Classifier

TNBi offers a comprehensive range of classification solutions to meet particle sizing requirement.

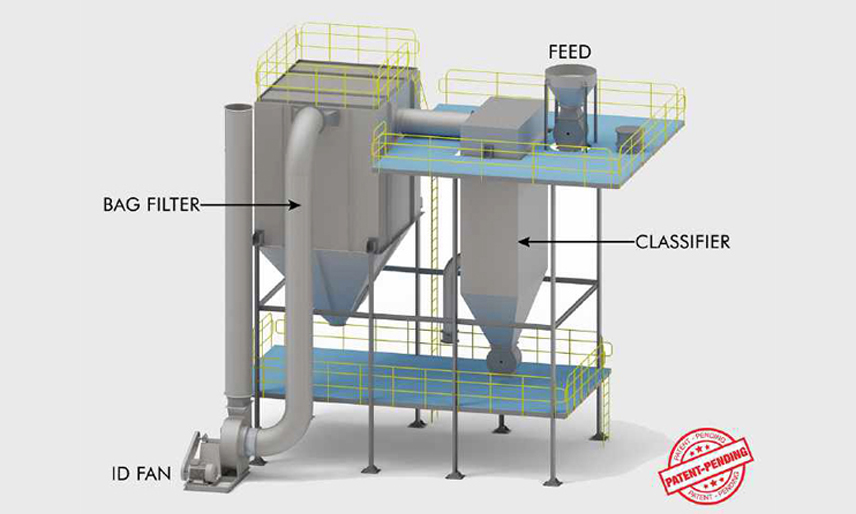

Material enters in classifier with high velocity, to separates particles at cut point 2 to 300 micron. TNBi classifier consist with secondary air arrangement to separate the particle to customer requirement.

Capacity – 100 Kg/Hour to 300 Tons/Hour

Working Principle

- Gas along with Powder enters in classifier.

- Smaller particles gets separated due to centrifugal force.

- The fine tuning in particles separation is done using secondary air.

- Coarse particles gets collected at bottom of classifier.

- Fine separated particles leaves classifier and can be collected in Cyclone and/or bag filter.

- Descritive Image

- Advantages

- Application

Descritive Image

Advantages

- High Reliability - Constant product output

- No moving parts, No wear & tear

- Low operating cost

- Low Installation Cost

- Easy adjustment for separation efficiency

- Can be installed In Series

- Low maintenance cost

- Spare parts not required

- Can handle combustible dust

- Low choking issues

- Can be installed in process line.

Descritive Image

- Mill / Grinder Outlet particle separation

- Powder Processing

- Fly Ash Classification

- Paint & Pigment

- Food & Pharma

- Sand Classification

- Powder Chemicals

- Spices

- Cement Classification

- Graphite

- Plastic Pellets

- Mining

- Metals Powder

- Fertilizer

- Granite

- Alumina

- Many More....