta and Poremet filter discs with the supporting ring, down-holders and refurbishing damaged plates of Agitated Nutsche Filter Dryers.

KUMAR ENTERPRISES

Corporate and Regd. Office :- A-9, Kumar Classics, Aundh, Pune - 411 007 (India)

Phone No : +(91) - 020 - 2588 1704 , Fax No : +(91) - 020 - 2588 0851

Email : kks@pn2.vsnl.net.in / info@kumarenterprises.com

TECHNOLOGY PARTNERS

ASSOCIATE BUSINESS