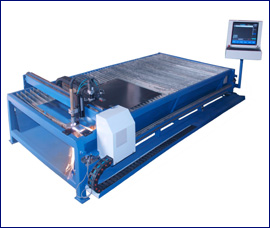

Waterjet Cutting Machine

Waterjet machine uses cold supersonic abrasive erosion to cut almost any materials both metals and nonmetals. The highly pressurized water stream is forced through a tiny area which carries abrasive garnet to erode away the material.

Cutting Table

Size of the table can be selected as per the length x width of the material

Theory

Waterjet machine uses cold supersonic abrasive erosion to cut almost any materials both metals and nonmetals. The highly pressurized water stream is forced through a tiny area which carries abrasive garnet to erode away the material.

Process

Abrasive waterjet and pure waterjet both start with pressurized water, water is pressurizes up to 60,000 p.s.i, or 4100 bar, then is transported to the cutting head where the pressurized water passes through a tiny hole in jewel orifice. The pressure is exchanged for velocity which is what the waterjet cuts with, waterjet actually erode the material they are cutting. After we pass the waterjet stream through orifice, the garnet abrasive similar to that you find on to sand paper is feed through a delivery line which is located on the side of the cutting head, where it is pulled in to the waterjet stream via vacuum effect, and accelerated down the mixing tube. The abrasive garnet is mixed into water-stream and is accelerated like a bullet out of a rifle.

How Water jet Cutters Work

Water jet cutting works by forcing a large volume of water through a small orifice in the nozzle .The constant volume of water traveling through a reduced area causes the particles to accelerate.This accelerated stream leaving the nozzle impacts the material to be cut. The extreme pressure of the accelerated water particles contacts a small area of the work piece. In this small area the work piece develops small cracks due to stream impact. The water jet washes away the material that "erodes" from the surface of the work piece. The crack caused by the water jet impact is now exposed to the water jet the extreme pressure and impact of particles in the following stream cause the small crack to propagate until the material is cut through.

10 Reasons to Choose Abrasive Water Jet Machine

Long regarded as a tool for trained experts, abrasive jets have changed dramatically in the last few years. New technologies have made it possible for just about any machine or fabricating shop to purchase and profitably operate a precision abrasive jet cutting system, with little or no prior experience.

» Wide Range of Materials

The Water-Jet can work with a wide variety of materials, ranging from metals to non metal such as ceramics, composites, glass-even marble and granite.

»Quality Finish

The finish provided by the water Jet Machine is a smooth sandblasted finish. No rough edges, burrs or jagged ends.

» No Heat in Machining Process

Because the abrasive jet uses water and abrasive, the material is not heated up significantly during the cutting process. This makes the Water Jet Machine ideal for materials that are affected or deformed by heat, such as titanium.

» Environment friendly

The Water Jet Machine uses water and garnet to cut. Garnet is an inert gemstone, which can be disposed of in the municipal waste stream. No toxic fumes are produced during machining.

» No tool changing

You don't need to change cutting tools with the Water Jet Machining. One nozzle is used to machine all the different types of materials and shapes, saving time and the expense of multiple cutting tools.

» Minimal burr

Using the abrasive jet, there is little or no burr in most materials.

» Quick to program

The Water Jet Machine comes complete with a comprehensive CAD program (called Layout). You can draw parts from scratch in Layout, or import standard files created in other programs.

» Fast set-up and programming

Make is the other main program provided as part of the DARDI Jet Machine. Make takes the tool path created by Layout and calculates the exact position and cutting speed of the nozzle at a resolution of over 2,000 points per inch (800 points/cm). All you do is specify the material and thickness and Make does the rest.

» Complement existing tools, used for either primary or secondary operations

The Water Jet Machine can also work with your other machine tools to take advantage of the unique capabilities of each. An example of this is roughing out nested parts on the water jet to maximize material usage, and then performing final machining on a mill or machining center.

»Reduce setup times

Little or no side force on the material being machined reduces the need to complex fixtures and greatly speeds setup times.

Technical Specifications

| DWJ Flying Arm CNC Cutting Table Series | Model | DWJ1313-FB | DWJ1425-FB | DWJ1525-FB | DWJ2030-FB | DWJ2040-FB | DWJ2060-FB | DWJ2080-FB | |

| Table Size | 1400x1400 mm | 1600x2600 mm | 1600x2600 mm | 2100x3100 mm | 2100x4100 mm | 2100x6100 mm | 2100x8100 mm | ||

| Travel | |||||||||

| X-axis | 1300mm | 1400mm | 1500mm | 2000mm | 2000mm | 2000mm | 2000mm | ||

| Y-axis | 1300mm | 2500mm | 2500mm | 3000mm | 4000mm | 6000mm | 8000mm | ||

| Z-axis | 150mm | 150mm | 150mm | 210mm | 210mm | 210mm | 210mm | ||

| NC System | Washing 320 W | Fagor / Siemens / PC Based | |||||||

| Positional Accuracy | ± 0.04mm | ||||||||

| Repeat Accuracy | ± 0.04mm | ||||||||

| Traverse Speed | 0~20m/min | ||||||||