Scraped Surface

Scrapped surface Evaporator is used for evaporating the heat sensitive material under high vacuum using thin/scraped film technology. Thin film yields high heat transfer coefficients, making the process highly effective.

Our evaporators are ideally suitable for concentrating a range of solutions / suspentions including highly heat sensitive liquids where original properties of the product have to be preserved and the stability of the product is vital.

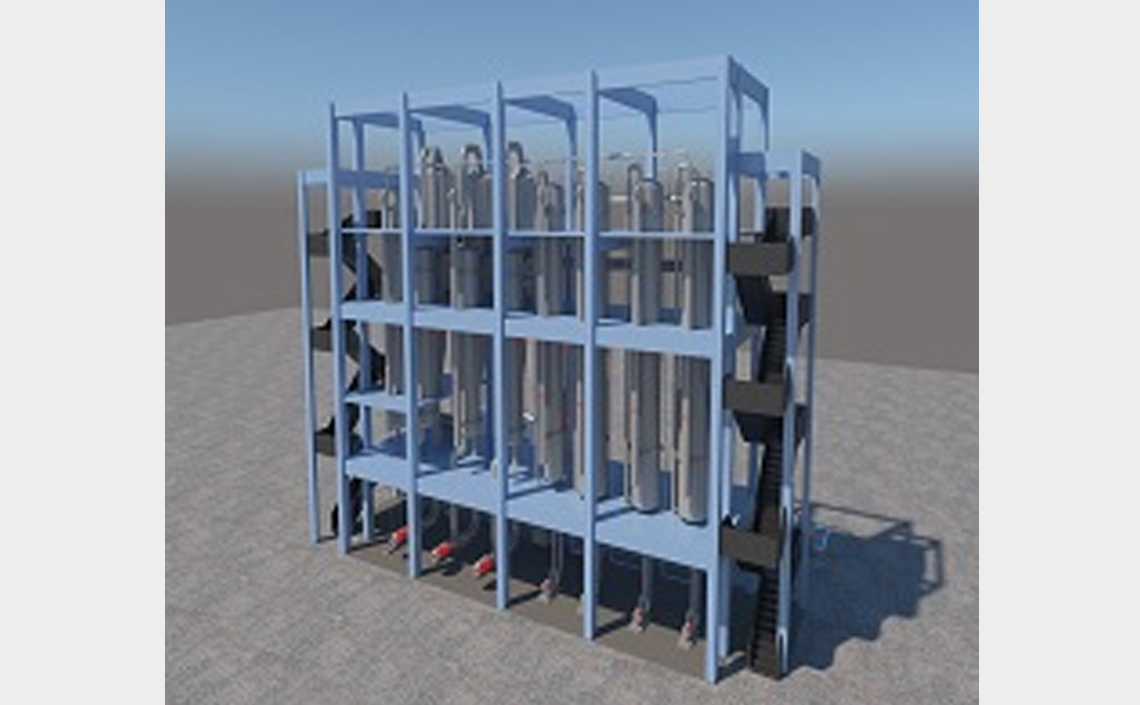

We offer custom built plants, which can be specially designed and sized to optimize the operation cost vis-a-vis the initial investment. Single or multiple effect system using falling film, scraped surface and forced circulation either alone or in combination can be offered to meet product requirements.

The system can be offered as a package unit inclusive of pre-heaters, thermo compressors, vapour separators, transfer pumps, vacuum pumps and condensers and solvent stripping units.

Full Array of Evaporators

We build our evaporators with meticulous design and manufacturing procedures to suit each and every specific application in mind. May it be highly temperature sensitive product or highly fouling and sealing product. Or, it may be a specific requirement of reducing operating costs. All requirements are assessed and need fulfillment is incorporated at the design stage itself.

The appropriate combination of Falling Film, Forced Circulation, Scrapped Surface type Evaporators along with Thermo vapour Re-compressor, Condensate and Product Flashing designed optimally, delivers the best efficiencies and ensures least operating cost.

Accessories

Condensate and product Flashing

By flash pulling the outgoing streams like product and condensate, maximum heat recovery within the system is ensured and that accounts for substantial steam reductions.

Thermo vapour Re-compressor

They ensure reuse of evaporated vapours and thereby account for a good reduction in steam requirement, almost equivalent to one additional effect.

Unique Characteristics

- Low fixed and operating costs

- Optimum heat transfer area

- Good heat transfer coefficients at all temperature gradients

- Easy accessibility and compact layout

- Self cleaning action from salting

- Scaling and fouling

- Large evaporation capacities

- Low temperature operation

- Best suited for clear, foaming and corrosive solution

- High viscosity

- Solvent Recovery

Industry Applications

Chemical Industry

- Dyes

- Dye Intermediates

- Tanning Agents

- Sodium Sulphate

- Glycerol Solution

- Calcium Chloride

Pharmaceutical Industry

- Herbal Extract

- Herbal Extract

- Gelatine

Starch Industry

- Maltodextrine

- Dextrose

- Sorbitol

- Corn Steep Liquor

- Glucose

Food Industry

- Juices

- Milk

- Coffee

Effluent Industry

- Waste water

- RO Reject

Our core strength is our design capability and enhancement through

- Absorbing advancements made in circulating and flash technology and applying them commercially.

- Extensively using Pilot Test facilities available in-house for refinements.

- Better understanding of client requirements and creating all system engineering in-house.

- Extensive use of specially designed software for simulation

Peak Performance is assured by

- One roof manufacturing so that all individual components designed in-house deliver fully the properties they are designed for.

- Thorough testing.

- Formulating designs that ensure long term operation without de-scaling / CIP

Low operating costs come through

- High thermal economy

- Minimized descaling with higher uptime uncomplicated design that makes troubles shooting easy and maintenance fast.