Minimum Order Quantity: 1 Number

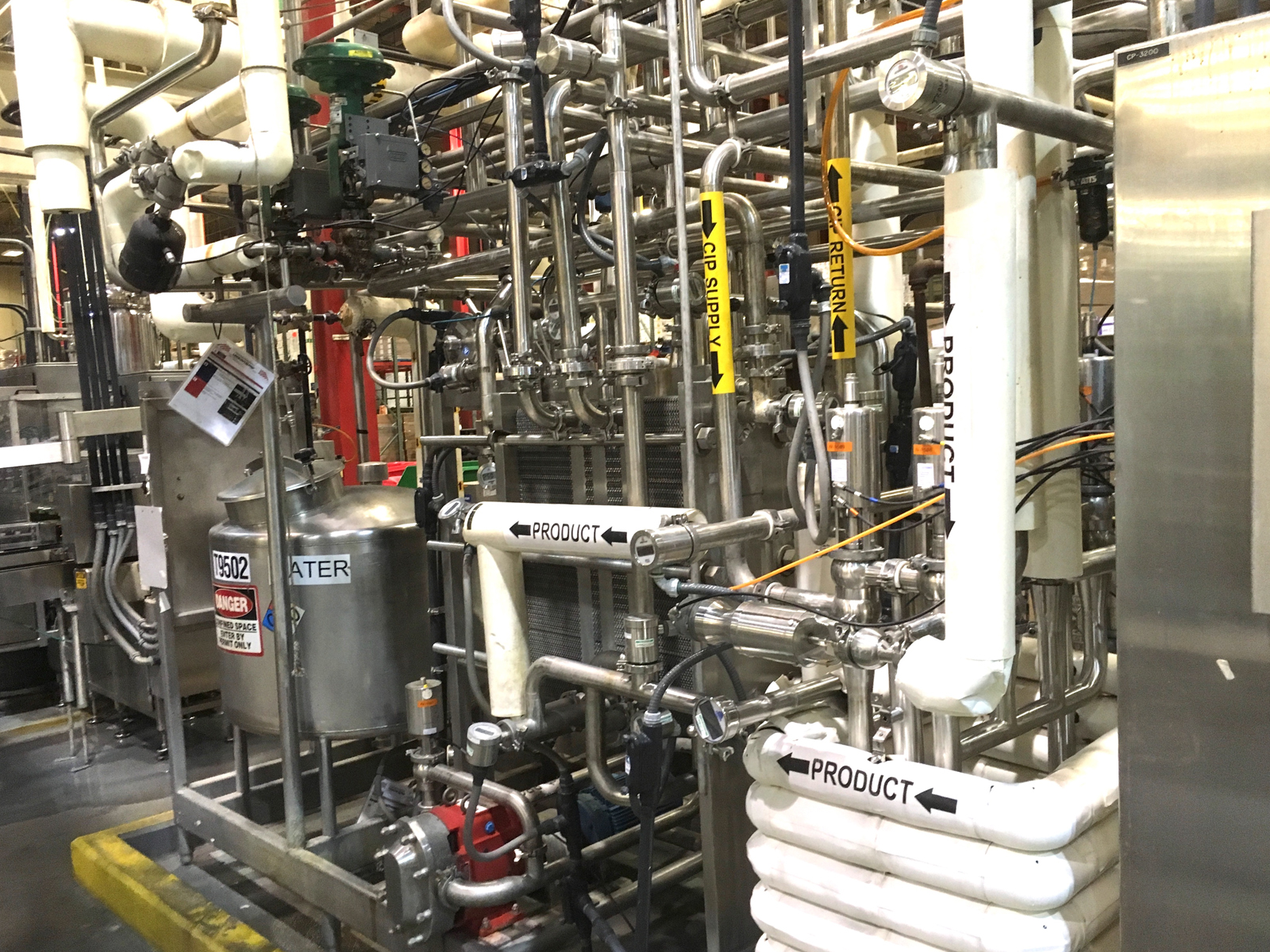

Pasteurization or pasteurisation is a process in which certain packaged and non-packaged foods (such as milk and fruit juice) are treated with mild heat,usually less than 100 °C (212 °F), to eliminate pathogens and extend shelf life.The process is intended to stabilize foods by destroying or inactivating organisms and enzymes that contribute to spoilage,including vegetative bacteria but not bacterial spores. Since Pasteurization is not sterilization, and does not kill spores, a second "double" pasteurization will extend the quality by killing spores that have germinated.The process was named after the French scientist Louis Pasteur, whose research in the 1880s demonstrated that thermal processing would inactivate unwanted microorganisms in wine.Spoilage enzymes are also inactivated during pasteurization. Today, pasteurization is used widely in the dairy industry and other food processing industries to achieve foodpreservation and food safety.Most liquid products are heat treated in a continuous system where heat can be applied using a plate heat exchanger and/or the direct or indirect use of hot water and steam.

Due to the mild heat,there are minor changes to the nutritional quality and sensory characteristics of the treated foods. As per the customer requirement we Design and Manufacturer Pasteurization system for Juice,Milk,Vegetable,chocolate. We have fully automatc PLC based pasteurizer as well as semi automatic PID based pasterurizer.

| Applicable Fruits | All |

| Usage | All |

| Automation Grade | Automatic |

| Brand | Own Design and Manufacturing |

| Capacity | 250 LPH to 20000 LPH |

| Design Type | Standard, Customized |

| Equipment Type | Pasteurizer |

| Heating Medium | Steam or Hot Water |

| I deal in | New Only |

| Installation Service | Yes |

| Machine Body Material | SS304 and SS316 |

| Material | Stainless Steel |

| Operating Pressure | 2 to 5 Bar |