Rotary Dryers

Rotary Dryers are rugged and robust in construction. The solids to be dried are showered in a hot stream of air and dried during travel through the dryer.

Direct Rotary Dryers

Direct Rotary Dryer comprises of a rotating inclined shell through which a hot stream of air flows. The wet material present in the rotary shell is lifted by means of spiral flights and showered in hot flowing air. Due to this direct contact, the product is dried.

Direct Rotary Dryer comprises of a rotating inclined shell through which a hot stream of air flows. The wet material present in the rotary shell is lifted by means of spiral flights and showered in hot flowing air. Due to this direct contact, the product is dried.

The internals are designed to ensure uniform distribution/showering over the entire cross section.

The entire shell is supported on rollers /tyres and rotated by means of girth gear or by means of a friction drive. Sealing arrangement are also provided so as to have a minimum air leakage and product/Thermal losses.

Features

- Ideally suited for large capacity applications and uneven particle size distribution

- Continuous operation and versatile application

- Low operating & maintenance cost

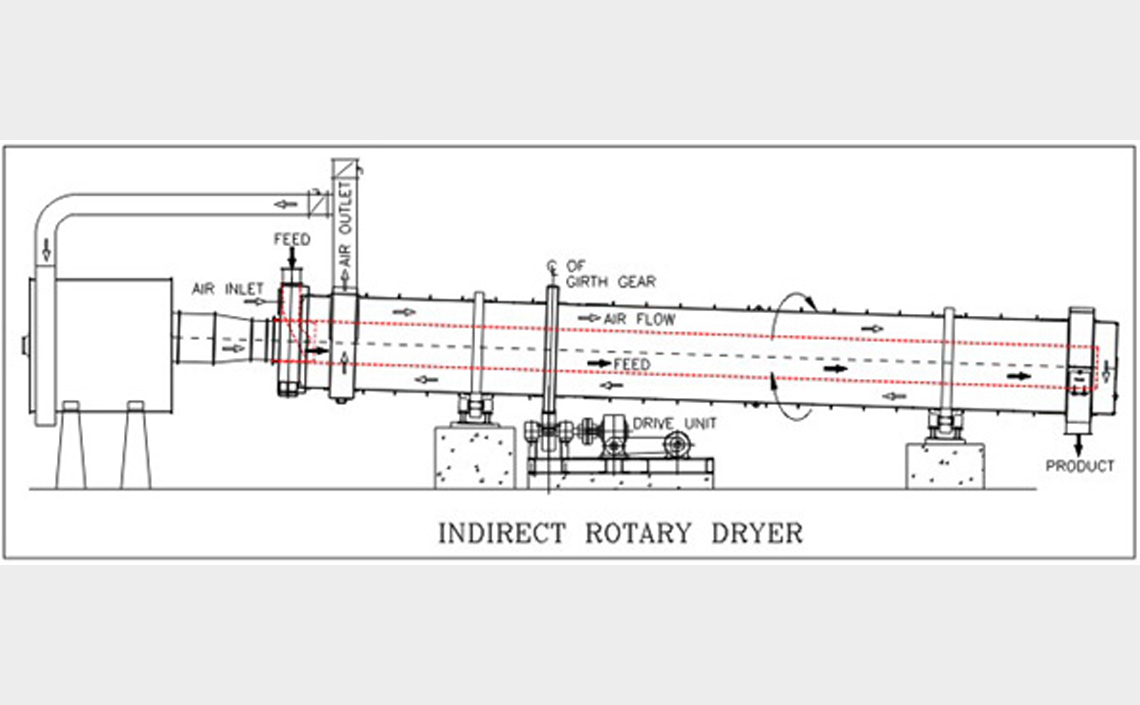

Indirect Rotary Dryers

Indirect Rotary Dryers comprises of a rotating shell having a concentric inner shell. Hot products of combustion passed through the inner concentric shell not coming in contact with the product. The product is dried by radiation and conduction.

Advantages

- Products which can get oxidised or flammable can be dried very easily.

- Continuous operation and versatile application

- Low operating & maintenance cost