Description

Description

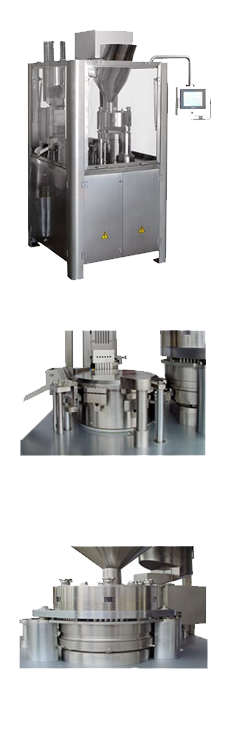

Integrating Machine, electrical and air, the machine is capable of doing separate operations like feeding, separation, filling and locking. The machine and working panel are made of SS which confirms to GMP standards. The light touch switches, feeding propeller and filling rotary table can be in automatic run based on preset and frequency speed control. Without traditional gearbox, it is simple in structure and easy to maintain. Complete with vacuum pump and air compressor. Comes with any one size of capsule change part.

Features

Automation of Loading station

This eliminates the need for continuous operator attention as control circuitry provides automatic

stoppage of loading table after completion of one cycle, each of 60 strokes.

Automation of filling Cycle

This feature eliminates the need for continuous operator attention. Pneumatic swing-in and

swing-back by the touch of a button of the drug hopper after one filling cycle results in reduced

operator fatigue.

Closing Station

This process is activated by a press of a paddle which activates a pneumatic cylinder to carry out the closing operation resulting in ease of operation and reduced operator fatigue.

Construction of machine

Overall construction of machine using S.S., aluminium, brass and mild steel with powder coating provides a high level of GMP.

Safety Inter lock

A safety interlock is provided on the guard for the loading section which provides operator safety.

Choice of variable speeds

A choice of variable speeds provides flexibility to achieve target weight. This is achieved by having variable frequency drives for both Auger and filling table.

Modular type hopper

The modular type hopper provides easy and fast dismantling for cleaning. Change over times between batches are reduced.

Auxiliary items

The machine is provided with a dedicated vaccum pump and air compressor.

All drive gears are sealed with four plexiglass doors inside the stand, which can keep away from the outside environment or better safety. All parts in contact with material in the chamber are made of stainless steel 316L, improving the quality of capsule and increasing convenience to change over installation with high accuracy and cleanliness

All drive gears are sealed with four plexiglass doors inside the stand, which can keep away from the outside environment or better safety. All parts in contact with material in the chamber are made of stainless steel 316L, improving the quality of capsule and increasing convenience to change over installation with high accuracy and cleanliness

• All electrical controls including PLC control system and touch screen are enclosed in a separate S.S.304 cabinet like the profile shows or typically designed in construction.

• A special cam design system in combination with pressure pulverization oil pump guarantees the sufficient lubrication to cam trough, decreasing abrasion, thus extending the service life of spare parts.

• Extended dosage disc in size ensures uniform powder flow inside and accurate powder filling.

• Extended cam separation mechanism ensures the turret and main machine run in smooth condition all times, guaranteeing the stability of mechanical drive and accuracy of powder filling.

• Equipped with safety device doors, it will automatically stop while opening the plexiglass door for inspection and maintenance.

• Adoption of capsule vacuum orientation mechanism leads to 99% capsule filling rate.

• Main cam lever supported with double bearing improves the chute dosage plate regulating mechanism. It features dosage plate datum line based on the lower plane, three-dimensional regulating mechanism, uniform space, ensuring the stable powder dosage with high accuracy.

• Attached with separate water-cycling vacuum pump and dust collector for powder collection while capsule opening, cleaning brushes and capsule moulds changeover etc.

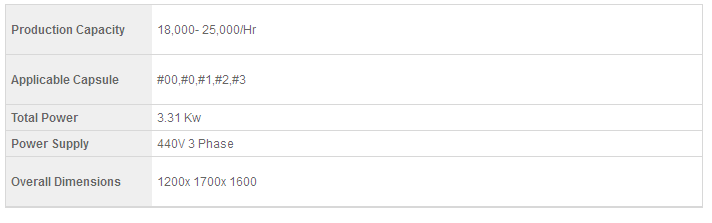

Technical Specification

Description

Description

The machine is used to improve the surface finish of the capsules by polishing the powder from the surface which is deposited during the filling operation.

Construction

Made of SS 304 confirming to GMP Norms. The Machine has one central cleaning chamber made of SS perforated sheet thus eliminating the need of cloth. The chamber consists of a cleaning brush which is mounted on bearing and the speed is controlled through Variable Frequency Drive for optimum cleaning results. The machine is very easy to clean and maintain. The machine can be a standalone polisher or can be attached to a sorting unit.

Features

• The machine has a Stainless steel mesh hence eliminating the need of mesh cloth required for GMP norms.

• The speed of the brush is controlled through a VFD hence making the machine suitable to clean all type of powders.

• The specially designed brush and bristles give very effective results.

• The machine is extremely easy to clean.