Infrared lamps are basically heater lamps, working on the principle of infrared radiation heating. It is direct and non-contact method for object heating where energy is transmitted by electromagnetic radiation. Depending on the absorption factor, the object can absorb up to 91% of the radiated energy, which gets transformed into heat. Normally, full efficiency is achieved within 1-3 seconds. With infrared heating systems, space requirements reduce drastically.

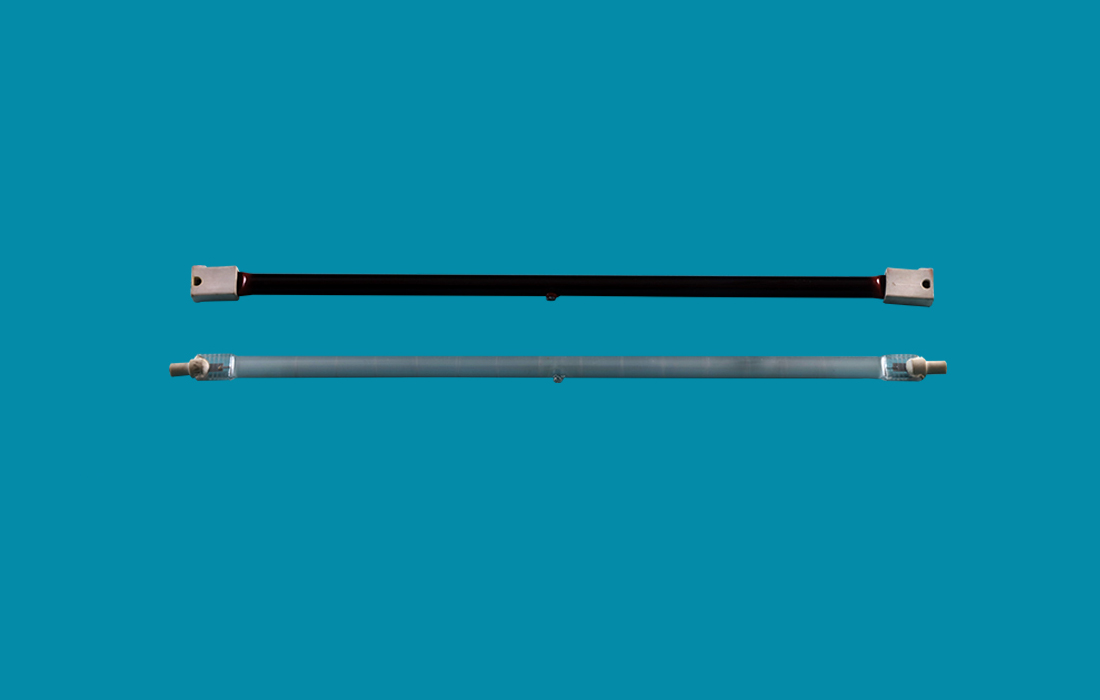

Infrared Halogen Lamps are “bright emitters” as; part of the energy that is emitted is in the form of light. These lamps convert 84% of the electrical energy into Infrared radiation.

- Instant on

- Upto 91% energy conversion

- Long life

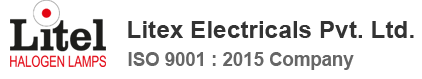

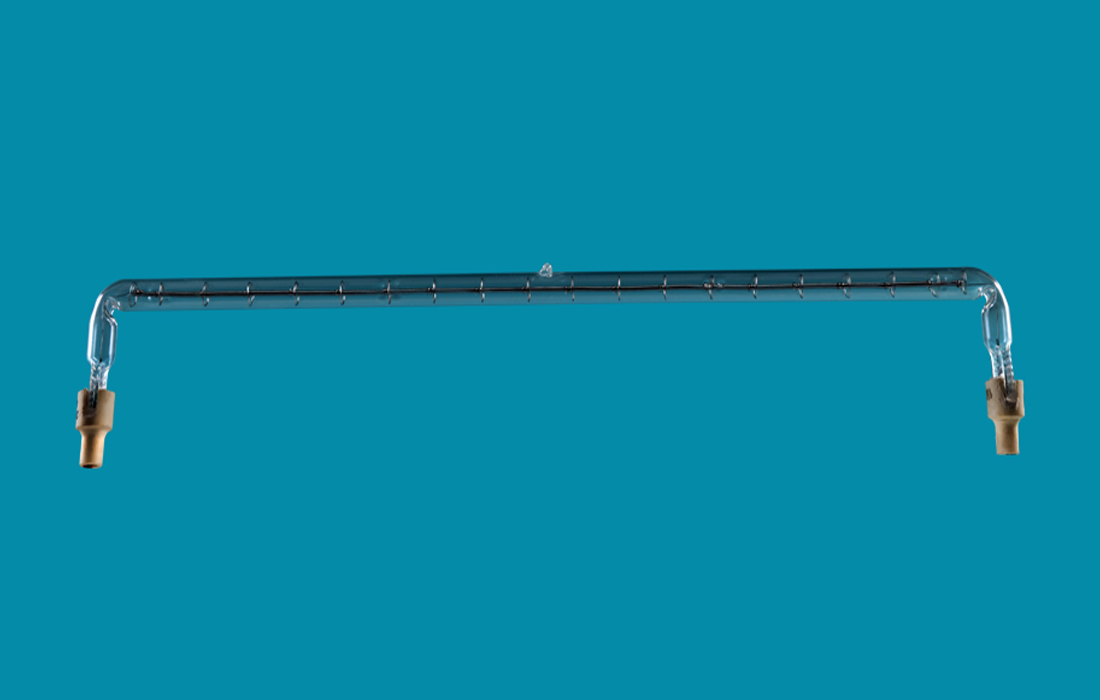

- Robust design

- Dimmable

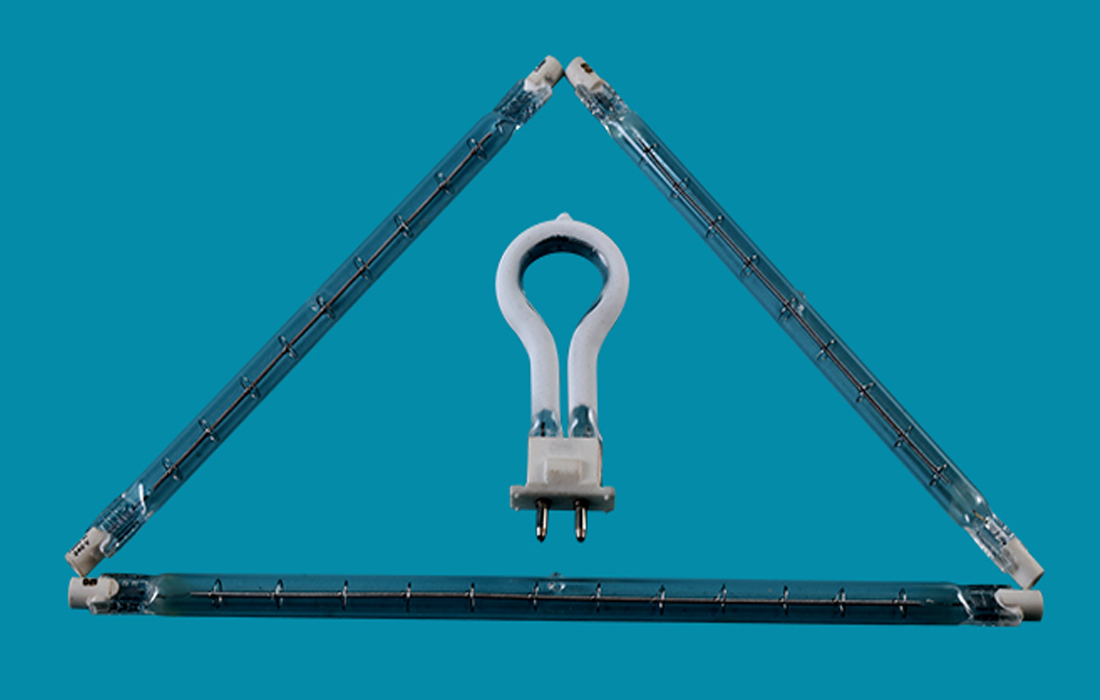

- Compact construction

- Ability to control

- Ability to direct

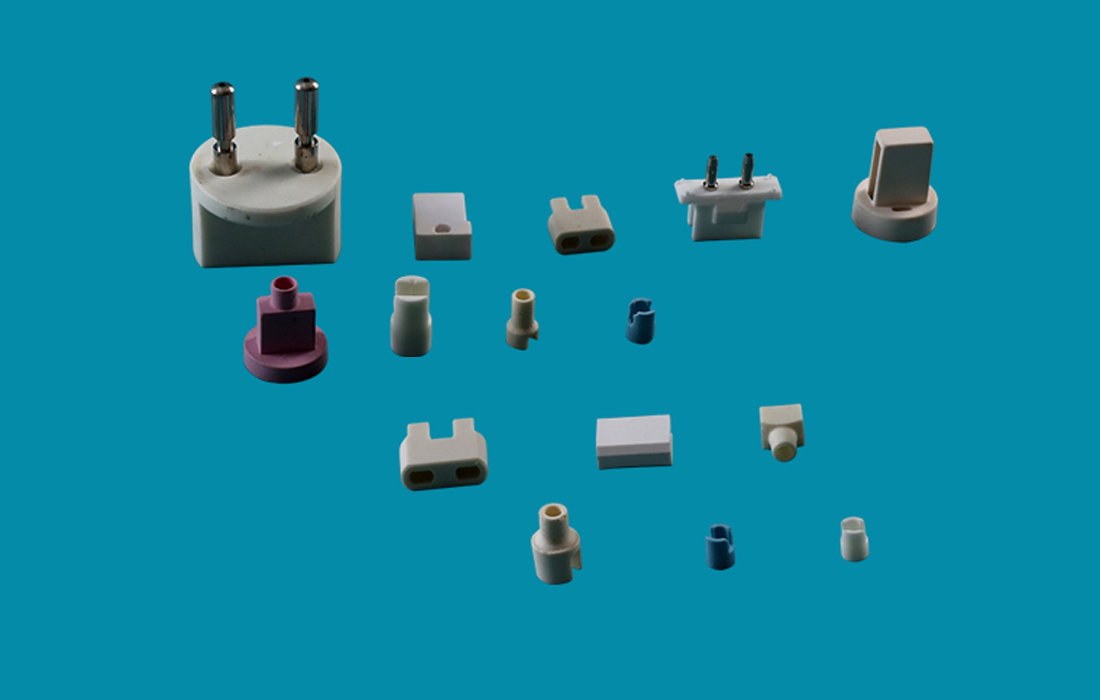

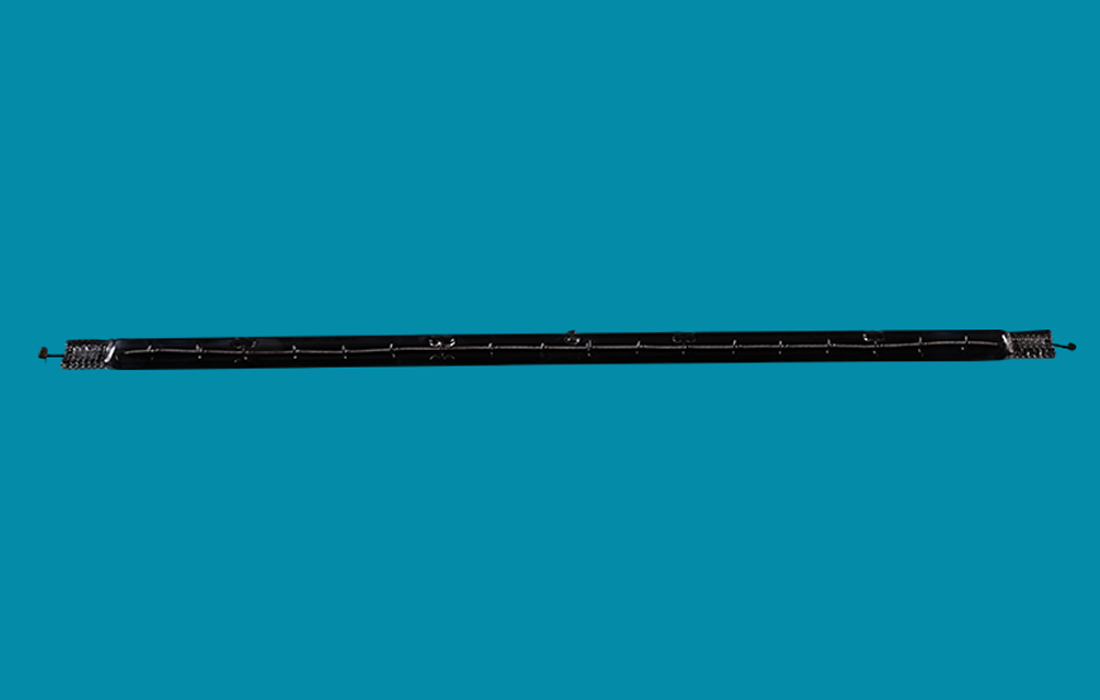

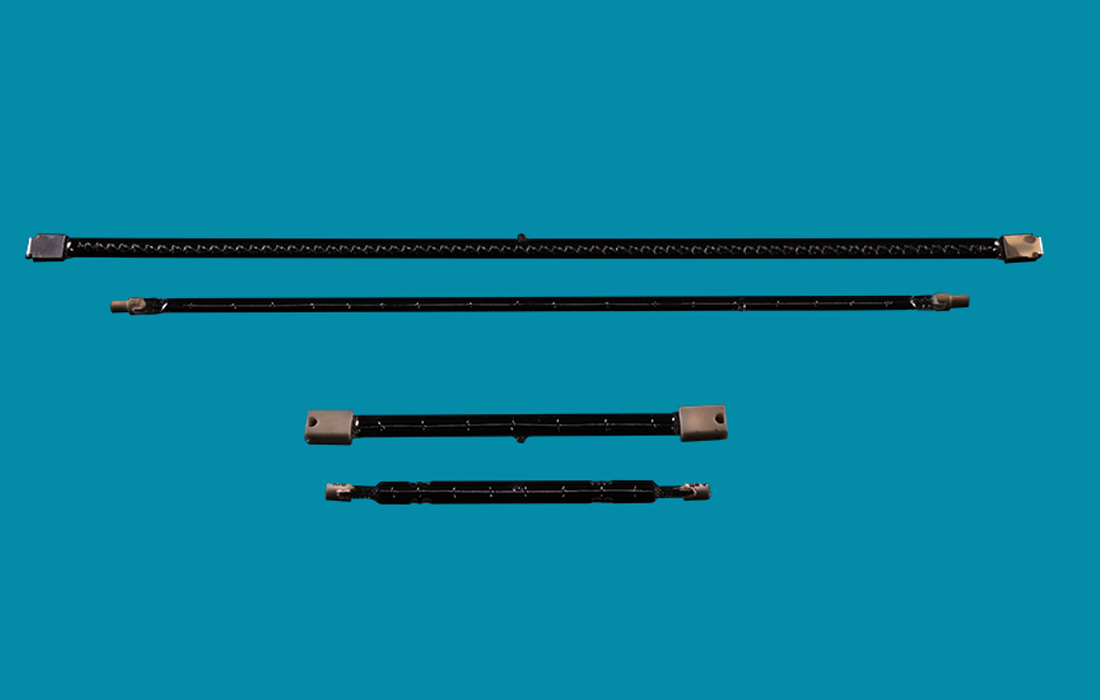

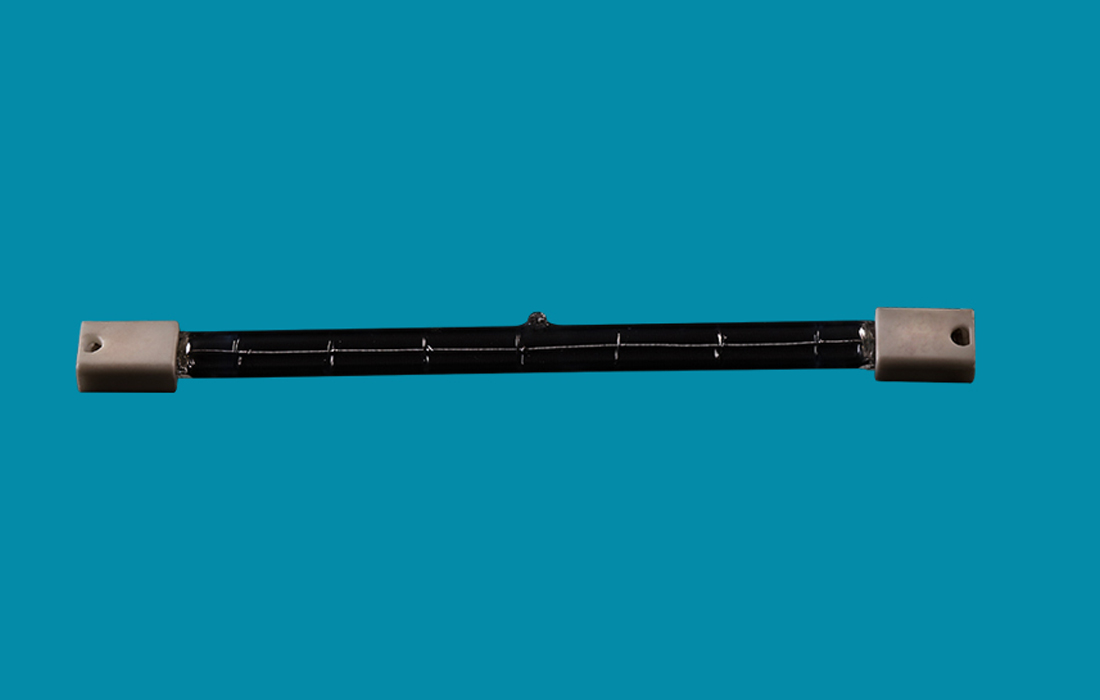

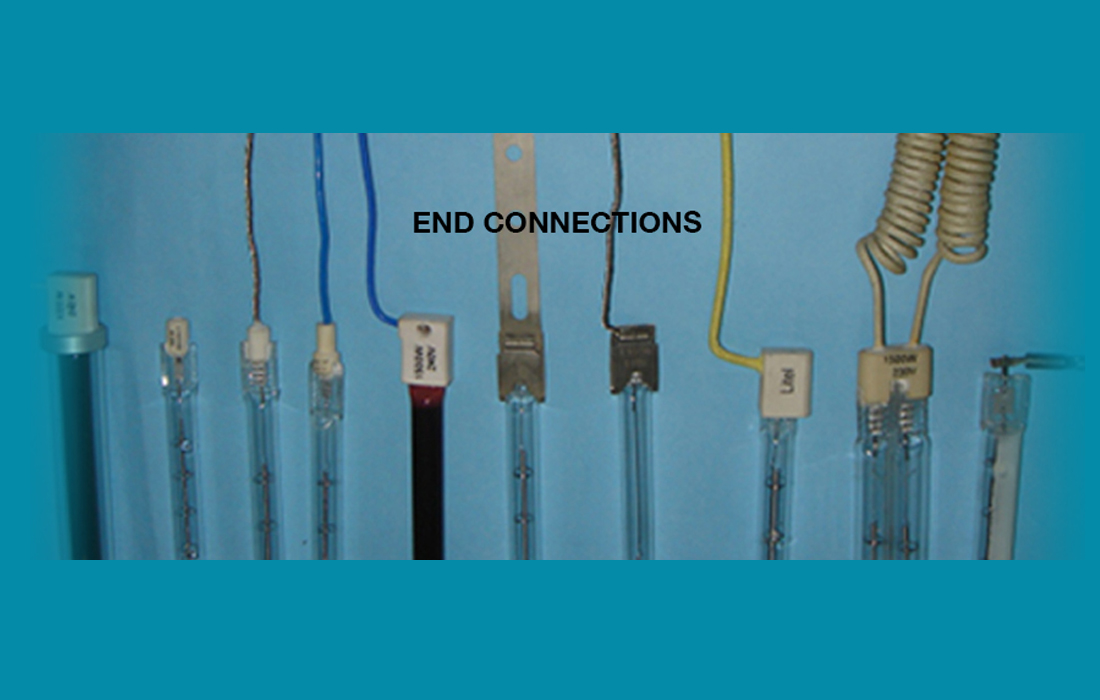

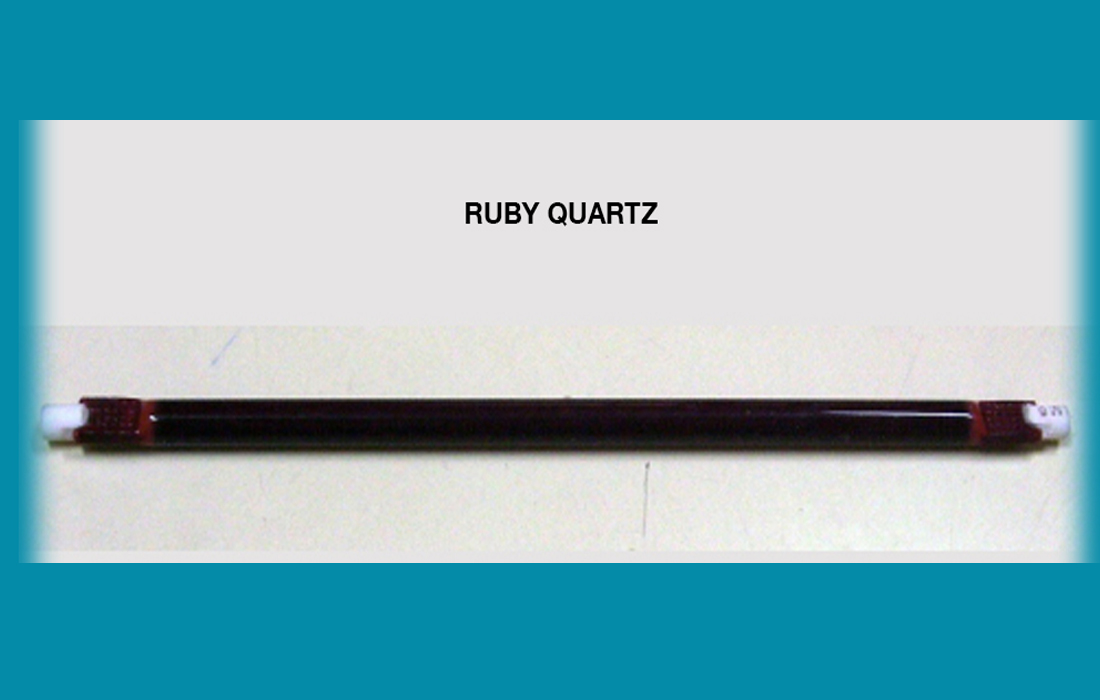

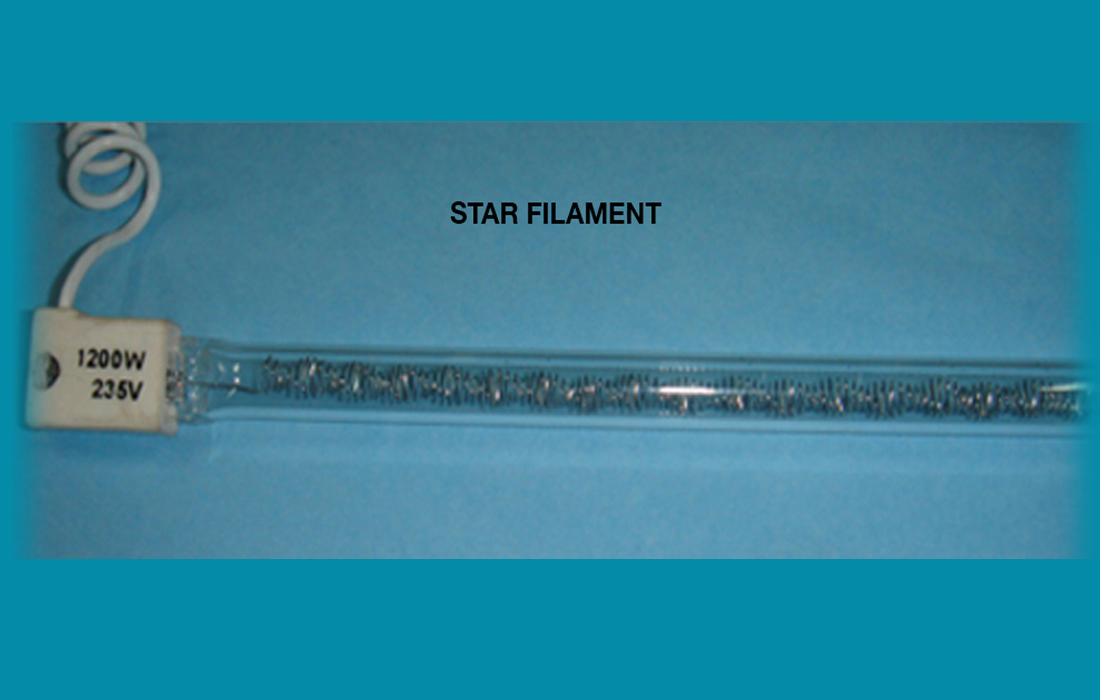

We, at Litex can manufacture these lamps in variety of wattages, lengths, reflector coatings and connections, as per your requirement.