Faith Automation has the best talent pool available in India with engineers in the Design Department for Process Planning & Design, in the Automation Department for Controls Design & PLC Programming and engineers in the Robot Simulation Dept. With the help of such an experienced team, Faith Automation provides turnkey solutions in Engineering Services in the field of BIW Body Welding Lines.

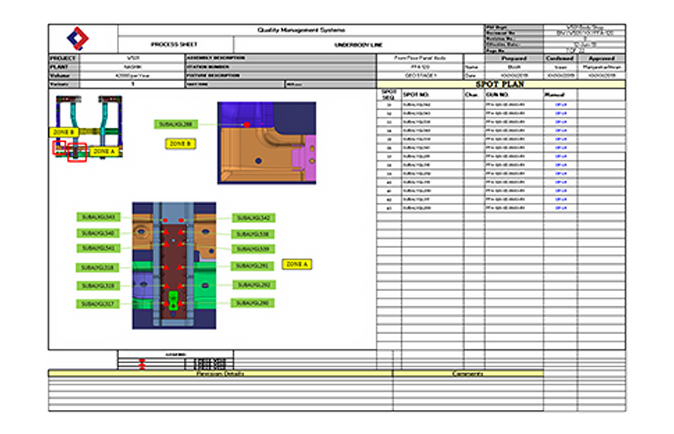

Process Planning

Involves complete body shop planning with the layout, logistics, panel build/flow chart, weld spot selection / distribution, clamping plan / location plan, cycle time study & operator ergonomics study.

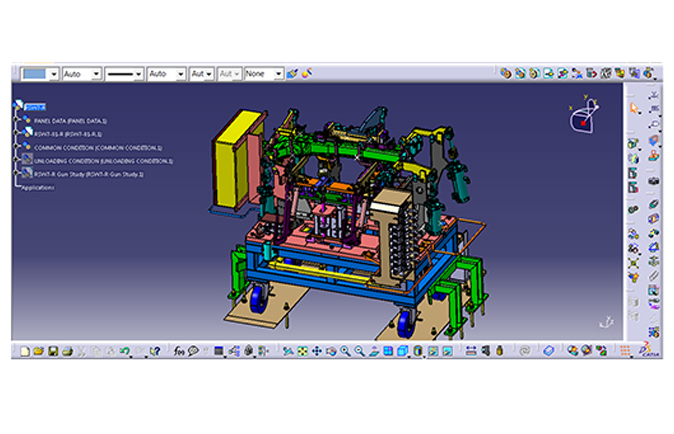

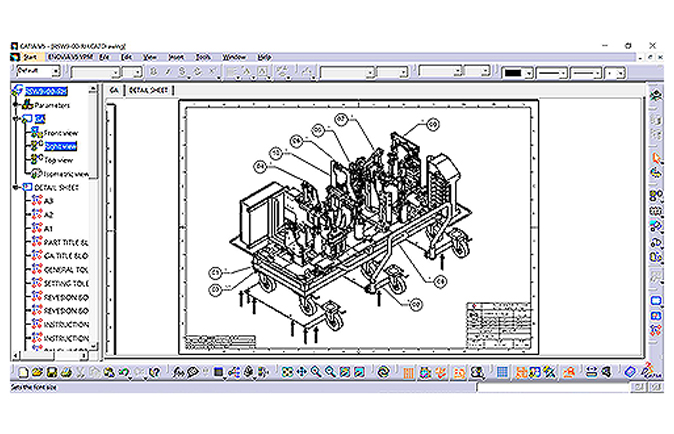

3D Design

Involves designing jigs/fixtures, robot grippers and other equipments as per the plan, required in the BIW welding line. It also includes conducting internal design reviews to optimize the design in terms of its weld accessibility, operator ergonomics and quality. It involves interacting with the Robot Simulation Engineers for Robot reachability with minimum repositions. Finally, its role is in conducting DAP with customer for getting approvals to go ahead for manufacturing.

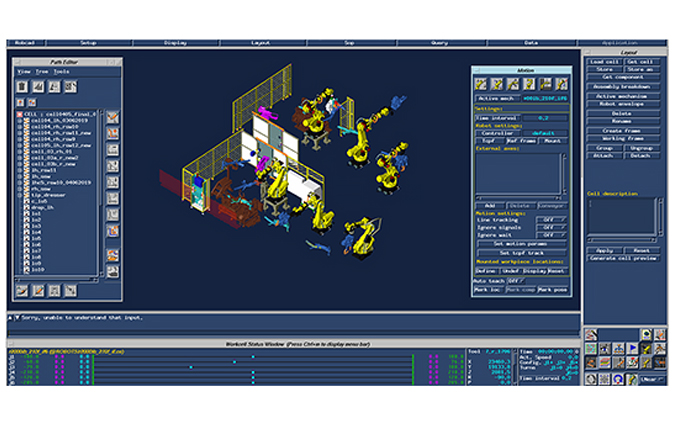

Robot Simulation with OLP Offline Program

The team creates optimized robot cell in terms of the layout space, payload and reachability. This step supports customers in the selection of robots based on the payload and reachability. It creates a robot path, interacts with the design team for any modifications and after finalization, creates OLP (Offline Robot Program) for quick installation of line.

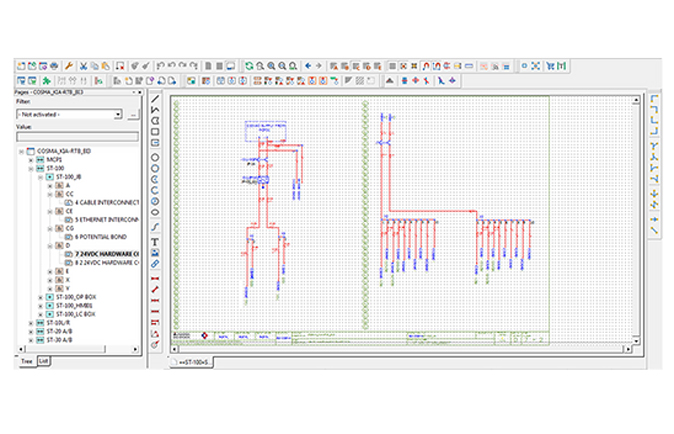

Controls Design

The automation team starts their work on any project from the Controls Design, as per the standards and requirements of the customers. They also create pneumatic circuits for Jigs/Fixtures and get it approved by the customer in DAP.

2D Detailing (Manufacturing Drawing with BOM)

After getting customer approvals on the 3D Designs, we create manufacturing drawings with the BOM (Bill of Material). Also, we support customers with NC Patch Data / IGES models of NC Blocks preparation for manufacturing, inspection data & inspection sheet preparation and preparation of cylinder and sensor sheet (Pneumatic Circuit diagram & Sensor Logic Matrix).

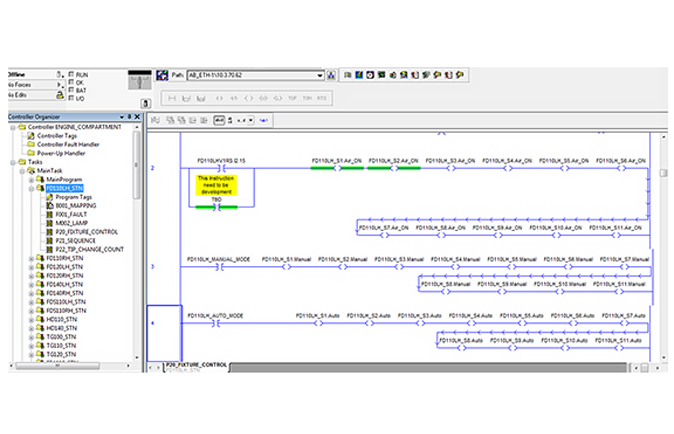

PLC Offline Programming

The team at Faith has many years of experience working with multiple customers. They can work on different PLC’s like Mitsubushi, Allen Bradely, Siemens, Omron, Keyence & Toyopuc for Toyota. This team works in collaboration with the design & simulation team to check all logics, interlocks and zoning for robots, to avoid any changes later.

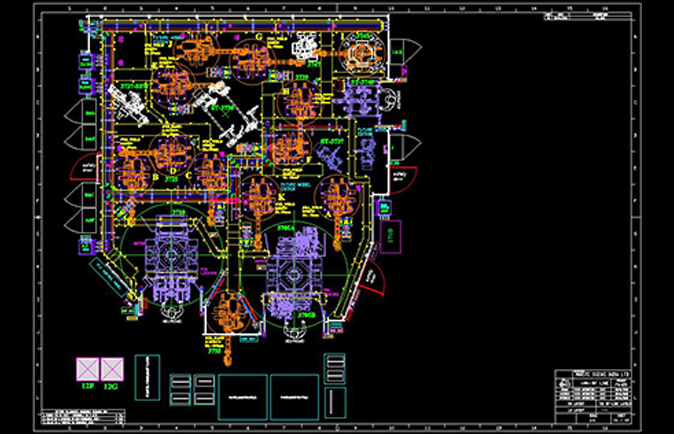

Layout

Based on Process Planning, our Layout Engineers create a complete layout showing all the equipments, panel flow, utilities like power, air & water distribution, safety equipments position along with the safety fence. For more clarity, they create separate layouts for utilities, safety & marking layout for installation purpose.