Sequential batch Reactors ( SBR Tchnology)

SBR is an activated sludge wastewater treatment system for removing dissolved and suspended organic materials and nutrients. In SBR all the unit operations such as aeration, settling and decanting are achieved in a single reactor, all by automatic operations. Due to this new technology industrial wastewaters can now be treated biologically in ideal conditions, regardless of flow or load variations. Phosphorous and nitrates can be removed biologically as well.

SBR is an activated sludge wastewater treatment system for removing dissolved and suspended organic materials and nutrients. In SBR all the unit operations such as aeration, settling and decanting are achieved in a single reactor, all by automatic operations. Due to this new technology industrial wastewaters can now be treated biologically in ideal conditions, regardless of flow or load variations. Phosphorous and nitrates can be removed biologically as well.

SBR Operation Philosophy

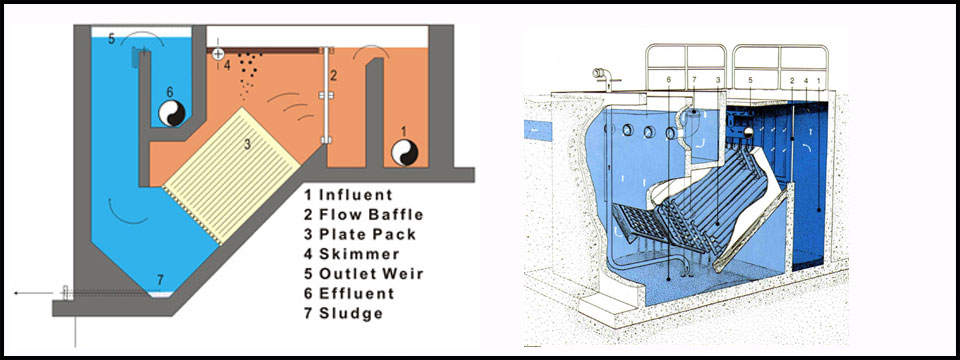

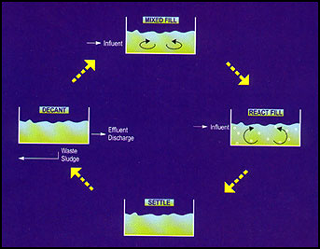

Sequencing Batch Reactor actually represent a very elementary form of treatment process known as "Fill and Draw". Wastewater added to a reactor is treated to remove undesirable component, and is subsequently discharged. The SBR reactor is a self-contained system incorporating equalization, aeration and clarification, within the confines of a SINGLE basin.

Sequencing Batch Reactor actually represent a very elementary form of treatment process known as "Fill and Draw". Wastewater added to a reactor is treated to remove undesirable component, and is subsequently discharged. The SBR reactor is a self-contained system incorporating equalization, aeration and clarification, within the confines of a SINGLE basin.

The SBR uses the latest biomass conditioning technology. This enable the SBR system to attain nutrient control without the addition of chemical and to out perform continuous " flow through systems".

Operation :

Normally the process follows the basic steps of; AERATE, SETTLE and DECANT. The actual cycle time will vary with the sewage results desired. If only BOD reduction is desired, a cycle time as 3 hours may be used. If further treatment, to obtain nitrification / denitrification f. e. is required, the cycle time can be extended to accommodate the process requirements.

The AERATE phase in the SBR system is typically time/level controlled and can be adjusted depending on the required removal efficiency. The AERATE phase is followed by the SETTLING PHASE. The settling represents the quiescent phase during which no aeration or mixing occurs and is also time/level controlled. The last step is the DECANT step representing the discharge of clarified sewage controlled by level in the reactor.

• Aeration phase : Depending on capacity (max 4hrs)

• Settling phase : Normally 45 to 60 minutes

• Decant phase level within 30 min : Reduction from maximum to minimum

Disinfection :

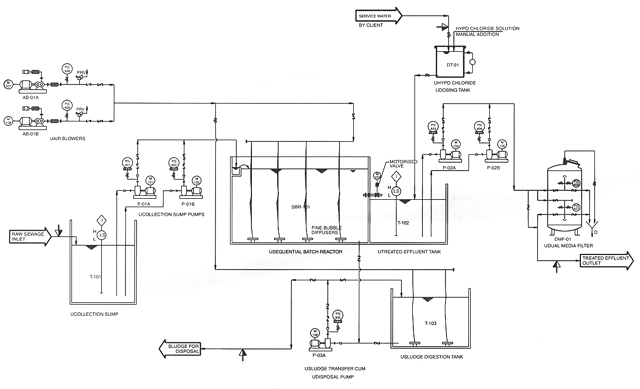

Disinfection of sewage in the above sump will be done using Hypochlorite solution. For Hypochlorite tank and dosing pump will be provided.

Sludge Removal :

Sludge produced is less and is totally digested and hence has no odor. The sludge is removed by means of submersible pump in the SBR Reactor. The frequency of sludge removal will be once in a month (minimum) to a maximum of 3 months. The sludge can be dewatered using sludge drying beds or other dewatering device or can be directly applied as manure.

Typical Flow Diagram

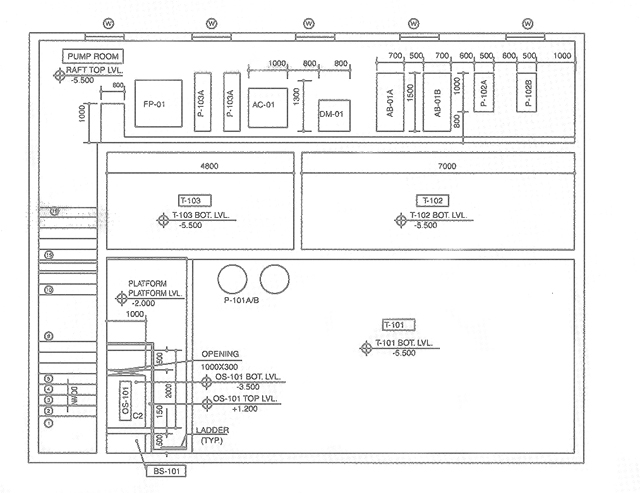

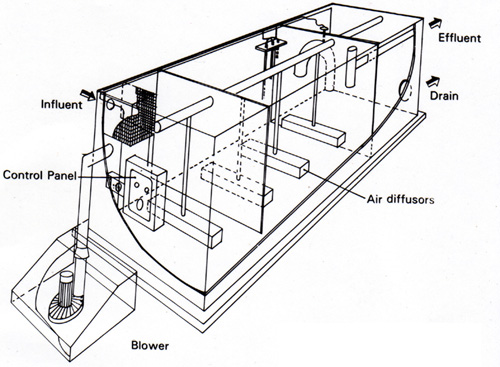

Typical SBR Layout

Standard Units

| Type | POP. EQ | Plant Capacity | L(m) | W (m) | Ht (m) | Inst.Kw |

| K-CON10 | 75.00 | 10Cum/Day | 2.00 | 2.30 | 2.40 | 1.10 |

| K-CON20 | 150.00 | 20Cum/Day | 3.70 | 2.30 | 2.40 | 1.60 |

| K-CON30 | 250.00 | 3OCum/Day | 5.40 | 2.30 | 2.40 | 1.60 |

| K-CON40 | 300.00 | 40Cum/Day | 7.20 | 2.30 | 2.40 | 1.60 |

| K-CON50 | 400.00 | 50Cum/Day | 9.50 | 2.30 | 2.40 | 2.20 |

| K-CON60 | 450.00 | 60Cum/Day | 11.30 | 2.30 | 2.40 | 2.20 |

| K-CON70 | 500.00 | 70Cum/Day | 13.20 | 2.30 | 2.40 | 3.70 |

| K-CON80 | 600.00 | 80Cum/Day | 8.70 | 2.30 | 4.00 | 3.70 |

| K-CON90 | 650.00 | 90Cum/Day | 9.80 | 2.30 | 4.00 | 5.50 |

| K-CON100 | 750.00 | 100Cum/Day | 10.80 | 2.30 | 4.00 | 5.50 |

SBR Retrofits

K-Pack engineered SBR systems are available in as many different Physical Plant layouts and many process design schemes. The SBR process gives itself to many existing Plant configurations, which can be retrofitted with SBR components. Up gradation of existing conventional type of ETP's, STP's can be carried out without interrupting the existing process.

K-Pack engineered SBR systems are available in as many different Physical Plant layouts and many process design schemes. The SBR process gives itself to many existing Plant configurations, which can be retrofitted with SBR components. Up gradation of existing conventional type of ETP's, STP's can be carried out without interrupting the existing process.SBR Benefits

• Achieves Nitrification, Denitrification and Phosphorous removal (without chemical addition) in a single reactor.

• Less excess sludge - therefore sludge handling is simpler.

• Hydraulic flexibility - can easily take shock loads.

• Micro organism selection minimises sludge bulking and controls filamentous bacteria.

• Power savings due to lower oxygen requirements.

• Provides the ability to change any unit process at any time - to achieve a required effect.

• High specific rate of separation in sludge blanket cum clarifier unit.

• Simultaneous nitrification without extra cost.

• No odor problems.

• Reduced operation & maintenance costs.

• No clarifier - further reduction in space and capital cost.

• No sludge recycling - further reduction in 0 & M cost.

• Fully automised - further reduction in operating cost.

SBR Applications

• Small Communities and Housing Colonies

• Townships

• Hotels and Resorts

• Schools & Universities

• Defence and Military camps

• Industrial and Manufacturing area

• Municipalities

Recycling of Sewage/ Grey water in Hotels & Apartment

SBR is an activated sludge wastewater treatment system for removing dissolved and suspended organic materials and nutrients. In SBR, all operations such as aeration, settling and decanting are achieved in a single tank.

Sewage and/or Grey water is fed through a screen to remove large solid waste, and then to the SBR tank where by aeration all dissolved impurities are removed. It is then passed through a sand filter to remove any traces of solids. The treated water is then disinfected by dosage od Hypochlorite solution, an dis then ready for reuse.

Sludge produced in the SBR system is much less an dis totally digested and hence has no odour. This sludge after 2-3 months can be used directly as manure. The SBR uses the latest biomass conditioning technology, enabling the system to attain nutrient control without chemical addition. These systems are engineered in many different layouts, either underground or above ground depending on site conditions. In existing apartment blocks, these systems can be easily installed with a minimum of piping rerouting, and can be integrated with the existing water circulation system easily and cheaply.

Advantages :

• Compact, space saving

• Power savings due to lower Oxygen use

• No odour problems

• Reduced operation & maintenance costs

• Modular system

• Treated water reused for washing,gardening etc