Innovation is the real source of value. Keeping pace with the ongoing trends, innovative automation offers a more advanced and organized future.The constant increase in the level of automation in projects has aggravated the need of incorporating innovation.Faith Automation is also working towards catering to this format of operations. The organization has developed serveral positioners (3-axis and single-axis), special clamps in fixtures/jigs, lift and shift shuttle conveyor and skid/pallet transfer line.

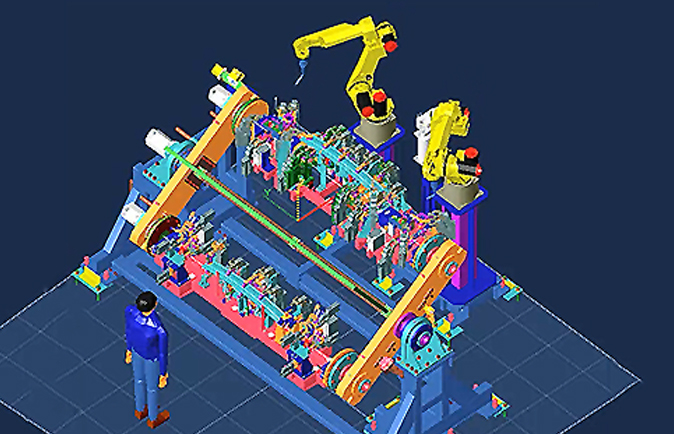

3-Axis Positioners

3-Axis positioners are required specially in case of the MIG welding process for carrying out synchronized welding, for eg. in the Rear Axle-RTB welding between U-Beam & Trailing Arm. When Robots are welding on 1-Trunnion Axis, the operator will be loading on the 2-Trunnion Axis. After both finish their work, then it rotates on the 3-Turntable Axis. These positioners are widely used by Tier-1’s to manufacture the sub-assembly. As it is driven by servo motor, it has got a high precision stopping and speed. Faith develops these positioners based on the requirements and specifications of the customers.

Single Axis Positioners

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

Panel Piercing Solutions BIW Body Shop

Faith has developed many piercing solutions for customers based on their requirements. Manual piercing fixture/jig is planned in case of low volume and small holes to be pierced. For larger diameter holes, where high force is required, the organization developed hydraulic piercing fixtue/jig. Faith has also delivered pneumatic piercing fixture/jig for customers, where hydraulic power packs are not required. It is also better in terms of maintenance of the equipment.

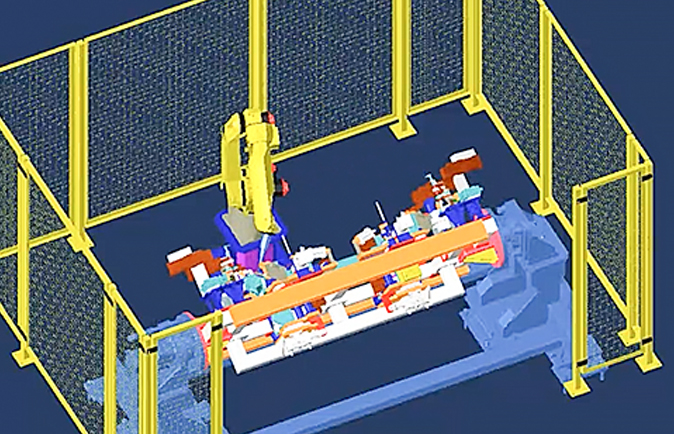

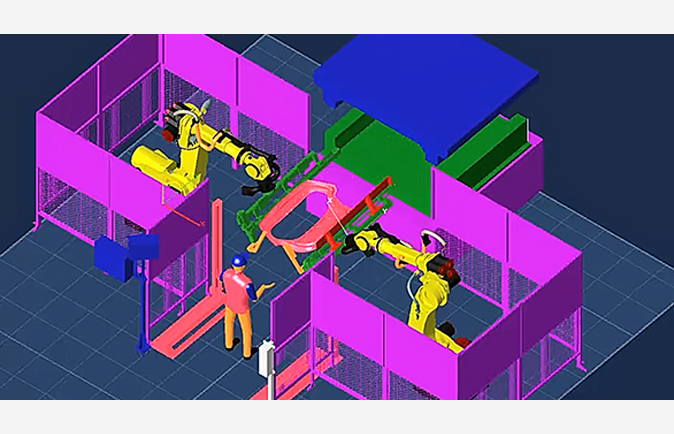

Multi-Model Take-IN & Take-OUT for Press Hemming

For making spare doors, where there is more cycle time available as it is low volume. Faith has developed Robotic Solution for a Japanese customer to feed-in and take-out Multimodel Closures(front door LH/RH, Rear door LH/RH, Hood and tail gate) from the press for the hemming operation. As it is a Robotic Solution, any number of different types of Closures can be planned for making the spares.

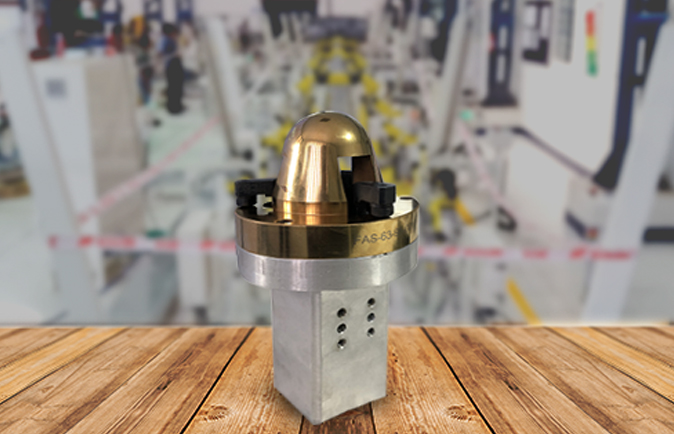

Special Clamps

In the Jigs/Fixtures, Faith sometimes need special clamps due to Hole Size or area of clamping, where there is no accessibility or also due to urgent requirement from the customer, where regular clamps cannot be bought. For such situations, the Innovation team has designed & developed special Clamps fulfilling the needs of the customer and the project.