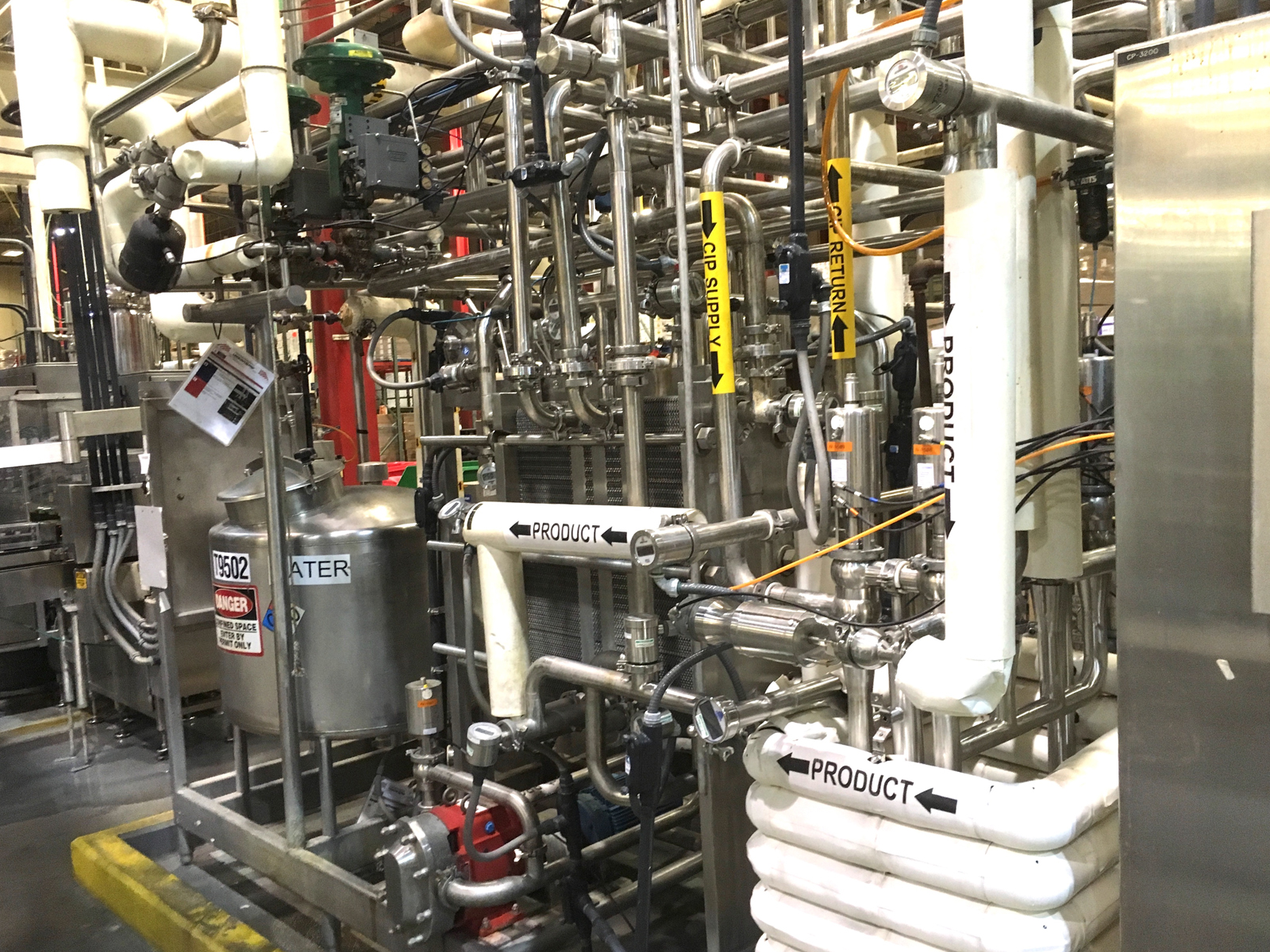

To function as a soft drink maker, you'll need to ensure you have the correct equipment. Soft drink manufacturing is a detailed process that involves infusing water with a number of ingredients such as sugar, essences and even carbon dioxide to carbonate the drinks. The manufacturing process also requires the final product to be filled into the correct packaging, which could be a packet or bottle.Water filtration is an important stage in the soft drink manufacturing process to ensure that the water used to make the drinks is treated and cleansed to meet quality-control standards. Manufacturers use filtration equipment to filter the water and test that it meets the requisite purity percentages. The water is then piped into large stainless steel mixing tanks where it is mixed with the other ingredients use to manufacture the soft drinks such as sugar and flavor. In addition, drinks are carbonated by adding carbon dioxide and cooling the resultant mixture in ammonia-based refrigeration systems.We provide all equipments related to the carbonated soft drinks plant.

| Usage/Application | Carbonated Soft Drinks |

| Brand | Goodone |

| Capacity | 100 LPH to 100000 LPH |

| Packaging Type | Pet bottle,Glass |

| Machine Type | Automatic, Semi-Automatic |

| Material | Stainless Steel |