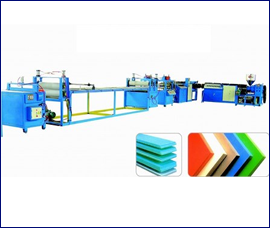

Sheet Line Plant

VARAHII has gained expertise in manufacturing, supplying and exporting a wide range of Multilayer Co-Extrusion Sheet Lines. The products offered by us have rollers hardened and mirror finished surface, which ensure excellent thickness control. Moreover, melt pump is offered for better pressure control for consistent thickness.

Following are the various other features of the product:

• Individually driven vertical / inclined calender unit

• Motorized gap adjustment for calender roll for quick product changes

• Multilayer feed block & flat sheet dies

• Atomization through PLC with touch screen

• Specially designed winding system for jumbo rolls and 2/3 station turret winder

• On-line trim recycling arrangement

• Lowest investment cost per ton of installed capacity

Applications

• Cups & lids for dairy products, yogurt, milk & ice creams

• Drinking cups / glasses

• Containers for fruit, vegetables & sweet packing

• Meal trays for microwave ovens

• Flower pots, transportation trays & agricultural products

Technical Specifications

| Material | Layers | Sheet | Output | |

| Width | Thickness | |||

| PP | 1 Layer | 400 to 1500mm | 0.25 to 2.0mm | 200 to 1200 kgs/hr |

| HIPS/PS | 2 Layer | |||

| PS/HIPS/PS | 3 Layer | |||

| PP/Tie/EVOH/Tie/PP | 5 Layers | |||

OTHER SHEET LINE PLANTS :

» R-PET Sheet ExtrusionPlants

» HIPS Extrusion Sheet Lines

» PP Stationery Sheet Extrusion Lines

» Thermoforming Sheet Extrusion Lines

» Optic Sheet Extrusion Lines

» Thick & Wide Plastic Sheet Extrusion Lines