Blown Film Extrusion / Tubing Machine

UNDERSTANDING PROCESS :- Blown Film Extrusion (Film Blowing)

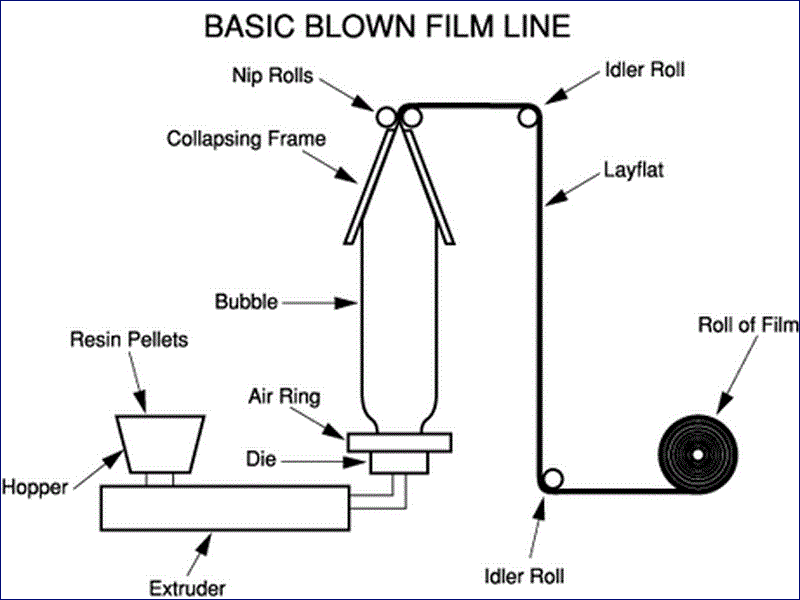

Here we need to provide you little more about the process since its quiet a different machine as compared to the traditional extrusion process machines. Blown film extrusion is the process by which most commodity and specialized plastic films are made for the packaging industry. The film blowing process basically consists of a extruding a tube of molten thermoplastic and continuously inflating it to several times initial diameter, to form a thin tubular product that can be used directly, or slit to form a flat film.

Plastic melt is extruded through an annular slit die, usually vertically, to form a thin walled tube.

Air is introduced via a hole in the centre of the die to blow up the tube like a balloon. Mounted on top of the die, a high-speed air ring blows onto the hot film to cool it.

The tube of film then continues upwards, continually cooling, until it passes through nip rolls where the tube is flattened to create what is known as a ' lay-flat' tube of film. This lay-flat or collapsed tube is then taken back down the extrusion ' tower' via more rollers.

On higher output lines, the air inside the bubble is also exchanged.

Plastic melt is extruded through an annular slit die, usually vertically, to form a thin walled tube.

Air is introduced via a hole in the centre of the die to blow up the tube like a balloon. Mounted on top of the die, a high-speed air ring blows onto the hot film to cool it.

The tube of film then continues upwards, continually cooling, until it passes through nip rolls where the tube is flattened to create what is known as a ' lay-flat' tube of film. This lay-flat or collapsed tube is then taken back down the extrusion ' tower' via more rollers.

On higher output lines, the air inside the bubble is also exchanged.

This is known as IBS (Internal Bubble Cooling)

The lay-flat film is then either kept as such or the edges of the lay-flat are slit off to produce two flat film sheets and wound up onto reels. If kept as lay-flat, the tube of film is made into bags by sealing across the width of film and cutting or perforating to make each bag. This is done either in line with the blown film process or at a later stage.

Typically, the expansion ratio between die and blown tube of film would be 1.5 to 4 times the die diameter. The drawdown between the melt wall thickness and the cooled film thickness occurs in both radial and longitudinal directions and is easily controlled by changing the volume of air inside the bubble and by altering the haul off speed. This gives blown film a better balance of properties than traditional cast or extruded film which is drawn down along the extrusion direction only.

Materials

Polyethylenes (HDPE, LDPE and LLDPE) are the most common resins in use, but a wide variety of other materials can be used as blends with these resins or as single layers in a multi-layer film structure. these include pp, pa, evoh. In some cases, these materials do not gel together, so a multi-layer film would delaminate. To overcome this, small layers of special adhesive resins are used in between. These are known as "tie layers".

Advantages

• Produce tubing (both flat and gussetted) in a single operation

• Regulation of film width and thichness by control of the volume of air in the bubble, the output of the extruder and the speed of the haul-off

• Eliminate end effects such as edge bead trim and non uniform temperature that can result from flat die film extrusion

• capability of biaxial orientation (allowing uniformity of mechanical properties)

• Very high productivity

• Permits the combination of a number of different materials and properties

Applications

Blown film can be used either in tube form (e.g. for plastic bags and sacks) or the tube can be slit to form a sheet.

Typical applications include Industry packaging (e.g. shrink film, stretch film, bag film or container liners), Consumer packaging (e.g. packaging film for frozen products, shrink film for transport packaging, food wrap film, packaging bags, or form, fill and seal packaging film), Laminating film (e.g. laminating of aluminium or paper used for packaging for example milk or coffee), Barrier film (e.g. film made of raw materials such as polyamides and EVOH acting as an aroma or oxygen barrier used for packaging food, e. g. cold meats and cheese), films for the packaging of medical products, Agricultural film (e.g. greenhouse film, crop forcing film, silage film, silage stretch film).

Our Machines

Three layers Blown Film Extrusion Characteristics

1.Die head is layer type spiral mandrel, continuous 360 rotation.

2.Screen pack changer design is reliable, safe in operation and change the fitter screen easier.

3.Various functional parts may be installed to the lies.,such as length counting device, vertical cutting device, cooling water row pipe, film

spreading roller, scrap collecting device.

Three layers Blown Film Extrusion are designed developed by our corporation according to market need, they reach the advanced levels in the 90s, come up with analogous lines in home.

It is optimum designed on the trounds of preference of analogous lines in foreign and home. The lines can be blown cotinuous 800/1500mm in fold width 0.08mm

in the thickness packaging films, film has good insulation, for instance holding temperature, antihumid,antibreeze, anti-rain,anti-rost, insulation oxygen,oil

resistive, and so used for light and heavy-duty packaging, for example fresh fruits, meat-feeding,salt vegetables, fresh milk, drink.

Technical Specifications

| Model | 3SJ-G1000 | 3SJ-G1200 | 3SJ-G1500 |

| Screw Diameter | 55mm*2 60mm*1 | 60mm*2 65mm*1 | 65mm*2 70mm*1 |

| Screw Ratio L/D | 28:1 | 28:1 | 28:1 |

| Screw Speed | 15-150r/min | 15-150r/min | 15-150r/min |

| Main Motor Power | 15Kw*2 18.5Kw*1 | 18.5Kw*2 22Kw*1 | 22Kw*2 30Kw*1 |

| Extrusion Output(Single) | 50kg/h | 80kg/h | 100kg/h |

| Range of Die | 150mm*2 200mm*1 | 200mm*2 250mm*1 | 250mm*2 300mm*1 |

| Single-sided Thickness of Film | 0.01-0.10mm | 0.01-0.10mm | 0.01-0.10mm |

| Max. Folding Width of Film | 1000mm | 1200mm | 1500mm |

| Electric Total Capacity | 76Kw | 88Kw | 102Kw |

| Overall Dimension | 6.6*4.1*5m | 6.8*4.3*6m | 7*4.8*7.5m |

| Weight | 4T | 5T | 6T |

TYPES :

1) Blown Film lines

- PE Blown Film Lines

- PP Blown Film Lines

2) Bag Making Machine

- Plastic Bag Making Machine

- Garbage Bag Making Machine

3) Flexo Printing Machine

- Flexo Printing Machine

4) Cling Film Machine

- PVC Cling Film Blowing Machine

- PE Cling Film Machine

5) Stretch Film Machine

- PE Stretch Film Machine

- PVC Stretch Film Machine

6) Bubble Film Making Machine

- Bubble Fim Making Machine

7) Recycle Machine

- Plastic Recycle machine