Multi mill is widely used for wet and dry granulation, pulverization etc. of pharmaceutical, chemical, bulk drug, cosmetic, colours, dyestuffs. food products etc.

Multi mill is widely used for wet and dry granulation, pulverization etc. of pharmaceutical, chemical, bulk drug, cosmetic, colours, dyestuffs. food products etc.

Description

The unit consists of stainless steel hopper, processing chamber with beater assembly, motor, DOL starter, three speed pulley, screen and sturdy body.

Operation

SS beaters having knife and impact edges rotate within a selected screen. The material fed in the hopper enters into the processing chamber where it moves to the pentery and passes through screen. Output & quality of final products depends on (I) shapes of beaters (Knife/ impact edge) (ii) speed (iii) size of screen.

Salient Features

• All contact parts SS 304/ SS 316. available in standard and GMP model.

• Direction of beaters can be changed by reversible switch from knife to impact toward and vice versa.

• All contact parts can be easily and quickly dismantled for cleaning.

• Machine is designed for continuous operation. Castors are provided for mobility of the machine

• flame proof electricals can be provided at extra cost.

• Beaters and scraper blades are hardened and hard chrome plated.

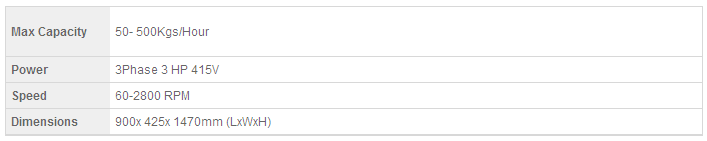

Technical specification

Description

Description

Vibro sifters are circular gyratory screens used to separate mass composition of solids, liquid from solid and for gradation of materials as per particle sizes

Construction Details

Machine provided with specially designed rubber coupling unit providing adjustable vibrations. All contact parts of SS 304 quality complete unit is mounted on MS frame duly SS claded with proper bushing and fitted on castor wheels. The machine is powered by 1.5 HP 1440 RPM electric motor.

Salient Features

• Available in standard and GMP models with contact parts in stainless steel 304 or 316 quality.

• Portable unit with higher output.

• Double and triple deck unit with different screens can be provided.

• Easy to dismantle for cleaning screens.

• Noiseless, maintenance free unit.

Construction Details

Construction Details

Machine provided with specially designed rubber coupling unit providing adjustable vibrations. All contact parts of SS 304 quality complete unit is mounted on MS frame duly SS claded with proper bushing and fitted on castor wheels. The machine is powered by 1.5 HP 1440 RPM electric motor.

Features

• More Vibrations.

• Easy to operate and clean.

• Different mesh sizes available.

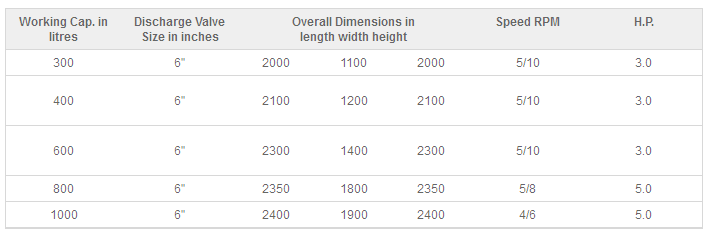

Technical specification

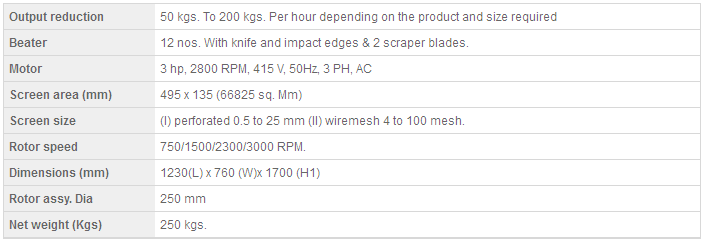

Description

Description

Tablet coating pan is used for sugar and film coating of tablets, pallets, granules etc

Construction

It consists of ellipsoidal shaped pan made of stainless steel sheet and mounted on the gear box shaft which is driven by an electric motor. The complete drive unit is enclosed in a sturdy cabinet. Hot air blower with SS Pipe heaters is provided with thermostat control for fast drying. Heaters are interlocked with the blower motor therefore unless the blower is on, heater does not start. Available in Standard and GMP model with SS 304 or 316 contact parts.

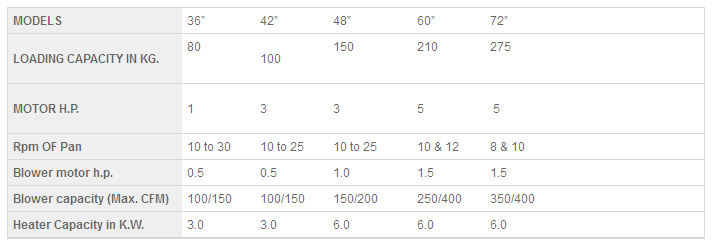

Technical Specification

Description

Description

Dust extractor is used for controlling dust generated during tablet compression, tablet de-dusting, granulation and other processes. It avoids product cross contamination.

Features

• All contact parts in SS 304/ SS 316 quality.

• Machine is provided with castor wheels.

• Nos. of manifold to connect two or three machines at a time.

• Easy Cleaning.

• Dynamically balanced air blowing fan.

• Storage capacity of 3 / 4 CU ft.

• Suction capacity of 200/300 CFM.

Description

Description

Tray Dryer is used for the best drying results in conventional process. Construction Detail- It is a double walled cabinet with one or two doors. The gap between two walls is filled with high density fibre glass wool insulation material to avoid heat transfer. Doors are provided with gaskets. Stainless steel trays are placed on the movable trolleys.

Dynamically balanced axial flow type blower fans are provided for uniform air circulation in the drying chamber during process. Machine is provided with control panel board with process timer. Digital temperature controller cum indicator etc.

Capacity

• 24, 48, 96 Trays.

• Standard and GMP models available with SS 304/ SS 316/ MS internals and externals

• Stainless steel tray in S.S. 304/ S.S. 316 quality

Salient Features

• All stainless steel 304 / 316/ 316L .

• Electric / Steam Heating .

• Minimum Heat Loss.

• Uniform temperature.

• Control panel board with process timer.

• Sturdy trolleys with castor wheels. Air filter at inlet.

• Easy accessibility of impellers for cleaning .

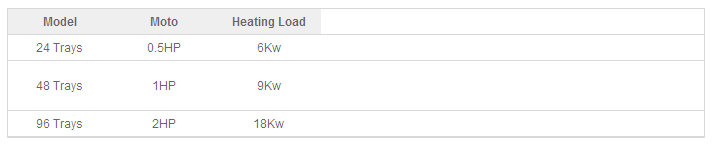

Technical specification

Description

Description

Fluid bed dryer is most suitable for pharma equipment and can be used in chemical, food, dyestuff, and polymer industries for fast and efficient drying. All contact parts are made out of stainless steel 304 / S.S. 316 quality and control panel is provided with the machine.

Operation

due to induced draft created by specially designed heavy duty fan, the atmospheric air is drawn through air filter. The filtered air is then heated to the required temperature by electric/ steam radiator. The hot air passes through the product container and the product gets dried by air fluidisation. The air circulation is controlled by damper. The filter bag prevents fine particles from carrying over to exhaust air stream.

Selection

selection of capacity of fluid bed dryer depends upon bulk density, drying temperature and moisture contents of wet material to be dried. In case of 120 kg. Model a batch of 145 kg. Wet material can be loaded provided the bulk density of the material is 0.6 kg./lit. (Approx). Pharmaceutical granules with 20-25% moisture can be dried in 30-45 minutes at 80 C approximately. This pharma equipment machine is provided with fully automatic control panel box with process timer, pneumatic finger bag shaking, pneumatic lifting of container, digital temperature controller cum indicator, voltmeter, ammeter, earthing system etc. Available in Standard and GMP model with SS 304 / SS 316 quality

Salient Features

• Better productivity and lesser drying time with less handling. More hygienic.

• Uniform drying at low temperature.

• Static grounders to eliminate electro static charges.

• SS Product container with trolley and tilting arrangement.

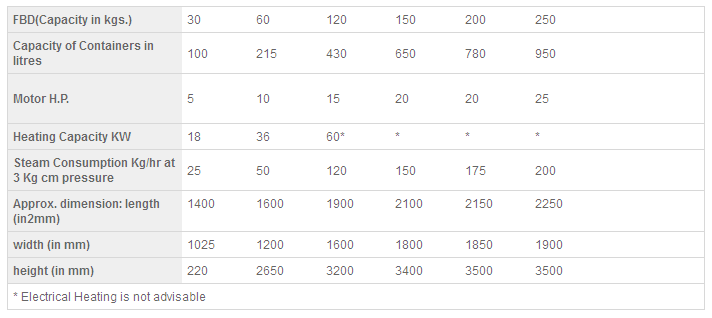

Technical specification

Description

Description

It is a very useful machinery for pharmaceutical industry where in gentle blending of dry granules or powder is to be done.

Construction

It consists of octagon shaped body, rectangular central portion and top and bottom polygonal frustum. It is provided with baffles for fast and efficient mixing, charging port and outlet with butterfly valve optional.

The entire unit is mounted on a sturdy stand, complete with electric motor and gear box. It can be supplied with bin charging system. The machine is provided with control panel board and safety railing.

Salient Features

• It is a slow speed blender and has a removable baffle mounted through a rectangular openable lid.

• Easy for cleaning in place.

• The power consumption is comparatively lower than the other similar type of blenders.

• Contact parts in limit switch is provided for operator's safety & manual intching arrangement.

• Flame- proof motors with flame- proof push button stations can be provided (optional).

Technical specification

Description

Description

For Gentle and Diffusive Blending of Dense Powders suitable for Blending of Large Batch Volumes in a short time.

Construction Details

Made from 14G. SS sheet having quick opening lid and mirror finish, running on heavy duty ball bearing driven by oil filled worm gear box and powered by suitable electric motor complete with starter and safety guard locks.

Features

• Easy and dustless operation.

• Model available 50 kgs. to 500 kgs. Cap.

• GMP / S.S.316 construction on demand.

• Mucon / butterfly valve provided for quick discharge for higher Cap. Model.

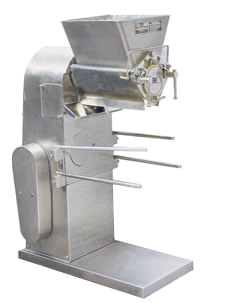

Description

Description

In tablet making, the process of granulation plays a vital role because the quality of the final tablet will depend on the quality of granules used for its compression. Most suitable for production of granules from wet and dry material. The quality of granules are better compared to other processing machineries such as Multi Mill, comminuting Mill. A unique Oscillatory rotor ensures high out put and efficient granulation .

Construction

The machine consists of a rotor with six hexagonal bars which oscillates at 60RPM, against perforated SS sieves forcing granules out. There is a quick opening arrangement for fixing perforated sieve with tightening device. Safety guard on the hopper is provided. All contact parts of the machine including front portion is made out of SS 304. Rotor can be easily removed for cleaning. The machine is driven by oil filled worm gear box and powered by suitable electric motor complete with starter and tray holder.

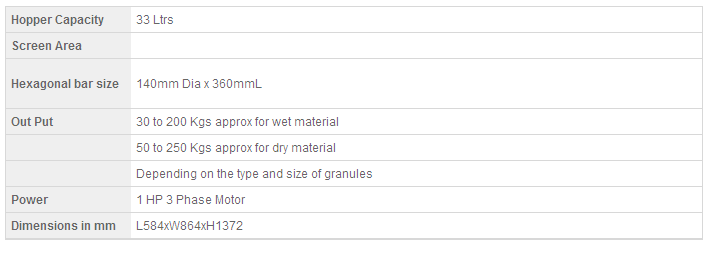

Technical specification

Description

Description

Most suitable for thorough mixing of dry or damp materials and is especially suitable for tablet granulation.

Construction

With all contact parts of SS 304/316. Shaft made from solid bar and SS pipe, 3/8” thick blade welded to the shaft and made as one piece. Shaft moving on ball bearing. Drum having two mechanical end seals (Tungsten Seal)to prevent the powder from going out and for oil sealing life long. Shaft driven by oil filled worm gearbox and powered by suitable motor. Machine having polycarbonate unbreakable sliding cover. Drum tilt able by hand for removing the material, complete with cover lock switch to stop the machine just on opening the plastic cover. Supplied with no volt coil starter.

Features

• Especially Designed Mechanical end seals to prevent black particles.

• No oil contamination.

• Unbreakable transparent polycarbonate lid.

Technical Specification

Description

Description

Suitable for visual inspection of tablets from both the sides.

Functional details

The tablets are fed in SS hopper and are delivered on a PVC running belt. The speed of feeding of tablet can be regulated by electronic regulator. The tablets are inspected on one side and automatically get reversed and travel on lower belt for inspection on the other side of the tablet. The rejected tablets are removed by hand and passed tablets falls in a container through a magnetic chute to hold any steel particle. Powered by suitable geared motor single Phase.

Features

• Special design requires much less space.

• Most Convenient for operator.

• Total SS body.

• PVC food grade endless belt giving much longer life.

Construction

Construction

Top feeding spiral vibrator with all contact parts of SS 316 quality powered by ¼ HP 1440 RPM vibro motor. Spiral assembly rested on three springs. The vibrations can be adjusted if desired with out much effort. Resting on SS platform on castors having height adjustment arrangement complete with starter.

Features

• Machine capacity 500-1000 tablets per min.

• All contact part of SS 304/316.

• Avoid tablet breakage problem.

• Easy to operate.

• More running path for tablets.

Starch Paste Kettle is designed as per good manufacturing practices in terms of cleanability of components, surface finished, absence of sharp corners, assembling and desembling of components and control devices. Machine can be design as per jacketed type, electrically or stream heated, thermostatic control with the unit, safety valve, insulated with suitable insulating material, tilting with hand wheel. Easy transfer of paste while tilting, unit will be provided with suitable lid, suitable discharge bottom valve for steam water, which should easily removable and easily cleanable.

Starch Paste Kettle is designed as per good manufacturing practices in terms of cleanability of components, surface finished, absence of sharp corners, assembling and desembling of components and control devices. Machine can be design as per jacketed type, electrically or stream heated, thermostatic control with the unit, safety valve, insulated with suitable insulating material, tilting with hand wheel. Easy transfer of paste while tilting, unit will be provided with suitable lid, suitable discharge bottom valve for steam water, which should easily removable and easily cleanable.

• Capacity - 50, 100, 200, 300, 500

Description

Description

The machine is widely used for sizing and uniform granulation as it is believed that better granulation leads to better end product of Tablet.

Working

The raw material is first poured into the grinding machine and separated by the cone shaped sieves. The rotating cutter stirs up the material in a swirling motion hence drawing the material towards the mesh or sieve by centrifugal force. The material is sized into small powder state and are ejected out of the pores of the sieve. The sizing is determined by the sieve size, the distance between the cutter and the sieve and the speed of the cutter which is controlled by VFD for variable speed. Powered by 3 Phase electric motor and direct coupled to the shaft to eliminate V belts hence complying to GMP norms.

Features

• Less dust, low heat, low noise, easy to clean, uniform pellet size, wide range of speed control.

• Ideally suited for material with high heat sensitivity, high moisture and stickiness.

Technical Specification