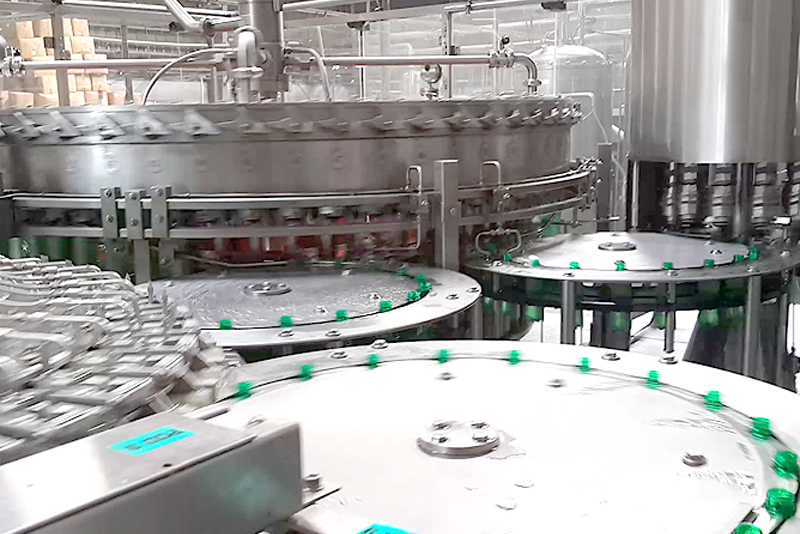

Pet Filler Machine

Pet Filler Machine Features and Details

Hilden Packaging provides best Filling Machines for your business. Here we have listed some important features of Hilden's Automatic Liquid Pet Filler Machine. With these great features of Pet Filling Machine you can get best performance for your Fully Auto Pet Bottle Rinsing Filling and Capping Machine, Mineral water plant.

- Intelligent Machine PLC control with Colour touch Screen 7.5/12.5 Inch for Data logging.

- Introducing the Ultra valve with 2 Snifts one used for Pre-evacuation thus extremely hygienic design for extensive life of the product.

- Ultra CSD valve capable of filling Beer/Soft drinks/Carbonated Pulpy Juices too as there is no mesh.

- All Machine moving parts Like Rinser Bracket/Lift cylinder handling the PET Bottle neck Run are Water Lubricated. Some bearing components are manufactured from the finest engineering polymers.

- Easy lift sliding doors with safeties ensure no accidents occur.

- Interactive intelligence by means of a huge TFT Colour touch screen with all necessary alerts via real time clock & Trouble shooting

- Bottles are neck handled with extremly smooth transfer without scratches even at high speeds.

- Cleaning in position(CIP) is by special CIP bottles. State of the art latest design cap elevator cum orientor system, eleminating blowers subsequent cap contamination.

| NO. | MODEL | FILL-FIZZ (Carbonated Bev.) | |||||

|---|---|---|---|---|---|---|---|

| R/F/C | 200 ml | 500 ml | 600 ml | 1500 ml | 2000 ml | ||

| 1 | 12/12/4 | 70 | 45 | 60 | 22 | 18 | |

| 2 | 16/16/6 | 90 | 55 | 70 | 25 | 22 | |

| 3 | 20/20/6 | 120 | 70 | 80 | 35 | 25 | |

| 4 | 24/24/8 | 140 | 85 | 90 | 40 | 30 | |

| 5 | 24/30/8 | 180 | 130 | 120 | 60 | 40 | |

| 6 | 30/30/10 | 200 | 140 | 130 | 70 | 45 | |

| 7 | 40/40/10 | 240 | 175 | 175 | 90 | 70 | |

| 8 | 40/50/12 | 300 | 240 | 225 | 120 | 90 | |

| 9 | 40/60/14 | 400 | 300 | 280 | 150 | 130 | |

| 10 | 50/70/14 | 450 | 400 | 325 | 175 | 150 | |

| 11 | 60/80/20 | 500 | 425 | 350 | 190 | 180 | |

FAQs About Pet Filler

Pet Filler Machine Hilden

Inside of bottles are Rinsed by spraying water or air or both in the rinse Nozzle. Empty bottles are transferred into Pet Filler rotary rinsing section by an inlet neck guide. The bottles are held from their neck and turned upside down by grippers along their axis. After spraying operation, the bottles continue to move upside down for a while to drain the rinsing water out and then turned back to the upright position. The nozzles have” No Bottle - No Spray System” activated only by the presence of bottles by means of an infeed sensor.

The filling operation is carried out by CO pressure ,by means of the latest state of the 2 art ULTRA VALVE (mechanical valve) which has a dual snift, one for pre-evacuation or flushing before filling the bottle, the other snift is for bottle head space snifting. This valve has complete CIP features. This valve fills at a very high speed due to the positive lift mechanism. An option of Flow meter along with a pneumatic actuator valve (electronic filling valve) for extremely accurate fill can be the latest option.

FILLING OF BEER : Double pre-evacuation system is implemented for beer filling applications. it is used to reduce the amount of the air remaining in the bottle after filling. This treatment eliminates foaming during filling and prevents oxidation of product in the mark increasing shelf life of the product.

Different capping heads can be installed on the monoblock machine to apply plastic screw caps, aluminum caps and metal crown corks. Two types of caps can be applied on the same machine in order to have capability to apply different closures.