Folding technology offers a new dimension to sheet metal bending. It provides high flexibility to fold variety of parts without changing tools or machine adjustment. Sheet remains flat on the machine while bending so the operator does not have to support the sheet. It is a very safe and fatigueless operation for the operator. The folding beam swings to fold the sheet, bends can be made from any angle without changing the tooling hence reducing setup cost as well.

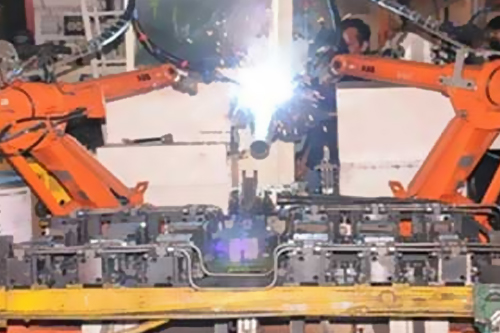

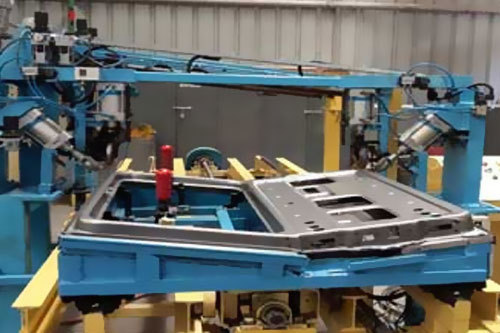

Robot welding is the use of mechanised programmable tools (robots), which completely automate a welding process by both performing the weld and handling the part.

Roll forming, is a type of rolling involving the continuous bending of a long strip of sheet metal (typically coiled steel) into a desired cross-section.

Powder coating is the process of applying dry paint to a part. In comparison to normal wet painting such as house paints, the solids are in suspension in a liquid carrier, which must evaporate before the solid paint coating is produced.

Rolled spot welding is a kind of resistance welding and is derived directly from spot welding. The electrodes are designed as copper rollers. The rollers above and below the sheets to be welded press the sheets together and simultaneously transfer the weld current. Different spot geometries are possible, unlike spot welding, roller seam welding is a continuous process – at least as far as the relative motion of electrode and workpiece is concerned. The rollers run along the sheet and do not have to be opened for the feed process. For the same reason, wear on the electrodes is reduced. The weld spots are generated by means of current pulses.

Mungi Group will soon be equipped with an R&D centre along with a commercial tool room. It will be located at Chakan, Pune and will primarily focus on the research and development of new technologies and advanced processes.

This process increases efficiency and productivity on the shop floor. It ensures that, to make one part only one tool is required rather than traditional method where multiple tools are used. This will reduce capex cost, tool inventory as well as tool loading and unloading time.

Clinching also referred as "Press-Joining" is a bulk-sheet metal-forming process aimed at joining thin metal sheet without additional components, using special tools to plastically form an interlock between two or more sheets.

Today’s robots, with improved accuracy and calibration methods, permit exceptional off-line programming of cutting paths. Six-axis robots provide the flexibility and precision required for cutting applications. To date, this might have been considered a niche market when compared to 2D sheet cutters, however robots provide unique capabilities for part recognition through vision, six degrees of freedom for bevel control, and for part load and unload. Direct or point-to- point teaching is an effective programming method when fine tuning or adjustments are required. HiFocus series achieve highest cutting quality and are, therefore, a serious alternative to laser cutting or other precision cutting methods.The HiFocus 161i neo is the latest high-precision plasma cutting system for the cutting range between 0.5 mm and 50 mm.