Conduction Dryers

This range of dryers employ the conduction mode for drying. These dryers ensure low temperature, gentle drying of the product. Conduction dryers are designed taking into consideration the wet and dry product flow characteristics, lump crust formation tendency and thermal sensitivity of the product in dry condition.

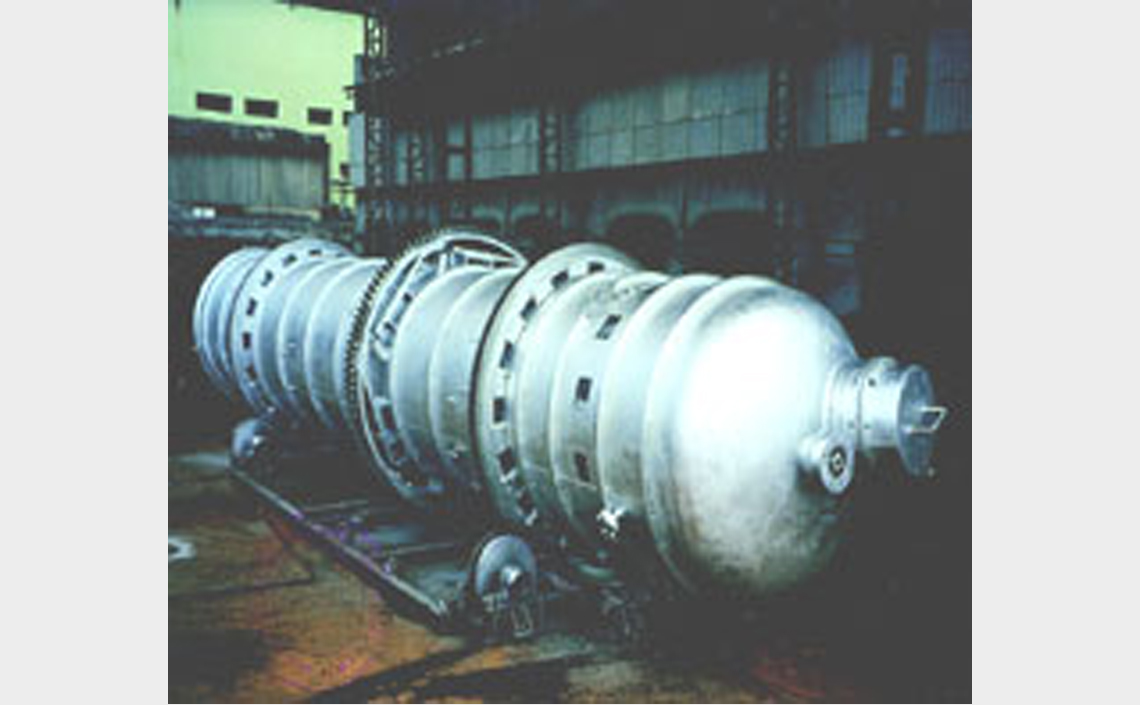

Indirect Steam Tube Rotary Dryer

Indirect Steam Tube Rotary dryer comprises of tubes fixed to a rotating shell. Steam is passed through the tubes. The wet material present in the rotary shell is lifted by means of spiral flights and showered on the steam heated tubes. The product is dried by means of the indirect contact with steam. The entire shell is supported on rollers and rotated by means of girth gear.

The sealing arrangement is provided to have minimum air leakage and product losses.

Advantages

- Rugged construction

- Continuous operation

- Gentle drying of material

- Thermally efficient

- Low operating & maintenance cost

Rotary Tube Bundle Dryers

A Tube Bundle is like a heat exchanger, rotated in a stationary insulated housing. Lifters provided on the tube bundle lift the material and shower them on the hot tube bundle surface. Steam is passed from one end of Tube Bundle for drying and condensate is removed from the other end.

Advantages

- Gentle drying

- No breaking of material

- High heat economy

- Continuous operation