Minimum Order Quantity: 1 Number

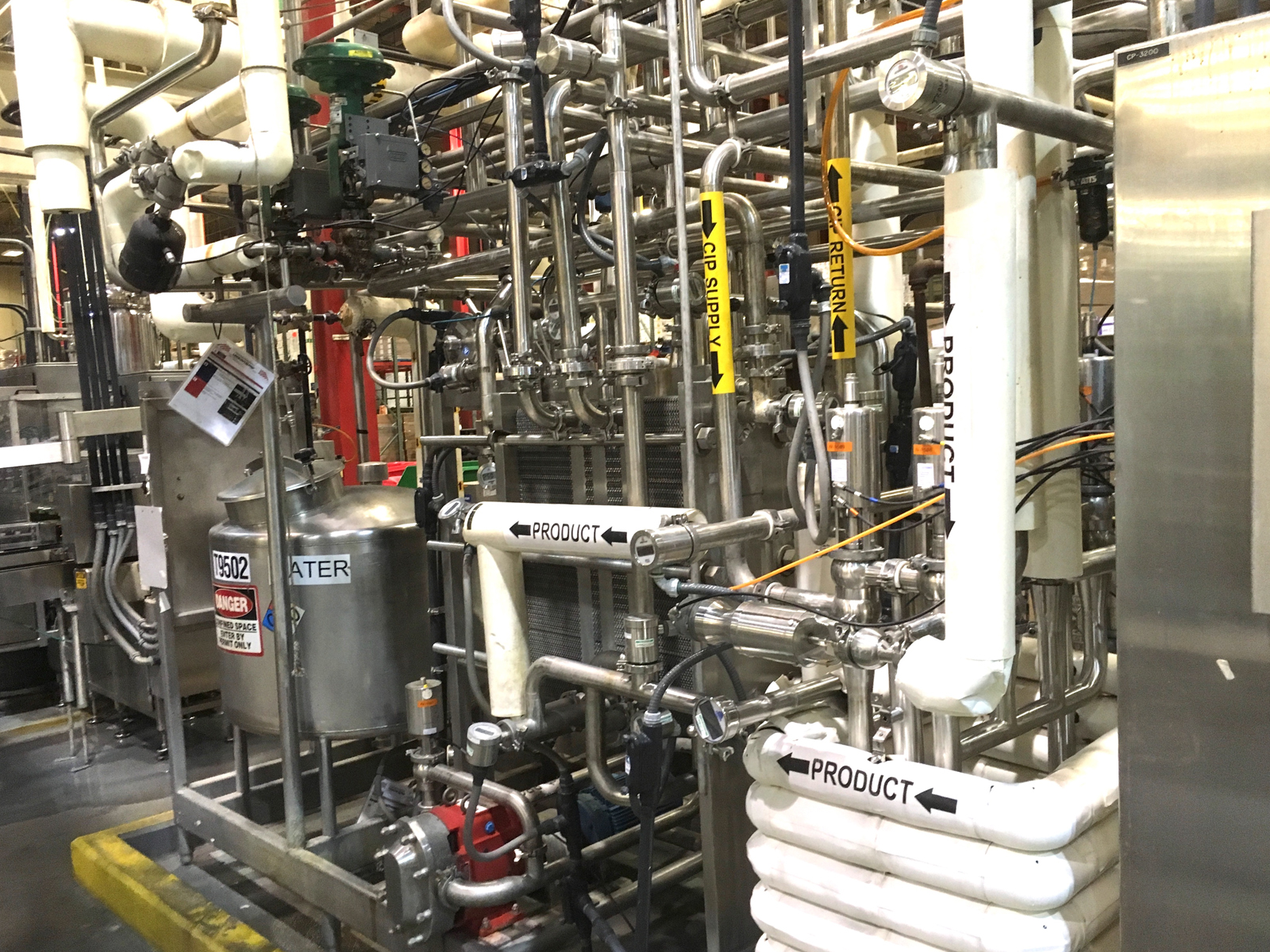

Clean-in-place (CIP) is a method of cleaning the interior surfaces of pipes,vessels, process equipment, filters and associated fittings, without disassembly.Up to the 1950s, closed systems were disassembled and cleaned manually. The advent of CIP was a born to industries that needed frequent internal cleaning oftheir processes. Industries that rely heavily on CIP are those requiring high levels of hygiene, and include: dairy, beverage,brewing, processed foods, pharmaceutical,and cosmetics.The benefit to industries that use CIP is that the cleaning is faster, less laborintensive and more repeatable, and poses less of a chemical exposure risk. CIP started as a manual practice involving a balance tank, centrifugal pump, and connection to the system being cleaned.Since the 1950s, CIP has evolved to include fully automated systems with programmable logic controllers, multiple balance tanks, sensors, valves, heat exchangers, data acquisition and specially designed spray nozzle systems. Simple,manually operated CIP systems can stillbe found in use today.Depending on soil load and processgeometry, the CIP design principle is oneof the following:

A concentrated cleaning solution will clean a Factors affecting the effectiveness of the cleaning agents dirty surface much better than a dilute one due to the increased surface binding capacity.Contact time of the cleaning solution. The longer the detergent contact period, the higher the cleaning efficiency. After some time, the detergent eventually dissolvesthe hard stains/soil from the dirty surface.Pressure exerted by the cleaning solution(or turbulence). The turbulence creates anabrasive force that dislodges stubborn soil from the dirty surface.Groundwater sources Originally developed for cleaning closedsystems as described above, CIP has more recently been applied to groundwater source boreholes used for high end-usessuch as natural mineral / spring waters,food production and carbonated soft drinks (CSD).Boreholes that are open to the atmosphere are prone to a number of chemical and microbiological problems, so sources for high end-use are often sealed at the surface (headworks). An air filter is builtinto the headworks to permit the borehole to inhale and exhale when the water level rises and falls quickly (usually due to thepump being turned on and off) withoutdrawing in airborne particles or contaminants (spores, molds, fungi,bacteria, etc.).CIP is commonly used for cleaning bioreactors,fermenters,mix vessels,and other equipment used in Biotech manufacturing,pharmaceutical manufacturing,and food and beverage manufacturing.CIPis performed to remove or obliterate previous cell culture batch components.it is used to remove inprocess residues,control bioburdon,and reduce endotoxin levels within processing equipments and systems.CIP with a combination of heat ,chemical action ,and Turbulent Flow.

| Usage/Application | Cleanining Vessels and process line |

| Capacity | 10 L-10 KL |

| Brand | Goodone |

| Frequency | 50Hz |

| Material | Stainless Steel |

| Power | 2.2kw to 18kw |

| Voltage | 380V |

| Weight | 200 to 2000 Kg |