IR Process Heaters

Krelus IR Heater

The fast medium wave KRELUS IR-heaters are superior to most other heating systems, due to medium-wave radiation in the range of 2,5 µm - 3,5 µm which gets the best results. KRELUS-IR-heaters are working with the shortest reaction time ON/OFF. This guarantees the highest economical use of electrical energy and fastest adaption to required temperatures on product surfaces.

Properties:

- highest energy efficiency

- fast respond ON/OFF

- no increased start-up current

- medium wave energy in the best absorption range 2.6 µm - 9.6 µm

- maximum achievable temperature 8500c

- maximum wattage upto 50 kw/m2 (5 w/cm2)

- full surface area heating / radiating

- modular design of heaters can be joined together

- separate heating zones possible

- operating voltages from 10 Volt to 660 Volt

- fully controllable

Applications:

- Fabric & Synthetic pre-heating or drying

- Coating of plastic, textile, paper, etc.

- thermoforming

- activation of glue

- lamination

- melting of plastic powder

- curing of plastics (gelification)

- preheating before embossing

- welding of car parts (also in 3D)

Maintenance

There is virtually no maintenance required as there are no moving parts. Any necessary replacement of the spares can be accomplished by customers’ own personnel. An instruction manual is supplied.

Spares

Heater Foils incl. Clips and Tools, Support, Insulating Plates, etc. can be ordered for, as and when need replacement.

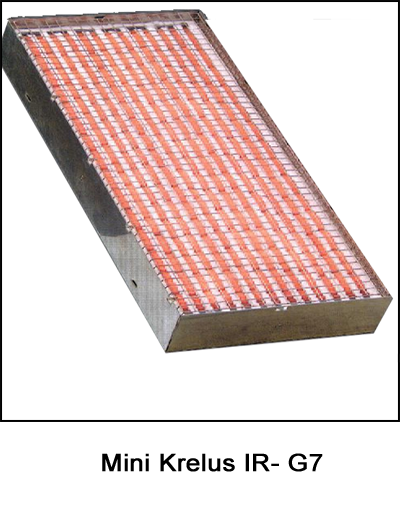

Krelus Mini

\

The KRELUS-MINI-IR-heaters combine all the advantages of more than 20 years experience with KRELUS INFRARED techniques. KRELUS-MINI-IR heaters are available in two sizes. These sizes are 248 x 248 mm and 123 x 496 mm. These offer uniform setting, edge zone setting, individual setting for a modular heating system.

Unique Advantages:

• short reaction

ON ~ 10 s / OFF ~ 2 s

• high intensity

20 kW/m2, 26 kW/m2 and 32kW/m2

• easy control continuously

20°C – 800°C

• modular sizes

Electronic Control Cabinet

The electronic control allows the output of the heaters to be regulated continuously on the following principles:

The electronic control allows the output of the heaters to be regulated continuously on the following principles:

• manually by potentiometer

• measuring temperature using a probe

• optical pyrometer

• measurement of humidity using a probe

• machine speed, etc.

KUMAR ENTERPRISES

Corporate and Regd. Office :- A-9, Kumar Classics, Aundh, Pune - 411 007 (India)

Phone No : +(91) - 020 - 2588 1704 , Fax No : +(91) - 020 - 2588 0851

Email : kks@pn2.vsnl.net.in / info@kumarenterprises.com

TECHNOLOGY PARTNERS

ASSOCIATE BUSINESS